Functional printing is leveraging the use of inkjet printing and opening new market opportunities for printhead manufacturers. The manufacturing digital revolution is underway. According Yole Développement (Yole), inkjet printheads integrated in industrial printing equipment are expected to reach more than US$31 million in 2023, with a 30.3% CAGR from 2017 – 2023.

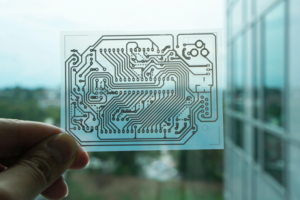

Inkjet printheads stepped up to support manufacturing of TVs, electronic components, and solar cells fueled by the need for fast, low-cost prototyping of printed circuits, as well as technologies able to deposit very thin conductive lines on solar cells without compromising efficiency.

Drop-on-demand (DoD) piezoelectric printheads are the most suitable devices for depositing a picoliter of inks where you want, when you want, and at high frequencies. Compared to thermal ejection, which is largely used in consumer office, and commercial printing, piezo printheads are used in industrial applications because of their higher resistance and longer lifetime in harsh environments. Furthermore, piezo ejection offers more choice in ink selection: for example, aqueous, solvent, and UV-curable inks.

A strong increase in wearables requiring miniaturized, “close to the skin” devices in certain applications, is paving the way for flexible printed electronics. Expensive photolithography processes with mask technology could be replaced by inkjet printing processes to deposit conductive lines on-demand. Inkjet technology demonstrates consistently improving performances in terms of deposition accuracy, high-resolution printing, and droplet volume control. Printheads are one of a printer’s key components, and they’re becoming increasingly complex, requiring strong knowledge and experience.

High throughput printing is now reached with high number of printhead modules in a same printer. It is worth noting that nozzle positioning and well-controlled ejection are key to printer manufacturers and targeted applications. Printhead quality is improved by using MEMS technologies and thin-film PZT (Lead Zirconate Titanate), helping them attain the required level for electronic applications.

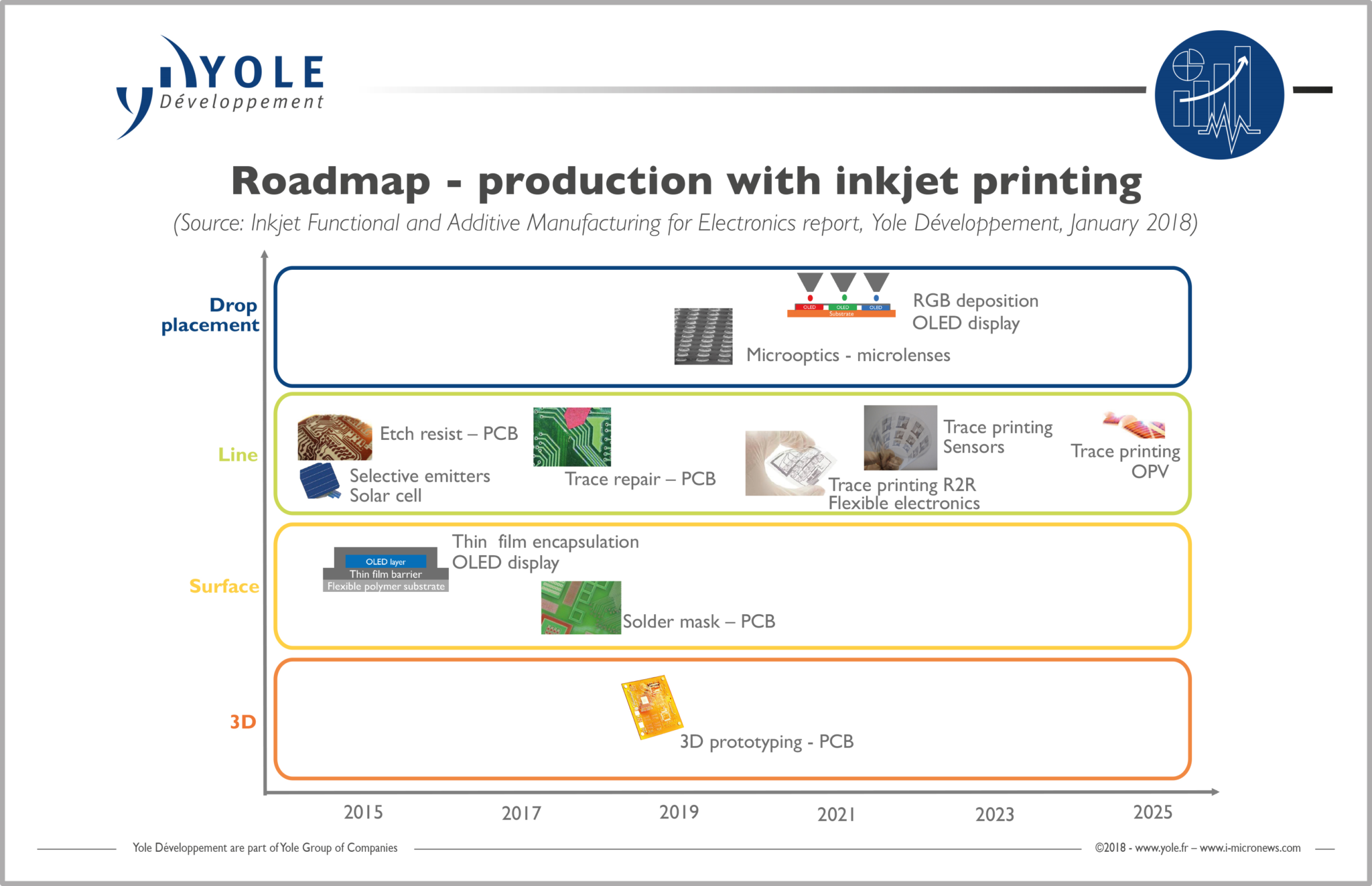

Can inkjet printing manufacture a full electronic device? The answer is yes, but only in prototyping applications. 3D inkjet printing can now manufacture a PCB card prototype from A – Z. Nano-Dimension, a developer of 3D printing equipment solutions, released at the end of 2017 its Dragongfly 2020. In mass applications, inkjet remains one of the key steps in the manufacturing process.

The market research and strategy consulting company Yole, releases this month its Inkjet Functional and Additive Manufacturing for Electronics report, the first research performed on the inkjet printing technology in the field of electronics, micro-electronics and micro-optics. Yole’s analysts propose a comprehensive survey focused on the inkjet printing applicability including major applications today, applications foreseen and related inkjet printing roadmap.