Uncrewed aerial vehicles (UAVs) have progressed well beyond hobbyist platforms, now serving in mission-critical roles across sectors such as precision agriculture, infrastructure inspection, cinematography, emergency response, and defence. As onboard system complexity increases, the demand for accurate, closed-loop control of payload mechanisms has become essential. Applications like gimbal stabilisation and controlled fluid dispensing rely heavily on precise motion feedback to maintain performance under dynamic flight conditions. Central to these control systems is the rotary encoder—a sensor that converts the mechanical shaft position into reliable electrical signals for system feedback. The AMT series encoders from Same Sky offer a compelling solution, delivering high-resolution output with robust environmental resistance, low power consumption, and simplified digital configuration. Their mechanical flexibility and immunity to contaminants make them well-suited for UAV payload integration where weight, reliability, and precision are paramount.

Payload Motion Control Challenges in UAV Systems

Designing motion control subsystems for UAV payloads introduces a host of engineering constraints due to the platform’s operational and physical limitations. Engineers must account for several factors that directly impact system performance and flight viability:

- Environmental Resilience: UAVs deployed in agriculture, defence, and inspection sectors operate in harsh outdoor conditions. Payload components must withstand particulate ingress (dust, debris), moisture exposure, and wide ambient temperature variations. Additionally, continuous exposure to multi-axis vibration—both from aerodynamic forces and rotor-induced harmonics—places strict demands on component durability and mechanical stability.

- Power Efficiency: Given the limited onboard energy budget, all electronic subsystems, including encoders and motor drivers, must exhibit minimal power draw. Efficiency directly correlates with extended flight duration and increased mission capacity.

- Mechanical Footprint: Payload components must be optimised for both mass and volume. Excess weight reduces thrust-to-weight ratio, limiting flight time and manoeuvrability. Therefore, engineers must specify components that achieve the desired functional performance within tight spatial and mass constraints.

- Precision and Reliability: For payloads involved in functions like orthomosaic mapping, precision spraying, or LIDAR scanning, encoder resolution and signal integrity are critical. Any deviation in position or velocity feedback can result in system-level error propagation, degrading overall mission outcomes.

To address these challenges, UAV payload designers must select motion feedback solutions, such as rotary encoders, that combine high signal fidelity, rugged environmental tolerance, compact packaging, and energy-efficient operation. The performance envelope of these encoders often dictates the payload system’s precision, repeatability, and stability.

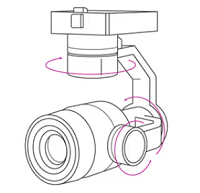

Gimbals

Gimbals function as electromechanical stabilisation systems, enabling precise orientation control of payloads—typically imaging devices—across multiple rotational axes. In UAV applications, gimbals are essential for maintaining a stable visual frame or sensor alignment regardless of the drone’s dynamic motion profile. These systems are commonly used to support high-resolution cameras for aerial videography, thermal imaging, surveillance, and mapping applications.

The control architecture of a gimbal relies on real-time closed-loop feedback to actively counteract pitch, roll, and yaw disturbances. At the core of this feedback loop are rotary encoders, which provide accurate angular position data to the system’s motor controllers. The fidelity and latency of this feedback directly influence system responsiveness, jitter compensation, and image stability.

Same Sky’s AMT series encoders are well-suited for UAV gimbal integration due to their high-resolution digital output, low power consumption, and programmable resolution. Engineers can dynamically tailor the encoder’s output granularity to the specific responsiveness requirements of the application, whether optimising for rapid orientation adjustments in high-speed tracking scenarios or achieving ultra-smooth motion in cinematic use cases. This tunable resolution capability precisely matches encoder performance with the gimbal’s mechanical and control system characteristics, ultimately improving payload functionality and mission effectiveness.

Agricultural Dispense Systems

Agricultural drones are advancing precision farming by enabling targeted delivery of fertilisers, pesticides, and seeds. To achieve optimal coverage and resource efficiency, these UAV payload systems must maintain tight control over dispensing variables such as timing, flow rate, and rotational speed. Key motion-controlled elements include:

- Hatch Actuation: Accurate angular feedback ensures timed and proportional opening/closing of payload release hatches.

- Pump Regulation: Real-time monitoring of motor shaft position allows precise flow control for liquid dispersion.

- Rotating Sprayers: Encoder feedback governs rotational velocity to maintain uniform coverage across variable flight speeds and terrain.

By integrating high-resolution AMT encoders, design engineers can implement adaptive control loops, potentially augmented with AI, that respond dynamically to environmental inputs such as wind speed, elevation, and ground texture. These closed-loop systems reduce material waste, increase field uniformity, and improve overall operational efficiency, which are key metrics in precision agriculture applications.

Optimised for UAV Payload Applications

Same Sky’s AMT series encoders are engineered to meet the stringent requirements of UAV payload systems, offering a range of features that align with the challenges of airborne electromechanical design:

- Capacitive Sensing Architecture: Unlike traditional optical encoders, AMT encoders leverage capacitive technology, providing superior immunity to environmental contaminants such as dust and moisture. This architecture also exhibits greater resilience to mechanical vibration—ideal for rotorcraft and fixed-wing platforms operating in harsh field conditions.

- Low Power Operation: AMT encoders are designed with power efficiency in mind, consuming minimal current. This is essential in UAV applications where energy budgeting is critical to maximising flight duration and mission capacity.

- Programmable Resolution: Engineers can digitally configure encoder resolution to match system-level requirements precisely, from high-speed actuation to fine-position feedback—without hardware changes.

- Modular and Compact Form Factors: The mechanically adaptable design of the AMT series simplifies integration into tight payload envelopes or customised assemblies. The availability of multiple mounting options and shaft configurations accelerates development and supports iterative prototyping.

- Reliability: By eliminating optical discs and having fewer moving parts, AMT encoders enhance shock tolerance and reduce susceptibility to failure from particulate ingress or mechanical wear.

- Versatile Output Options: Support for incremental, absolute, and commutation signal formats provides system architects with flexibility in selecting the most appropriate feedback protocol for brushless motor control, servo positioning, or data acquisition tasks.

These attributes make the AMT series a highly reliable and adaptable encoder platform for UAV engineers seeking precision, durability, and efficiency in payload motion control.

Conclusion

As UAV platforms evolve toward more specialised and mission-critical roles, the performance expectations placed on onboard systems, particularly payload mechanisms, are becoming increasingly stringent. Whether stabilising imaging equipment, regulating agricultural dispersal, or enabling next-generation applications yet to be defined, precise motion control is essential. At the core of these systems are encoders, which serve as the primary feedback elements in closed-loop control architectures.

Same Sky’s AMT series encoders offer a robust solution tailored to these needs, combining high-resolution feedback, low power consumption, environmental resilience, and configurable output formats. Their capacitive sensing architecture and modular mechanical design make them exceptionally well-suited for drone payload systems’ size, weight, and reliability constraints. As UAV applications expand, AMT encoders provide the precision and flexibility required to support the future of autonomous airborne systems.

Source: Mouser blog