OMRON Corporation will globally launch its DX1 Data Flow Controller on September 30. DX1 is an edge controller that can collect, analyze, and visualize operation data of sensors, controllers, and other factory automation devices operating on the manufacturing site, without specialized programs or software.

In recent years on the manufacturing site, on-site data utilization and transition to IoT have grown even more important in the endeavor to pursue productivity and quality while reducing GHG emissions. In reality, however, many emerging barriers are hindering the use of data from manufacturing sites, including issues regarding the standardization of methods for retrieving and using data from devices and equipment, and in securing AI, IoT, and other digital technology talent.

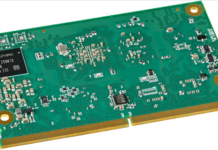

OMRON’s new DX1 Data Flow Controller was created as an edge controller series that works in synergy with OMRON’s uniquely developed Sysmac Automation Platform to collect and visualize data from devices and equipment operating on the manufacturing site. It is the company’s first industrial controller that can collect data from the manufacturing site and enables no-code device configuration.

Aimed to address data utilization issues faced by the manufacturing industry to accelerate digital transformation in the sector, it is focused on usability and connectivity.

With regard to usability, it is equipped with packages, including templates for utilizing critical indicators, that users can readily use on the ground according to their objectives and purposes. Its flow editor is designed to provide an at-a-glance understanding of the data processing flow and enables no-code data flow creation. With regard to connectivity, its enhanced connectivity with programmable logic controllers (PLCs) from multiple Japanese manufacturers allows it to be retrofitted to existing equipment, which means you can seamlessly connect different types of control devices. This helps reduce lead time and initial investment costs upon product implementation.

Advantages of the Data Flow Controller

(1) A quick and easy start to data utilization, for anyone

Standard equipped with data preparation/analysis middleware designed for production site use, DX1 lets you connect devices to existing equipment just by hooking them up with Ethernet cables–no need to install programs specialized for sensors and controllers required for data collection.

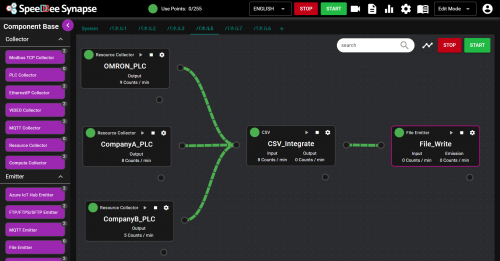

Its user interface enables at-a-glance understanding of data processing flows, allowing you to start using your data in no time. Using this interface, you can intuitively create flows for collecting, analyzing, and sending data, just by connecting on the screen, with lines, the processing blocks that you want to collect or analyze.

(2) From templates to customization: wide-ranging features for wide-ranging scenarios

DX1 is equipped with packages that provide templates for key indicator data used in equipment monitoring, operation status monitoring, factory monitoring, and so forth. Data can be displayed in a tiered structure to suit the needs of a wide range of users, from factory managers to on-site workers, allowing you to drill down from the factory’s production plan targets to equipment operation status.

DX1 can also be customized for your site environment using Python and C, to enable connection with controllers from other manufacturers or for complex calculations, for example.

(3) Zero-downtime implementation

DX1 supports programmable controllers (PLC) from multiple Japanese manufacturers. You can start data collection with your equipment kept running and zero device/software replacement, even if you’re using a non-OMRON PLC. DX1 can also be retrofitted to your equipment, and there’s no need to stop production for data collection.

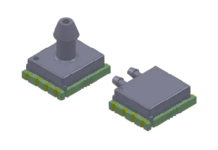

Using the IO-Link master, information devices can be easily connected to each other so that data from different sensors and cameras can be directly retrieved.

OMRON has helped boost productivity on manufacturing sites across the globe, by developing a wide range of control devices and control applications from an on-the-ground perspective. Going forward, we will continue to pursue novel ways of automation to create a future society where sustainable industrial development foundational to excellent healthcare, food, and housing is possible, as well as the prosperity of both humans and the global environment.

For more information visit www.omron.com.