The electronics industry is fast-paced today, and one of the areas companies are most interested in is the development of future technologies. A study conducted by the World Economic Forum revealed that this industry is on its way to achieving new heights. According to this report, the rising reliance on home IoT devices has led to the annually attached devices betting on to the annual 21 billion mouths on lenses attached to contacts. In this regard, technology is a major role player. Those statistics point towards the future of the industry where digital and nano-technologies are and continue to be among the key players that will define the development of modern gadget devices. Thanks to the development of IoT, the majority of the world’s cargo by the next decade, will be delivered by smart carriers, the ViP, signal communication system of ships recycling crews in remote areas, and flyable bustling points for medicine deliveries.

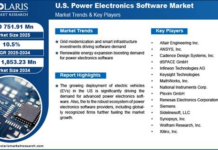

EMS-ODM providers offer a comprehensive service with designing and manufacturing as the main components (ingredients) of the service. Consegic Business Intelligence analyzes that EMS-ODM Market size is estimated to reach over USD 1,164.62 Billion by 2031 from a value of USD 563.72 Billion in 2022 and is projected to grow by USD 599.43 Billion in 2023, growing at a CAGR of 8.7% from 2023 to 2031. Traditionally, EMS companies (electronics manufacturing services companies) have been engaged in the production of electronics products, as per the designs shared by their customers, while ODMs have been producing and designing the products on their own, which could then have the brand of the customer or company chosen by them.

The EMS-ODM hybrid model links up these talents, now a single supplier can deal with the full cycle of a product starting from the initial plans to the last part of the assembly. This way the companies can benefit from the specialized skills of the EMS-ODM providers in engineering the devices, the production is still under the responsibility of the manufacturers, which in turn results in a simplified supply chain with less supervision, fewer partners, and lower operational costs are incurred, hence the final cost is a lower one.

Streamlining the Supply Chain

A major merit of EMS-ODM is its capability to utilize the electronics supply chain by merging design, component sourcing, manufacturing, and logistics into one integrated solution. This minimizes the number of touchpoints in the supply chain, thereby improving efficiency and fostering unity among the various stages of the product’s lifecycle.

EMS-ODM providers can achieve a substantial decrease in the interval from product development to market release by integrating both the design and the manufacturing processes. Companies do not need to waste their time encoding between many vendors or integrating design and manufacturing. Teamwork between the design and production departments ensures that any design accents can be put into production soon and that every part can be manufactured on time.

One way to do this is by consolidating design and manufacturing in a single provider from where companies can benefit from economies of scale. EMS-ODM providers can often buy components at a reduced price through their highly established networks and high-volume purchasing power. Moreover, by incorporating the design and manufacturing procedures, EMS-ODM providers can discover expense-reducing options during the early stage of product development before the final production stage.

The EMS-ODM model provides a larger extent of product developer’s flexibility. The company can pick the ODM’s pre-made items and update them to their brand or get a new model design that fits the market from the EMS-ODM provider. This flexibility gives companies the ability to change direction faster to keep up with new market trends and new consumer demands which in turn help them to remain at a competitive level.

Supply Chain Risk Mitigation

EMS-ODM vendors are a type of solution that helps shift risks when a shortage of the supply chain results in costs for the industry. They are suppliers who usually have business relations with a big collection of other suppliers and are thus able to handle such issues in the supply chain as shortages of components, changes in demand, and political uncertainty. In addition, EMS-ODM providers often have manufacturing facilities in multiple regions, thus enabling companies to diversify their production locations and reduce dependency on a single geographical area. This, in turn, will reduce the risk of any disruption due to things like natural disasters, trade restrictions, or labor issues.

Conclusion

EMS-ODM providers are the key players in the electronics supply chain as they provide an exhaustive solution in which both designing and manufacturing are integrated. Using this method, businesses can save money on costs, speed up the time-to-market process, and gain better flexibility besides the restructuring of the supply chain to minimize risks to their supply-excess problems. It is expected that the electronics sector will keep growing; For this reason, the EMS-ODM concept will continue to be a key thing to succeed in a world market that is becoming complex day by day. Source: EMS-ODM Market