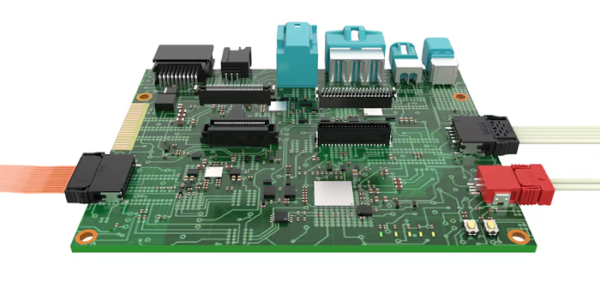

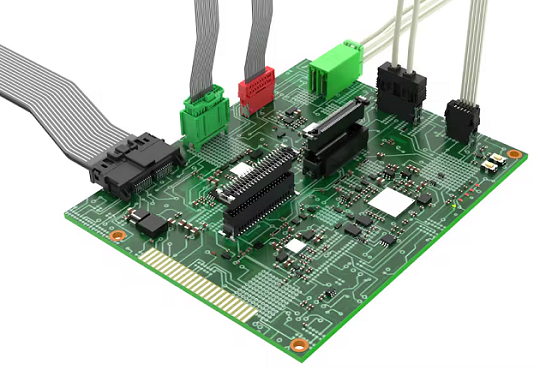

TE Connectivity (TE), a global leader in connectors and sensors, introduces its inside device connectivity portfolio designed to support the evolving needs of automotive electronic control units (ECUs) and next-generation vehicle platforms, including software defined vehicles. The portfolio includes board-to-board, wire-to-board, flex-to-board and wire-to-wire connector solutions, purpose-built for compact, high-performance applications.

These connectors are engineered for many application areas in a SDV, including those leveraging zonal architectures:

- Power conversion: On-board-Charger (OBC) inverter, DC/DC-converter

- Battery system: battery, cell module controller (CMC), battery management system (BMS)

- Electronic control units (ECUs)

- High-performance computers (HPCs)

- Black box application (e.g. lighting)

- ADAS technologies like radar and LiDAR

As modern electronic/electrical(E/E)architectures bring together HPCs, ADAS and intelligent battery systems, the need for fast and reliable inside device connectivity is growing. TE leverages its multi-faceted industry experience in consumer electronics, factory automation and automotive connectivity to deliver a portfolio optimized for EMI-sensitive and vibration-intensive environments.

The Inside Device Connectivity portfolio is tailored to the specific needs of SDVs by supporting platform strategies that enable scalable and standardized connector configurations. At the same time, the portfolio helps reduce weight, packaging space and integration complexity—key priorities for OEMs aiming for efficiency and modularity.

Key technical features of TE’s new inside device connectivity solutions:

- Connector technologies: flex-to-board, wire-to-board, board-to-board, wire-to-wire.

- Current capacity: up to 45 A (wire-to-board); up to 18 A (board-to-board).

- Pitch / pin count: 0.4–10.16 mm with up to 180 pins.

- EMI and mechanics: EMI-conscious designs with high misalignment tolerance, rugged for vibration, contamination, temperature shifts and humidity.

- Terminations: crimp, IDC and mass termination.

“With our Inside Device Connectivity portfolio, OEMs and Tier-1 suppliers can streamline assembly and reduce module footprints while maintaining current capacity and EMI performance—critical in HPCs, ADAS and battery systems. Backed by our global manufacturing and application engineering expertise, the portfolio empowers customers to accelerate development and integration across software-defined platforms and evolving architectures,” said Janet Wu, director of product management, TE Connectivity.

For more information, visit the Inside Device Connectivity landing page: https://www.te.com/en/industries/automotive/applications/in-device-connectivity.html

TE’s Inside Device Connectivity portfolio will also be on display at the upcoming Battery Show North America in Detroit, Michigan, Oct. 6-9.