News highlights:

- Texas Instruments opened its second state-of-the-art assembly and test factory in Melaka, Malaysia, that will assemble and test billions of chips annually, strengthening the company’s global supply chain.

- With a potential investment of up to MYR 5 billion over time, this new factory – which is in production – will support up to 500 local jobs when fully operational.

- This expansion furthers TI’s commitment to controlling its manufacturing operations and processes to deliver the dependable capacity its customers demand.

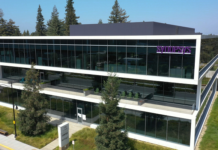

Texas Instruments (TI), a global semiconductor company that designs, manufactures, and sells analog and embedded processing chips, announced the opening of its newest state-of-the-art assembly and test factory in Melaka, Malaysia, TIEM2. This new factory features advanced factory automation to bump, probe, assemble and test billions of analog and embedded chips annually that are vital for nearly every type of electronic system – from vehicles to smartphones to data centers.

TI’s new six-level factory in Melaka – which is in production – spans more than 900,000 square feet and connects to TI’s existing Melaka assembly and test factory. The combined facilities now encompass more than 1.4 million square feet of manufacturing space to transform processed semiconductor wafers into finished chips.

TI’s Melaka expansion, representing a potential investment of up to MYR 5 billion, will be equipped over time to align with demand for the company’s analog and embedded processing chips. The factory will also support up to 500 local jobs when fully operational. This investment in Melaka advances TI’s plans to bring 90% of its assembly and test operations internal by 2030, strengthening the company’s internal manufacturing operations by owning and controlling its supply chain.

Celebrating a manufacturing milestone for Malaysia

To celebrate the official opening of its new factory, TI hosted Datuk Seri Utama Ab Rauf Yusoh, chief minister of Melaka, along with other local dignitaries, for a tour of the site.

“Texas Instruments’ investment in Melaka is a strong endorsement of our state’s potential,” said Datuk Seri Utama Ab Rauf Yusoh, chief minister of Melaka. “When fully operational, this facility will generate hundreds of new high-quality jobs for our people and contribute to Melaka’s industrial growth, strengthening our position as a key player in Malaysia’s economic and technological progress.”

TI has a long history of owned, regionally diverse internal manufacturing operations. The company has 15 manufacturing sites worldwide, including wafer fabs, assembly and test factories, and bump and probe facilities. Integrating two state-of-the-art assembly and test factories in Melaka, combined with TI’s established operations in Kuala Lumpur, allows the company to maximize operational efficiencies and scale to better support its customers around the world.

“For more than 50 years, TI has built its presence in Malaysia, and this new factory underscores the talent and expertise of our team here,” said Subbah Rao, vice president and country managing director for Texas Instruments Malaysia. “Our new Melaka expansion strengthens our internal manufacturing capabilities, enabling us to reliably deliver products to our customers when and where they need them.”

Operating in Malaysia for more than 50 years

Since opening its first factory in Selangor in 1972, TI has grown alongside Malaysia for more than half a century. Today, TI has back-end manufacturing operations in both Melaka and Kuala Lumpur. The back-end manufacturing process is a key part of TI’s internal manufacturing operations and undergoes continuous expansion, modernization and automation to support customer demand.

TIEM2 was designed to achieve Leadership in Energy and Environmental Design (LEED) Gold certification, one of the building rating system’s highest levels of structural efficiency and sustainability.

Advanced equipment in the factory reduces waste, water and energy consumption per chip, demonstrating TI’s commitment to responsible, sustainable manufacturing.

For more information visit www.ti.com.