Next2OEM Project:

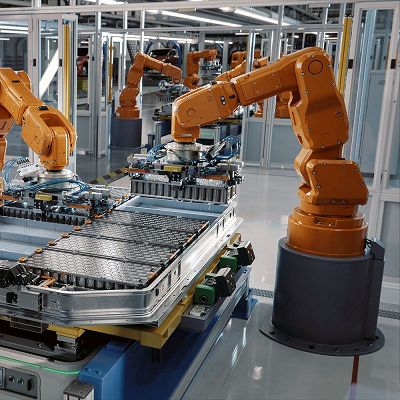

TE Connectivity (TE), a leading global company in connectivity and sensor solutions, is playing a key role in shaping the future of automated vehicle production as an official partner of the Next2OEM research project, funded by the German Federal Ministry for Economic Affairs and Energy (BMWE, formerly Federal Ministry for Economic Affairs and Climate Action – BMWK). The project takes a holistic approach to optimizing the entire value chain of wiring harness systems for automotive applications. As a major innovation milestone, TE contributed to the development of a new connector geometry specifically designed for use in automated manufacturing processes with robotic gripper systems.

The newly developed geometry is part of the “Component Automation” work package in the Next2OEM project. In this area, connectors, cable lengths, and features such as joints, splices, brackets, and sheaths are specifically designed to enable reliable and efficient integration into automated handling and assembly lines. For the first time, the connector design is being standardized to support automated processes—from the supplier all the way to integration into the vehicle at the OEM.The final version of this drawing is currently being finalized and forms the basis for future applications at OEMs and suppliers. The connector geometry has already been presented by TE Connectivity at Wiring Systems Congress and other relevant industry conferences and technical events.. A demonstration video showed the automated handling with gripping technology in a practical way.

“With this development, we are taking our expertise in connection technology to the next level – we don’t just think in terms of electrical performance, but also in terms of automated process chains,” says Stefan Glaser, Director Product Management New Technologies & Standardization Automotive, TE Connectivity Germany GmbH “The great interest from the market confirms that we are addressing a real need.”

This innovation forms a future-ready basis for the scalable and automated use of connectors in automotive production. At the same time, it marks an important step towards end-to-end automation of wiring systems. As an active partner in this development process, TE once again emphasizes its position as a leading technology provider for modern E/E architectures and next-generation mobility in the field of automotive connectivity. “With its advanced level of robotic automation readiness, this innovative gripper interface has the potential to set a new industry standard,” comments Stefan Glaser.

For more information visit TE Connectivity.