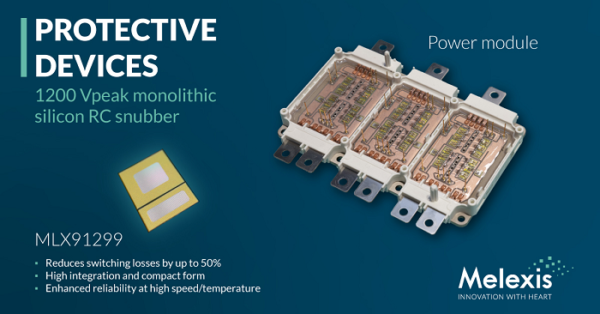

Melexis announces the MLX91299, a novel silicon-based RC snubber designed to enhance the performance of silicon carbide (SiC) power modules. Built on the company’s motor control and current sensing expertise, it supports automotive and industrial high-voltage power applications. The snubber helps engineers mitigate voltage spikes and oscillations to improve system reliability and efficiency.

The growing adoption of SiC power modules in automotive and industrial applications reflects the increasing demand for high-efficiency, high-voltage power modules. Operating at fast switching speeds and elevated voltages, SiC devices are inherently susceptible to voltage transients, high-frequency oscillations, and parasitic effects. These issues risk generating motor load leakage currents, localized heating, and electrical stress that severely impact module reliability and system efficiency. Integrating an RC snubber mitigates these effects, and early measurements from Melexis show the RC snubber can reduce switching losses by up to 50%. This supports improved system efficiency, optimized power density, better thermal management, and reduced Bill of Materials (BOM) cost.

Melexis’ RC snubber is a silicon-based protective device integrating both a resistor and a capacitor, providing high-voltage transient protection in a compact form. Designed for seamless assembly within high-voltage power modules, it follows standard integration approaches compatible with SiC devices. Its material and form factor enable precise integration with existing power module layouts, improving manufacturability, reducing assembly complexity, and ensuring consistent performance across devices.

Functionally, the RC snubber mitigates high-speed effects inherent to wide-bandgap semiconductors, including voltage transients and parasitic oscillations, while improving electromagnetic compatibility (EMC). This prevents localized voltage overshoots that could stress the SiC devices, enabling long-term reliability at higher switching frequencies. Its compact integration within power modules, featuring backside metallization compatible with sintering and soldering processes, allows it to leverage the same thermal dissipation channels as SiC components, minimizing hotspots and maintaining consistent module performance even at SiC junction temperatures up to 200 °C.

With a breakdown voltage of >1500 V, it is suitable for traction inverters, onboard chargers, DCDC converters, and other high-voltage automotive and industrial applications. Its design can reduce cooling and material requirements by lowering heat dissipation for a given power output, or alternatively allow higher power density and optimize transistor count within the same thermal budget, maintaining reliable electrical and thermal performance.

“Our silicon-based RC snubber is the ideal solution for protecting and enhancing SiC power modules. By addressing voltage spikes, ringing, and thermal challenges at the system level, we give designers the freedom to innovate, optimize performance, and reduce costs,” said Billy Ye, Product Line Director at Melexis. “While the MLX91299 is an exciting first step, it is just the start for our new Protective Device family, which will continue to expand to meet the evolving needs of power modules and emerging power applications.”

The MLX91299 is the first device in Melexis’ Protective Device family and has already undergone early validation with select customers. Samples are available now for evaluation. The family will expand to support a wide range of high-voltage applications. For more information, please visit melexis.com/MLX91299.