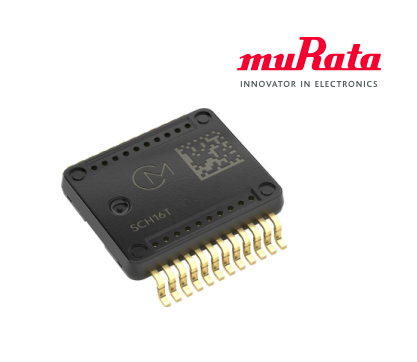

Murata Manufacturing Co., Ltd. has announced the expansion of its SCH16T series of high-performance inertial measurement units (IMUs) with the introduction of the SCH16T-K20, targeting industrial, prosumer, and consumer markets worldwide. Designed for OEMs in robotics, drones, and camera systems, as well as IMU module manufacturers and system integrators requiring safety-critical IMUs, the SCH16T-K20 delivers market-leading precision, mechanical robustness, and reliability.

In demanding inertial measurement applications such as dead-reckoning navigation as well as drone and camera stabilization, small measurement errors can accumulate over time leading to unpredictable measurement results. In these applications, key IMU parameters such as noise density, offset bias drift, and vibration rectification ultimately limit the end-application performance and achievable response speed. Murata improves all the key areas with the new SCH16T-K20, which features a brand-new MEMS accelerometer and improved gyroscope temperature calibration.

The SCH16T-K20 is a 6 axis IMU with a typical gyroscope noise density of 0.0004 (°/s)/√Hz, gyroscope bias instability of 0.3 °/h, and accelerometer noise density as low as 33 µg/√Hz. Like all other SCH16T products, the SCH16T-K20 has a wide operating temperature range from -40 °C to +110 °C, a supply voltage of 3.0–3.6 V, and I/O voltage of 1.7–3.6 V, and a compact size of 0.46 × 0.53 × 0.11 inch (11.8 × 13.4 × 2.9 mm).

The driver behind the SCH16T-K20 accelerometer performance improvement is the brand-new accelerometer MEMS based on Murata’s proven 3D MEMS technology. The new MEMS uses a double-differential measurement principle, familiar from current SCA3400 and legacy SCA103T series sensors. The double differential measurement enables SCH16T-K20’s market leading low noise density, as well as thermal and lifetime stability.

The SCH16T-K20 also includes an enhanced version of the market-leading low-noise SCH16T gyroscope, now tuned specifically for the -40 °C to +85 °C temperature range to enable low offset bias shift across that range. All SCH16T series products are carefully validated with a test set based on AEC-Q100 operating temperature Grade 1 (-40 °C to +125 °C) standards, ensuring reliable operation over a wide temperature window. The series sensors include market-leading self-diagnostic features, making them suitable for safety-critical applications. Murata’s unique MEMS stands out in the competitive IMU market for its exceptional mechanical resilience to shocks and vibration rectification. The series’ robust design and reliability contribute to longer device lifespans and reduced waste.

The SCH16T-K20 becomes the highest-performing variant in the SCH16T lineup while maintaining pin-to-pin and software compatibility. This compatibility makes integration of different SCH16T variants easy for OEMs and module designers. Mass production of the SCH16T-K20 is scheduled to begin in the first half of 2026. Murata will continue developing sensor solutions aligned with evolving market demands, contributing to safer, more sustainable, and higher-performing technologies across industrial and consumer markets.

For more details on this product, please visit here.