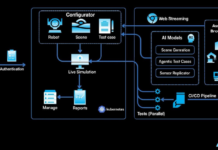

Amtech Electrocircuits, a leading provider of manufacturing solutions, has unveiled significant upgrades to its technology platform, AmtechOS. These enhancements, powered by artificial intelligence, aim to streamline operations and accelerate the transition from prototype to production.

Key Enhancements Include:

- Scope of Work AI: This tool automates the analysis of customer Scope of Work documents, Bills of Materials (BOMs), and CAD files to identify potential issues before quoting begins. It flags missing or ambiguous requirements, mismatches between BOM and CAD data, and highlights possible cost drivers, leading to more accurate and timely quotes.

- Electronics Troubleshooting AI: Now in production, this AI assistant processes inspection data, test results, and repair logs to pinpoint root causes of issues and recommend corrective actions. It predicts failure modes across assemblies, reduces root cause analysis time, and continuously improves through machine learning, resulting in lower rework and higher yields.

- NPI AI: Serving as a virtual Design for Manufacturability (DFM) expert, this tool cross-verifies BOMs, Pick & Place files, and CAD data to ensure alignment before initial builds. It auto-validates reference designators, verifies part placements and orientations, and flags missing or outdated data, ensuring smooth first-pass builds.

All three AI-driven tools are fully integrated into AmtechOS, providing real-time insights throughout the manufacturing process from quoting to shipment. For more information about Amtech Electrocircuits and its agile electronics manufacturing solutions, please visit www.buildamtech.com.