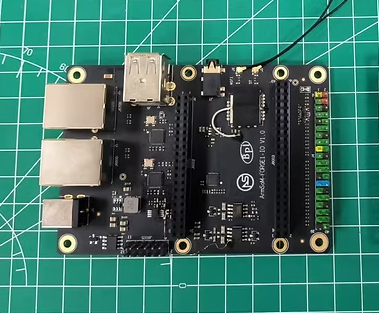

ArmSoM RK3506J CM1:

Amidst the wave of industrial automation, a core board half the size of a credit card is quietly how-we-designed-the-armsom-cm1-redefining-the-modular-revolution-in-industrial-grade-embedded-systetransforming traditional industrial control development paradigms. The ArmSoM CM1, with its innovative modular design and robust industrial performance, delivers a groundbreaking solution for edge computing and industrial control applications.

1. ArmSoM CM1 Design Philosophy & Industrial Positioning

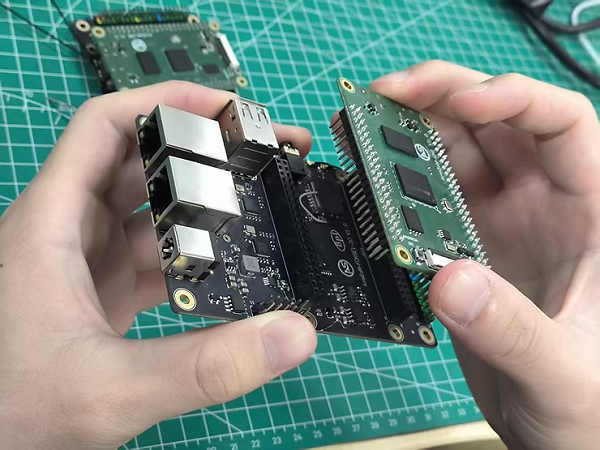

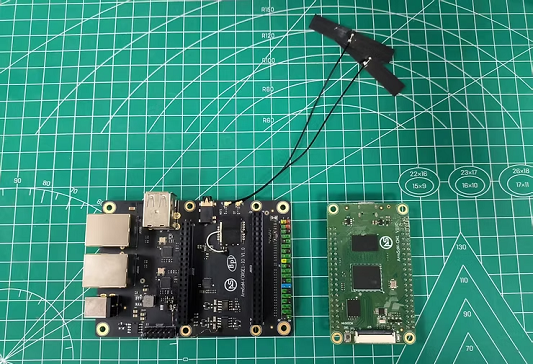

Born from deep insights into industrial pain points—rigid interfaces, upgrade difficulties, and prolonged development cycles—the CM1 adopts a “core-carrier board” separation architecture. This physically decouples the computing core (CM1 module) from interface expansion units (carrier board), empowering manufacturers to flexibly adapt to evolving field requirements.

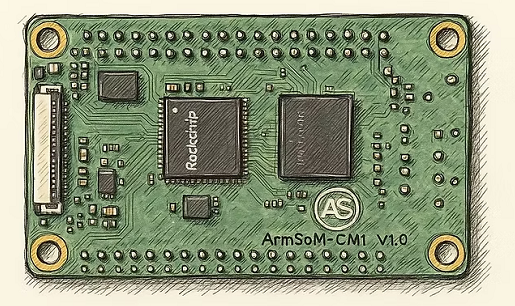

Standardized Core:

Integrating RK3506J processor, 2GB DDR3L RAM, and 8GB eMMC storage in a 55×40mm footprint, the CM1 delivers full computer functionality. This compact design eliminates the need to redesign core circuits, slashing R&D cycles.

Customizable Interfaces:

Gold-finger connectors provide DSMC (Localbus), FLEXBUS, dual 100M Ethernet, USB 2.0, CAN, and I2C signals, enabling scenario-specific carrier board designs. Identical CM1 cores can power oil rig control systems and smart factory robots through different interface configurations.

Industrial Reliability:

Rigorously tested for stable operation at -40°C to 85°C, the CM1 maintains performance in Arctic substations or equatorial factories, meeting stringent industrial demands.

2. Technical Architecture: Engineered for Industrial Scenarios

2.1 Heterogeneous Core Synergy System

The RK3506J’s innovative architecture delivers unique advantages:

- 3×Cortex-A7 Cluster (1.5GHz): Handles Linux scheduling and 1080p@60fps HMI rendering

- Cortex-M0 Real-time Core: Enables ≤1ms deterministic control for PLC/motor tasks

This hybrid architecture optimally separates control and computation. The A7 cores manage GUIs and complex algorithms, while the M0 cores control robotic arms or collect sensor data concurrently without interference. In smart factories, CM1 can operate touch interfaces and CAN devices via MIPI/DSI and CAN without extra PLC modules.

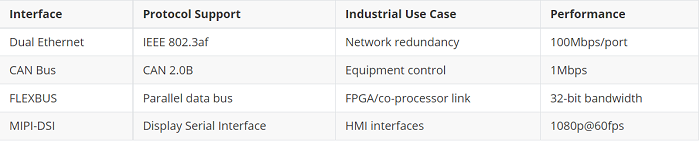

2.2 Industrial-Grade Interface Cluster

The CM1’s interface design addresses key industrial challenges:

- Dual Ethernet Redundancy: Supports ring topology, automatically switching to a backup link within 50ms if a connection fails, ensuring continuous network operation.

