From satellites that keep communications running to rovers that explore distant planets, robots play an integral role in understanding and interacting with space. But withstanding the rigors of space is no small feat. Robots must endure harsh conditions, such as extreme temperatures, intense radiation, and unpredictable terrain. To do so, they rely on cutting-edge materials and technologies designed to protect and maintain their functionality in the most unforgiving environments.

The Hostile Environments of Space and Planetary Surfaces

Space robots are subjected to harsh conditions, whether they are exploring planetary surfaces or traveling through the vastness of space.

Planetary Hazards

On planetary surfaces, like that of Mars, space robots face environmental stressors, including dust storms that can obscure sensors and damage moving parts, jagged terrain, and the constant threat of mechanical damage from rocks and debris. Additionally, solar flares can strike without warning, exposing sensitive electronics to bursts of radiation. While conditions on planetary surfaces are severe, they pale in comparison to the extremes encountered in space.

Space-Based Extremes

Satellites and robotic spacecraft orbiting Earth or traveling deeper into space must contend with harsh temperatures and extreme temperature fluctuations. For example, the International Space Station (ISS) can undergo 16 thermal changes in a 24-hour period while orbiting the Earth. During orbit, the external temperature of the ISS can range from more than 100°C in direct sunlight to -100°C in the shadow of Earth. Experiencing temperature fluctuations causes materials to expand and contract repeatedly, which threatens structural integrity. For large structures like the ISS, managing volume changes over a widespread area is easier. However, for smaller robotic systems, such changes can be difficult to manage, which is why advanced thermal solutions are one of the most important defenses for space robots.

Radiation is another major concern. Space robots are bombarded by atomic oxygen, ultraviolet (UV) rays, high-energy protons and electrons, and cosmic rays. Satellites—especially those in the Van Allen radiation belts—are particularly vulnerable to solar activity. Sudden solar flares can dramatically spike radiation levels, posing a threat to onboard electronics and sensors.

Mechanical stress is also a constant threat to satellites and other robotic spacecraft. Space debris, micrometeorites, launch vibrations, and acoustic pressures can all damage robotic systems. To survive, these robots must be constructed with materials that are resilient at a structural and material level to withstand the extreme mechanical stress of space.

Advanced Material Protection for Space Robotics

To withstand the harsh conditions of space, robots are constructed using advanced materials that offer exceptional durability, thermal resistance, and radiation shielding. While no solution is 100 percent effective, these materials provide an effective structural barrier that enables many space robots to function for long time periods in space.

Refractory Metals: Built for Extreme Heat

Refractory metals are metal alloys with extremely high melting points and exceptional strength. Constructed using tungsten, titanium, tantalum, niobium, and nickel, these alloys boast melting points above 3400°C and Vickers hardness ratings up to 4000MPa. Refractory metals’ resistance to corrosion and mechanical stress makes them ideal for structural components, actuators, gears, and even propulsion systems.

Depending on the space application, the weight of refractory metals can be an issue. In these cases, engineers can combine refractory metals with carbon fiber to create lighter composites. Additionally, recent advances in additive manufacturing have enabled designers to fabricate complex, optimized geometries from these metals, improving both the tailoring to the intended structural function and weight efficiency.

Ceramic Materials: The Silent Protectors

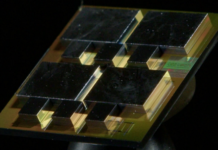

Ceramic materials, particularly ultra-high temperature ceramics (UHTCs), are a cornerstone of space robot design. Composed of carbides, nitrides, and borides of transition metals like hafnium and zirconium, UHTCs offervery high hardness, excellent mechanical properties, and a low friction coefficient. UHTCs can resist UV and high-energy particle radiation, extreme temperatures, corrosion, ablation, and even micrometeoroid impacts, making them indispensable for long-term missions.

Ceramic materials can be used to create robotic components, particularly when employed in structural or load-bearing elements, or as a coating to enhance barrier properties. Ceramics are often found in space robots’ arms, bearings, gears, and heat shields.

Graphene: A Smart Solution for Thermal Control

In addition to advanced material coatings such as refractory metals and ceramics, one of the most widely used methods for shielding robots and spacecraft from the harsh thermal conditions of space is multi-layer insulation (MLI) blankets. MLI blankets have been a staple in spacecraft design for decades, leveraging layers of electrically conductive and optically reflective materials to manage temperature. But new technologies are pushing the boundaries of what is possible in thermal management.

Smarter options are now emerging for low Earth orbit (LEO) satellites that are subject to extreme thermal changes throughout the day. SmartIR, a UK-based startup, has developed a graphene-based thermal management system called the Variable Emissive Radiator (VER). Unlike conventional systems that rely on conductivity, VER uses emissivity to control heat flow. Each panel can modulate infrared and visible light independently, allowing for localized temperature control across a spacecraft’s surface. Tested across a temperature range of -120°C to +120°C, VER panels have reduced satellite weight by 10 percent and power consumption by 40 percent.

Innovations such as VER illustrate that the excellent thermal, electric, and optical properties exhibited by graphene materials could soon help usher in a new revolution of smart thermal protection systems for a range of space applications.

Navigating Harsh Planetary Terrain

Rovers exploring planetary surfaces must constantly contend with dust, radiation, and unstable terrain. To withstand these challenges, they rely on sophisticated imaging and sensing technologies. Some sensors detect dust and sand that might obscure cameras and other optical sensors, while others check the rover’s overall health to ensure it is running as intended. Radiation-hardened integrated circuits (ICs) and redundant systems help mitigate unexpected radiation spikes caused by solar flares.

Cameras on rovers play an essential role in navigating rugged, planetary terrain. Rovers have two main cameras for overcoming potential adversity: hazard avoidance cameras (Hazcams) and navigation cameras (Navcams). These cameras are critical components of a rover’s autonomous navigation system. Hazcams detect potential obstacles—such as sand dunes, trenches, and rocks—in front of and behind the rover. The 3D view provided by Hazcams enables rovers to take necessary evasive action and autonomously decide the safest path through the terrain. When a rover navigates autonomously, the Navcams serve as eyes for engineers monitoring the mission. These cameras can detect small objects from a distance and, alongside Hazcams, help to secure a safe path before navigating the terrain after an engineer’s command to move to a certain location.

Conclusion

Space robots must survive some of the harshest conditions. Whether orbiting Earth or exploring distant planets, robots operating in space rely on advanced materials and technologies to endure extreme temperatures, radiation, and mechanical stress.

As space exploration continues to evolve, so does the need for more resilient and intelligent robotic systems. Innovations such as graphene-based thermal management and ultra-high-temperature ceramics are paving the way for longer, more ambitious missions. With each advancement, engineers move closer to unlocking the full potential of robotics in space—and deepening our understanding of the universe.

Source: Mouser blog