The rise in the market for industrial radio frequency (RF) heating equipment is driven by producers’ adoption of energy efficiency, process control, and non-contact heating. RF heating is a process that uses electromagnetic fields in the 1–300 MHz range to generate heat directly in dielectric materials. Compared to conventional heating technologies, RF heating can provide faster and more uniform heating. It is especially effective in drying, sealing, curing, and preheating processes across various applications. As sustainability and productivity are prioritized in manufacturing, RF heating equipment will continue to emerge as an important enabling technology for advanced industrial thermal processes.

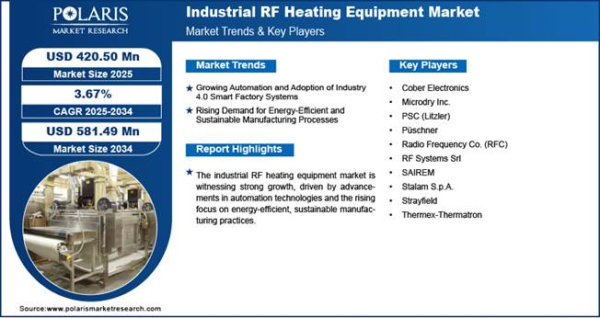

Key Market Stats

The global industrial RF heating equipment market stood at USD 405.90 million in 2024, according to the newly published research report by Polaris Market Research. The market is projected to account for a CAGR of 3.67% from 2025 to 2034.

Industrial RF Heating Equipment Types

Continuous Type

Continuous RF heating systems operate seamlessly in a one- or two-way mode for continuous processing in high-volume bulk loading. Materials continuously move through the heating section, receiving controlled energy input throughout the process. Continuous RF systems exhibit high uniformity and overall system yield. This enhances demand for consistent drying, preheating, and curing in textile, wood, food processing, plastic, and other high-volume applications. The continuous process provides uniform heating, minimal downtime, and maximum overall yield. Continuous RF heating systems can be integrated with automatic control systems so operators can modify temperature, energy input level, and exposure in real time while in process.

Batch Type

Batch RF heating equipment processes and exposes a single load at a time in a sealed chamber, with a specific amount of material. The form of equipment provides significant flexibility in handling heating parameters based on material sophistication or the strict energy input patterns required in the process. The processes include preheating or curing composite materials, drying delicate food products, or sterilizing medical or pharmaceutical items.

Industrial RF Heating Equipment Market Drivers

Rising Need for Energy Efficient Processing

Conventional heating methods like convection and conduction often result in energy loss because of superficial heating and lengthier heating times. RF heating, on the other hand, gives volumetric energy transfer, improving the efficiency of heating and reducing cycle time. As energy efficiency and green manufacturing become critical drivers, industries are moving toward RF systems with measurable cost and carbon calculations.

Advances in Material Processing Applications

Industries working with materials that are sensitive to moisture or complex are moving toward RF for reliable and controlled heating. This is the case in the food industry, where RF drying offers uniform removal of moisture with no loss in flavor or nutrition. Similarly, RF serves the same purpose in preventing warping and improving products in wood and other composite materials. These benefits will continue to broaden and deepen the industrial market.

Automation/Smart Manufacturing

As manufacturing facilities migrate to Industry 4.0 frameworks, RF heating equipment is now being integrated with digital monitoring, feedback control, and temperature sensing. This offers opportunities for energy management, predictive maintenance, and adaptive power control that would help improve reliability and throughput in continuous production lines.

Emerging Market Trends

Adoption in Medical and Pharmaceutical Industries

RF heating finds an increasing number of sterilization and drying applications with respect to medical devices, pharmaceuticals, and even packaging materials. Its capability for uniform temperature distribution and rapid processing makes it an attractive option in industries where quality control and hygiene are very crucial.

Shift to Renewable And Electrified Industrial Systems

With global energy systems increasingly moving to electrification, RF heating equipment aligns naturally with this trend. Compatibility of the equipment with renewable power sources positions the technology as a keystone technology in the decarbonization of industrial heat.

Focus on Customisation and Material-Specific Solutions

Manufacturers are offering RF heating solutions tuned to the specific dielectric properties of materials. Emphasis on customization improves performance and efficiency, thus finding more niche applications in advanced polymers, ceramics, and aerospace composites.

Conclusion

The industrial RF heating equipment market is poised to become a cornerstone for modern, sustainable industrial processing. With continuing developments in automation, power electronics, and process monitoring, RF heating systems will allow manufacturers to achieve high product quality and lower energy costs. As industries across the world continue to move toward electrified and intelligent production, the adoption of RF heating technologies is likely to accelerate in order to shape the future of industrial thermal processing.