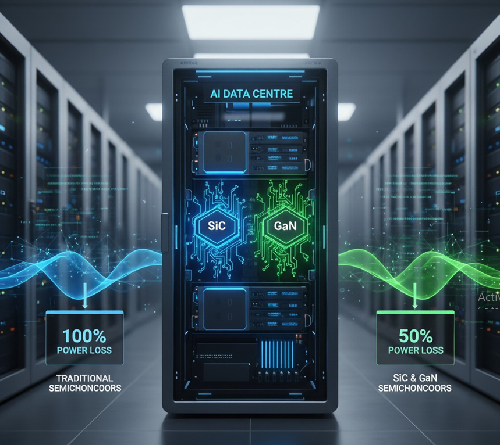

Imagine a world where artificial intelligence powers everything from personalised recommendations to life-saving medical diagnostics, but at a hidden cost: massive energy consumption. AI data centres are guzzling electricity like never before, with power demands skyrocketing to hundreds of megawatts per facility. This surge threatens sustainability and operational costs. Enter silicon carbide (SiC) and gallium nitride (GaN) semiconductors, innovative materials poised to transform how we power these digital giants. By slashing power losses dramatically, often by up to 50% or more in key conversion stages, these technologies promise efficient, scalable solutions for the AI era. Let’s explore how they’re revolutionising data centres, making them greener and more powerful.

The Growing Energy Crisis in AI Data Centres

AI workloads are exploding. From machine learning models to neural networks, data centres now handle computations that require unprecedented power. Traditional systems struggle with inefficiencies, leading to high heat generation and wasted energy. Power supplies in these centres convert electricity multiple times, from grid-level alternating current to the direct current needed by servers. Each step introduces losses, compounding the problem.

In response, new architectures like 800-volt direct current setups are emerging. These designs minimise distribution losses by handling higher voltages with fewer conversion stages. Wide-bandgap semiconductors like SiC and GaN shine here, enabling compact, high- density power systems that keep up with AI’s demands. They support everything from server racks to edge computing, ensuring reliable performance even in challenging environments.

This shift isn’t just technical; it’s essential for sustainability. With AI servers consuming up to 30 times more power than standard ones, efficient power management reduces carbon footprints and operational expenses. SiC and GaN are at the forefront, turning energy-hungry data centres into models of efficiency.

Decoding SiC and GaN: The Power Behind the Efficiency

Silicon carbide and gallium nitride are wide-bandgap semiconductors, meaning they can operate at higher voltages, temperatures, and frequencies than traditional silicon. SiC excels in high-power applications, offering robust thermal management and low switching losses. GaN provides ultra-fast switching and compact designs, ideal for high-density setups.

These materials differ from silicon, which has dominated electronics for decades. Silicon struggles with heat and efficiency at high voltages, leading to larger components and more energy waste. SiC and GaN handle these challenges better, allowing for smaller, cooler- running devices. In data centres, they integrate into power supplies, converters, and switches, optimising energy flow from the grid to the GPU.

For instance, GaN devices use depletion-mode architectures, combining with low-voltage silicon for seamless operation. This setup simplifies integration, making upgrades straightforward. SiC complements this by enabling advanced topologies like interleaved power factor correction, which smooths out energy delivery.

Together, they form a powerful duo, addressing the unique needs of AI infrastructure. Their ability to withstand extreme conditions makes them suitable for modular data centres and renewable energy integrations.

Integrating SiC and GaN into AI Power Architectures

In modern AI data centres, power delivery starts at the grid and ends at the processor. Traditional 48-volt or 54-volt systems fall short for high-density racks, prompting the adoption of 800-volt direct current architectures. Here, SiC and GaN play pivotal roles in every stage.

SiC is often used in front-end AC-to-DC converters, employing topologies like three-level flying capacitor designs. This setup achieves peak efficiencies over 99 per cent, handling high voltages with minimal waste. GaN takes over in DC-to-DC stages, using resonant converters and bidirectional switches for stepping down power to server levels.

These semiconductors enable scalable solutions, from 1-kilowatt to multi-megawatt systems. In AI factories massive facilities with thousands of GPUs, they support direct grid-to-rack power, reducing the need for bulky cables and multiple conversions. GaN’s high-frequency operation shrinks components like transformers, boosting power density to levels like 113 watts per cubic inch.

The result? Data centres that are more resilient and adaptable. They handle fluctuating loads from AI tasks while maintaining stability, even during maintenance. Hot-swap capabilities, powered by SiC, allow server boards to be replaced without shutting down racks, maximising uptime.

