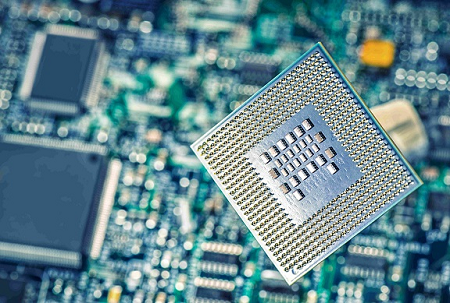

Introduction: Phones, cars, laptops, TVs—everything we use in our daily lives—all rely on semiconductor chips. For many years, India had to import almost all semiconductor chips from other countries, but now India is building its own chip factories. This process may be slow, but its direction is very clear: India has to become self-reliant in chip manufacturing.

Why India Is Investing in Chip Manufacturing?

1. Rising Demand Inside India

Industries like electric vehicles, telecom, 5G towers, AI devices, smart appliances — everyone needs chips. And demand keeps rising every year.

2. The Global Chip Shortage

During the worldwide chip shortage, Indian companies suffered. Cars couldn’t be delivered, electronics got delayed, and it became obvious that depending fully on imports is risky.

3. Government Support

To solve this problem, the government started the Semicon India program, which gives financial support to companies building chip plants.

Major Chip Plants Being Built in India

1. Tata Semiconductor Fab – Dholera, Gujarat

This is currently India’s most important and ambitious chip project.

- Tata is setting up a large fabrication plant

- If everything stays on track, the first chip may be ready by 2026

- Plant will produce 28nm–55nm chips

- These chips are used in EVs, telecom equipment, defence electronics, industrial machines, etc.

This one project alone can reduce a huge part of India’s import dependency.

2. Tata ATMP / OSAT Plant – Assam

This plant is not for making chips from scratch but for packaging and testing them.

- Think of it like the finishing and checking stage

- Important step before a chip is used in real devices

- Easier to set up than a full fab, but still crucial for the ecosystem

This plant will create thousands of skilled jobs in the region.

3. Micron Semiconductor Plant – Sanand, Gujarat

Micron, a well-known US company, is building a large unit in Sanand.

- The facility focuses on memory chip assembly and testing

- Memory chips are used in laptops, servers, and many electronics

- The plant includes high-grade cleanrooms and advanced equipment

This project is expected to boost India’s presence in the global memory-chip market.

Why These Chip Plants Matter

Reduced Imports

India currently imports almost 90% of its chips.

With these plants, this number will slowly start dropping.

More Jobs & Skill Growth

Semiconductors need highly trained workers.

Thousands of jobs will open in:

- Engineering

- Chip designing

- Packaging & testing

- Equipment handling

- Cleanroom operations

Faster Growth for Indian Industries

When chips are made locally, industries like EVs, 5G, AI devices, and consumer electronics grow much faster.

India Can Join the Global Supply Chain

The world is looking for alternatives to China and Taiwan.

India has a real opportunity to become part of the global chip supply chain.

Will India Become a Chip Hub?

This is a big dream, so it will take time and Semiconductor manufacturing is one of the hardest industries in the world.

Factories take years to build, billions of dollars to investment, and require highly skilled workers to operate.

But the good news is:

- The land is ready

- The funding is approved

- Construction is happening

- Big companies are interested

- Government is pushing continuously