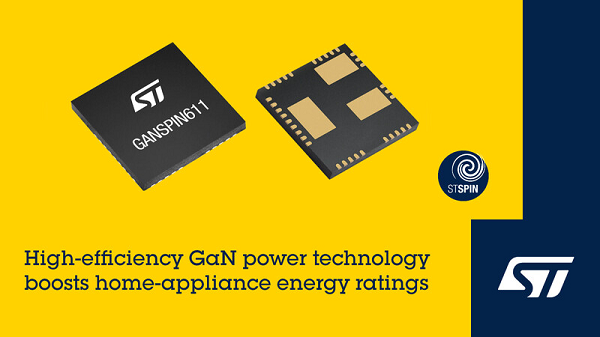

GaNSPIN GaN ICs:

- High-efficiency GaN power integrated technology tailored for motor drives in white goods and factory automation

STMicroelectronics, a global semiconductor leader serving customers across the spectrum of electronics applications, has unveiled new smart power components that let home appliances and industrial drives leverage the latest GaN (gallium-nitride) technology to boost energy efficiency, increase performance, and save cost.

GaN power adapters and chargers available in the market can handle enough power for laptops and USB-C fast charging to achieve extremely high efficiency to meet stringent incoming eco-design norms. ST’s latest GaN ICs now make this technology applicable to motor drives for products like washing machines, hairdryers, power tools, and factory automation.

“Our new GaNSPIN system-in-package platform unleashes wide-bandgap efficiency gains in motion-control applications by introducing special features that optimize system performance and safeguard reliability,” said Domenico Arrigo, General Manager, Application Specific Products Division, STMicroelectronics. “The new devices enable future generations of appliances to achieve higher rotational speed for improved performance, with smaller and lower-cost control modules, lightweight form factors, and improved energy ratings.”

The first members of ST’s new family, the GANSPIN611 and GANSPIN612, can power motors of up to 400 Watts including domestic and industrial compressors, pumps, fans, and servo drives. Pin compatibility between the two devices ensures designs are easily scalable. GANSPIN611 is in production now, in a 9mm x 9mm thermally enhanced QFN package, from $4.44.

Visitors to SPS – Smart Production Solutions 2025, 25-27 November, at the Nuremberg Exhibition Center, can see the GaNSPIN motor controllers at ST’s booth, no. 271 in Hall 4.

Technical notes on GaNSPIN drivers:

In the new GaNSPIN system-in-package, unlike in general-purpose GaN drivers, the driver controls turn-on and turn-off times in hard switching to relieve stress on the motor windings and minimize electromagnetic noise. The nominal slew rate (dV/dt) of 10V/ns preserves reliability and eases compliance with electromagnetic compatibility (EMC) regulations such as the EU EMC directive. Designers can adjust the turn-on dV/dt of both GaN drivers to fine-tune the switching performance according to the motor characteristics.

With RDS(on) of just 138mΩ in the GANSPIN611 and 270mΩ in the GANSPIN612, the GaN transistors minimize power dissipation and associated self-heating. This lets power components operate without a heatsink in many applications, thereby reducing the bill of materials, while also reducing circuit footprint by up to 60% to permit a smaller, lower-cost PCB.

Further features include:

- System-in-package with driver and half-bridge power stage with latest-generation 650V GaN power transistors for driving 3-phase BLDC motors

- Integrated bootstrap diode for high-side circuitry

- Suitable for universal 110V – 230V AC offline-powered appliances

- Fault-sensing comparator for smart shutdown provides fast-acting overcurrent protection with programmable disable time

- Undervoltage lockout (UVLO), overvoltage, overcurrent, thermal, and interlocking protection

- Wide supply and input-voltage range up to 20V, for robust and easy conversion of traditional power stages

- Standby pin for power saving