Slashing Power Losses: The SiC and GaN Advantage

Power losses in Data centres occur mainly during conversion and distribution. Traditional silicon systems hover at 90 to 94 percent efficiency, meaning 6 to 10 percent of energy is lost as heat. SiC and GaN push efficiencies beyond 98 percent, effectively cutting losses in half or more.

Consider the math: If a silicon converter loses 8 percent of power, a GaN equivalent losing just 2 percent reduces waste by 75 percent. In high-power AI setups, this translates to dramatic savings. SiC reduces conduction and switching losses through its superior thermal properties, while GaN minimises gate charge and capacitance for faster, cleaner operation.

In 800-volt systems, these materials lower current by factors of 16 times compared to low- voltage designs, slashing resistive losses exponentially. Distribution becomes more efficient, with less copper needed and reduced heat buildup. For AI racks drawing hundreds of kilowatts, this means cooler operations and lower cooling costs.

Key benefits include:

- Higher switching frequencies, enabling compact designs without performance drops.

- Lower on-resistance, improving flgures of merit by up to 20 percent over previous generations.

- Enhanced threshold voltages for reliable, low-loss performance under heavy loads.

These improvements aren’t theoretical they’re proven in field usage, with billions of hours accumulated across applications. By targeting losses at every stage, SiC and GaN make AI data centres more sustainable.

SiC and GaN vs. Silicon: Why the Switch Matters

Silicon has been the go-to for power electronics, but it falters in AI’s high-stakes environment. It generates more heat, requires larger cooling systems, and limits voltage handling. SiC and GaN outperform it across the board.

GaN offers faster switching and higher density, ideal for DC converters in server power supplies. Its efficiency gains up to 98.5 percent in resonant stages far exceeding silicon’s capabilities. SiC shines in AC front-ends, achieving over 99 percent efficiency where silicon might top out at 95 percent.

Comparisons show GaN reducing die sizes by 14 percent while cutting on-resistance, leading to smaller footprints and lower costs. Unlike enhancement-mode alternatives, depletion- mode GaN mimics silicon’s ease of use, simplifying designs. SiC adds robustness for high- power rectification, handling temperatures and voltages that silicon can’t.

The switch to these materials cuts system complexity, too. Fewer conversion stages mean less waste, aligning with AI’s need for megawatt-scale scalability. In essence, SiC and GaN aren’t just upgrades they’re necessities for future-proofing data centres.

Real-World Applications: Powering AI from Grid to GPU

SiC and GaN are already transforming AI power supplies. In 12-kilowatt units for data centres, SiC handles AC-to-DC conversion with interleaved topologies, while GaN manages isolated DC-to-DC steps using planar transformers. This combo delivers high density and efficiency, supporting racks from 3 to 12 kilowatts and beyond.

For 800-volt architectures, GaN FETs in 650-volt ratings enable bidirectional switching, simplifying rectifiers and boosting power output. They’re used in totem-pole configurations for evaluation platforms, proving their worth in real scenarios.

Beyond servers, these semiconductors integrate with energy storage and inverters, ensuring stable power during peaks. In edge AI setups, their compact nature fits modular designs, even in remote areas with variable grids. They also support renewable integrations, like solar, for hybrid systems.

The impact extends to maintenance: SiC-enabled hot-swap tech allows safe board replacements on live buses, reducing downtime in mission-critical AI operations. Overall, these applications lower total ownership costs while enhancing reliability.

Driving Sustainability and Scalability in Data Centres

The broader implications of SiC and GaN are profound. By minimising losses, they help data centres meet green targets, reducing emissions equivalent to powering entire cities. Efficiency improvements preserve every watt, crucial as AI racks approach 1 megawatt.

Scalability is another win. These materials support stacking for higher voltages, enabling gigawatt-scale facilities. They align with global standards for low-voltage DC, fostering standardised, expandable infrastructures.

Innovation continues with packages like TOLL and TO-247, offering better thermal paths for high-current paralleling. As AI evolves, SiC and GaN will underpin smarter, more resilient data centres, blending performance with environmental responsibility.

Embracing the SiC and GaN Revolution in AI

SiC and GaN semiconductors are reshaping AI data centres, cutting power losses by up to 50% through superior efficiency and innovative designs. From 800-volt architectures to high- density supplies, they address the energy challenges of tomorrow’s AI world. As demands grow, adopting these technologies isn’t optional it’s essential for sustainable progress. The future of data centres is efficient, powerful, and green, thanks to SiC and GaN.