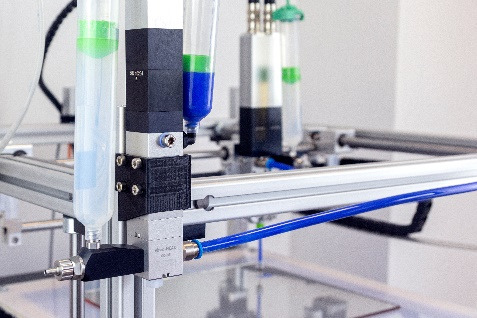

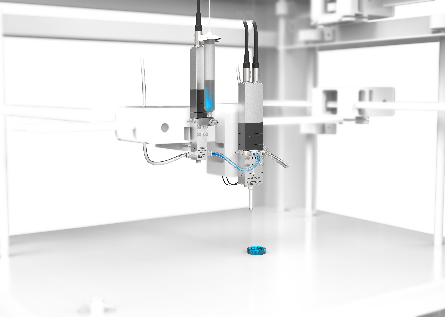

vipro-HEAD color ink delivery system expands ViscoTec 3D portfolio

The trend towards individualization has an impact on both B2C and B2B products. And it does not stop at 3D printing. The call for individual developments and requirements has reached ViscoTec through numerous customers. An extension of the ViscoTec 3D portfolio was developed based upon market requirements: The vipro-HEAD color ink delivery system.

Individual design of 3D printed components is made possible with the ink delivery system. Not only can single-colored or transparent components be created, but also a wide range of colors and designs can be chosen – for the end customer, particularly in the consumer sector.

The new 3D ink delivery system at a glance:

The proven ViscoTec endless piston principle inside the ink delivery system guarantees a precise supply of ink of up to 1 to 3 % to the material (e.g. silicone): The required, and adjusted ink quantity is continuously maintained for homogeneous color lines in the component. The system has a modular design. In the event of an ink change, print heads, that can be purchased individually, ensure complete flexibility in the process. An individual adjustment, for example use of other colors or other color concentrations, can be done very quickly after a simple switch of the print heads.

Existing color pigments from the injection molding sector can be used for the ink delivery system. These inks have already proven themselves in numerous applications.

The advantage of ViscoTec technology:

The purely volumetric dosing of printing materials and inks in the ViscoTec 3D print heads is perfect for highly viscous materials. These are handled precisely, ensuring complete printing process reliability. The color pigments are reliably mixed with the main material in the static mixing tube. This guarantees an optimal design of the finished components.

Setting the automatic suck-back function at the end of a printing process does not have any negative impact, such as color fluctuations in in the component. On the contrary, the suck-back feature ensures a clean dosing process and prevents dripping or stringing of the material.

The ink delivery system process is shown in the video: https://youtu.be/JcbuxQe3BSU