Metal is not born strong; it’s made that way. From car gears to airplane blades, every part we rely on undergoes periods of high heat and careful cooling. It shapes strength, durability, and performance-all at once. This is the art and science of heat treating.

What is Heat Treating?

Heat treatment alters metals by controlled heating and cooling. It can make soft steel hard enough to cut or turn, and can turn brittle metal into something strong and flexible. The proper combination of temperature, time, and cooling provides each piece with the desired strength and durability. From tools and engines to airplanes, heat treating helps metal perform at its best.

Process Behind Strength

Besides the heat, it takes careful control to make raw metal strong and reliable. Heat treating heats the metal to a set temperature, holds it briefly, then cools it slowly to change its internal structure. Each step affects how the metal behaves, whether it becomes harder, tougher, or more flexible. The process may sound simple, but even a few degrees or seconds can make all the difference. It’s a fine balance of science and skill that gives metal its real strength.

Heat Treating Market Facts

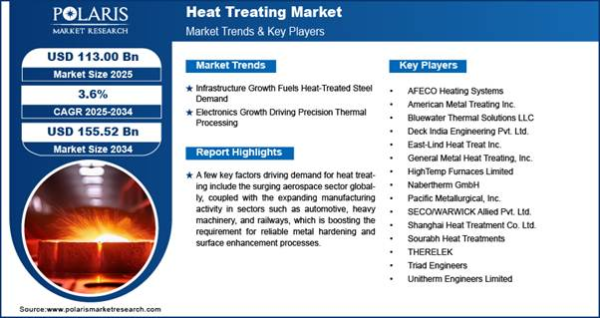

According to Polaris Market Research, the global heat treating market was valued at USD 109.13 billion in 2024 and is expected to grow at a CAGR of 3.6% over the forecast period of 2025-2034. The growth in infrastructure development and the expansion of the electronics and semiconductor sectors are major drivers of this segment.

Types of Heat Treatment

There’s a story behind every metal, and that story is determined by its heat treatment. Each of these processes uses heat and cooling differently to bring out specific qualities in the metal. Here are the more commonly used types:

Annealing

Annealing makes metal easier to work with, both for shaping and machining. In this process, the metal is gradually heated and cooled at a controlled rate, usually in a furnace. This relieves internal stresses and improves ductility by refining the grain structure. The result is a softer, more workable material that won’t crack or break during forming or cutting.

Quenching

Quenching is the process that gives toughness to the metal. The metal is heated to a high temperature and then quickly cooled, often in oil, water, or air. The sudden change of condition fixes its structure in a hard state, thereby increasing strength and wear resistance. Quenching renders the metal brittle; thus, this is normally followed by tempering to achieve a good balance.

Tempering

Tempering is performed after quenching to relieve brittleness and enhance toughness. The already-quenched metal is heated to a moderate temperature and cooled again. Such controlled reheating can help dissipate internal stresses and improve the balance of strength, hardness, and flexibility, making it ideal for tools, gears, and machine parts.

Normalizing

Normalizing homogenizes the metal’s internal structure. In this, the metal is heated to a temperature slightly above the critical temperature and then cooled in the air. This heat treatment refines grain size, which may improve strength and toughness. This is quite common among steel parts used for general applications that require uniform properties and enhanced machinability.

Case Hardening

Case hardening is a process by which the surface of a part attains high hardness, while the core remains soft and tough. Carburizing and nitriding are treatments that involve diffusing carbon or nitrogen into the surface of a metal and heating it. This hardens the shell and gives it resistance to wear by friction and impact. This is useful in gears, shafts, and bearings.

How is Technology Shaping Heat Treating?

Modern heat treatment is not about furnaces and timing; it’s about technology and innovation. Advanced sensors, automation, and computer controls maintain tight temperature control and cooling rates with minimal error, thereby enabling consistent output. Modern techniques, including vacuum heat treating, induction heating, and better furnaces, cut processing time and reduce environmental impact. Digital monitoring enables manufacturers to adjust each batch for exactly the right strength and performance. Technology is turning heat treating from an artisanal craft into a precise, high-tech process.

Summing Up

Heat treating quietly powers the modern world, turning ordinary metals into the strong, precise parts in everything from cars and planes to medical equipment and microelectronics. Skill, science, and innovation are at the forefront, enabled by new technologies and changing market demands. Heat treating ensures metals perform at their best, inside and out.

For more information, visit https://www.polarismarketresearch.com/industry-analysis/heat-treating-market