Seica’s technology strategy is focused on the potential of artificial intelligence as a key factor for smarter, faster, and more efficient electronic testing solutions.

At the core of this vision is the VIVA software platform, which provides intelligent integration across all stages of the customer’s manufacturing process. VIVA seamlessly connects data collection, traceability, MES interaction, and repair operations into a unified digital ecosystem, transforming test systems from standalone tools into fully connected, data-driven assets.

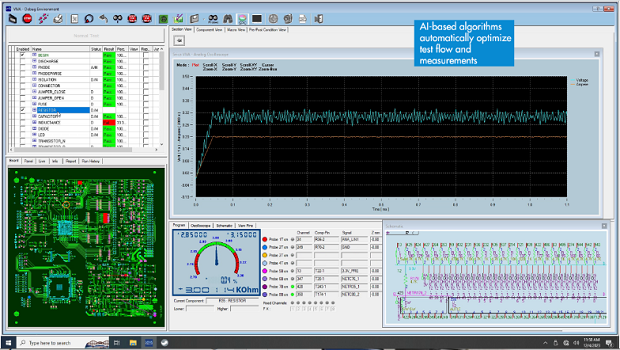

Artificial Intelligence plays a critical role within the VIVA platform. Advanced AI algorithms are leveraged to enhance fault detection during electronic board and module testing, improving the ability to identify complex or intermittent failures that traditional rule-based approaches may overlook. By continuously analyzing large volumes of test data, VIVA can recognize patterns, correlations, and anomalies, enabling more accurate diagnostics and faster root-cause analysis. In addition, AI-based decision support assists engineers by suggesting advanced technical solutions during debug and repair phases, significantly increasing diagnostic accuracy while reducing downtime and operator dependency.

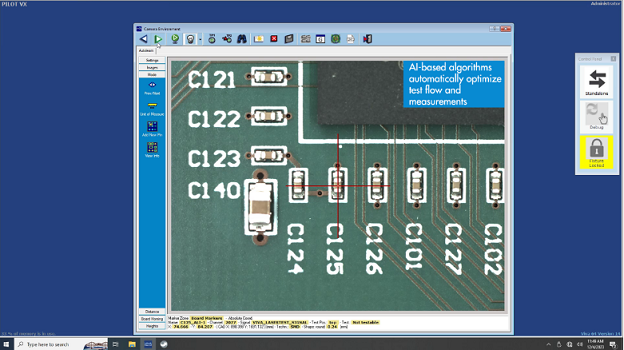

AI is also used to optimize test efficiency in real time. Through smart analysis and adaptive learning, VIVA can dynamically optimize test sequences, parallelize different types of measurements, and automatically adjust test flows based on board complexity, historical results, and production conditions. This results in shorter test times, improved throughput, and higher overall equipment effectiveness, particularly in high-mix and fast-changing manufacturing environments.

The mil-aero sector has been a strategic focus for Seica throughout 2025 and will remain so in the coming years. In 2026, Seica will introduce the new S20 line of test solutions designed for the latest-generation power semiconductors. These solutions combine Seica’s 40 years of expertise in electrical test with AI-enhanced analytics to deliver flexible, scalable, and high-performance systems capable of meeting the stringent reliability and traceability requirements of aerospace and defense applications.

Automation and AI converge in Seica’s flagship platforms, such as the Pilot VX flying probe system. Fully automated and powered by state-of-the-art mechanical architecture, the Pilot VX benefits from AI-driven test optimization that can reduce test time by up to 50%. Machine learning models analyze probing strategies, measurement sequences, and historical outcomes to maximize speed and coverage without compromising accuracy. AI-enhanced sensor fusion, combining visible and infrared imaging with advanced electrical measurements, further extends diagnostic capabilities, especially in high-frequency and high-power applications.

Similarly, Seica’s Valid family of in-circuit and functional test systems integrates AI-enabled software management to support high-volume, automated production lines. The latest versions of the VIVA platform introduce intelligent operator interfaces and predictive maintenance features, using AI to anticipate failures, optimize resource usage, and simplify system operation.

Looking ahead to 2026, Seica’s business outlook is strongly positive, supported by increased presales activity and continuous investment. Through close collaboration with customers and decades of test expertise, Seica continues to position itself as a leader in smart innovation, delivering AI-powered, high-performance test solutions ready for the challenges of next-generation electronics manufacturing.

For more information, visit www.seica.com.