- Native Industrial Bus: Integrates a CAN2.0B controller supporting Modbus/CANopen protocols for direct connection to industrial devices like inverters and servo drives.

- Expansion Capability: Expandable via FLEXBUS+DSMC bus for FPGAs or dedicated control chips, enhancing computing power for motion control and machine vision applications.

2.3 Modular Architecture Design

The mechanical and electrical design of CM1 fully considers industrial needs:

- BTB Connector + Screw Lock: The design features BTB connectors and a combination of copper standoffs and lock screws, ensuring a robust connection between the core board and baseboard even in high-vibration environments. It has been tested to withstand 50G shock and vibration without failure.

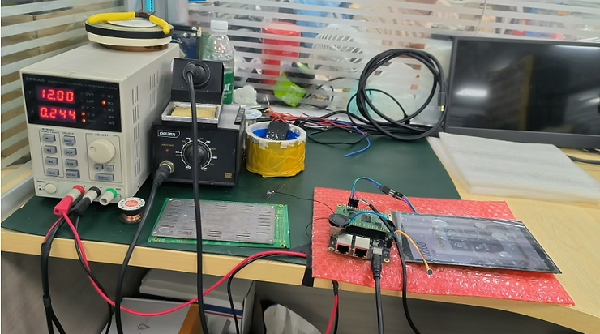

- Dual Power Inputs: The device supports both Type-C (DC 5V) and DC jack (DC 12V) power inputs, allowing for flexible switching. This meets the dual power supply needs when the core board is used with a baseboard and also satisfies the power and programming requirements when the core board is used standalone, offering convenience and versatility.

- Power Protection: The power input includes overvoltage protection, overcurrent protection, reverse polarity protection, ESD protection, and redundant dual MOSFET design, suitable for most industrial applications.

Case study: An industrial customer upgraded an old PLC system using CM1, retaining existing CAN bus devices and only developing a custom carrier board. When processor upgrades are needed, the core board can be replaced directly, with the carrier board reusable, reducing costs by 60%.

3. Application Scenarios: Smart Transformation from Factory to Edge

3.1 Legacy Equipment Modernization

Challenge: Old industrial equipment faces the dilemma of discontinued chips and outdated interfaces, with high costs associated with complete system replacement.

Solution: By customizing a carrier board to interface with the equipment’s native interfaces, and utilizing CM1’s Linux system + RTOS technology, intelligent upgrades can be achieved. Case study: A textile machinery factory upgraded the control system of looms imported in the 1990s to a predictive maintenance system. By analyzing vibration data in real-time with CM1, they were able to provide early warnings of bearing failures.

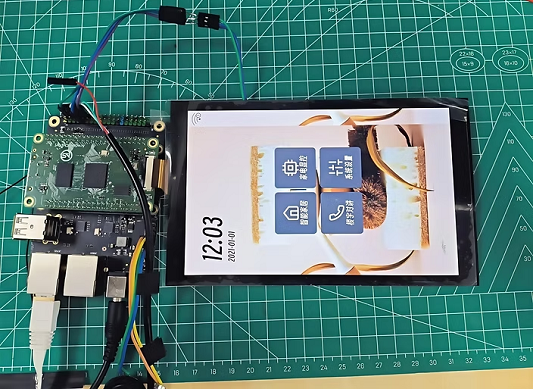

3.2 Cross-Scenario Industrial HMI

The display capabilities of the CM1 make it an ideal platform for Human-Machine Interfaces (HMIs):

- Dual Independent Displays: Simultaneously drives control screens and data dashboards via MIPI+DSI interfaces.

- -40°C Cold Start: Under -40℃ environmental testing, the cold start time is ≤8 seconds, significantly better than the over 1 minute start time of traditional industrial PCs.

- Unified Management: Supports a Web-based HMI framework, allowing remote monitoring from phones/computers.

4. Developer Ecosystem: Full-Stack Support

4.1 Hardware/Software Toolkit

Open-Source Designs:

- GitHub reference designs (4-layer) with:

- Industrial EMC guidelines

- CAN bus protection circuits

Dev Kit:

- Core board + evaluation carrier (dual GbE, RS-485, CAN)

Optimized BSP:

- Preempt-RT patched Linux (≤100μs latency)

- Built-in Modbus/CANopen/Profinet stacks

- Diagnostic tools (memory/watchdog monitoring)

4.2 Global Support Network

- 12-hour technical response

- 10-year RK3506J supply guarantee

- Educational partnerships :

- Embedded Linux development textbooks

5. Conclusion: Modularizing Industrial Evolution

The ArmSoM CM1 is not only a high-performance core module but also represents the future of industrial embedded systems—modular, evolvable, and scenario-adaptive. By standardizing the core computing unit and opening up interface customization, the CM1 resolves the contradiction between “long-term supply stability” and “rapid technological iteration” in the Industry 4.0 era.

Its modular design appeals to high-end users, proving modularity as key to differentiated competition. The ArmSoM CM1 brings this concept to the industrial field, building a more valuable modular ecosystem through open-source carrier board designs and heterogeneous computing architectures.

Looking ahead, ArmSoM will continue to deepen two directions: refining the “core module + functional modules” ecosystem (e.g., expanding AI acceleration modules, 5G communication modules) and fostering a developer community, driving innovation through open-source hardware contests and industrial application libraries.

Enabling every industrial device with an evolvable “heart” is the core mission of the ArmSoM CM1 modular revolution.