Highlights:

- Talga has applied for a transformative 1.1 billion SEK (~A$180 million) ‘Industrial Leap’ grant from the Swedish Energy Agency (“Industriklivet 2”), with the outcome expected in Q1 CY2026

- If approved, this grant complements the existing €70 million (~A$120 million) EU Innovation Fund grant and €150 million (~A$260 million) pre-approved EIB loan for the integrated Vittangi Anode Project, potentially providing funding required for an initial commercial 5,000 tpa plant to produce both sustainable Talnode-C and Talnode-R

- Request for Proposal (RFP) process with customers validates strong demand, securing expressions of interest for over 80% of initial capacity in 2028, with growth supporting phased scaling to 24,500 tpa total

Battery materials and technology company Talga Group Ltd is pleased to announce significant progress in its funding initiatives towards commercial-scale production from its proposed Luleå Anode plant in Sweden, a designated EU Strategic Project.

‘Industrial Leap’ Grant Application

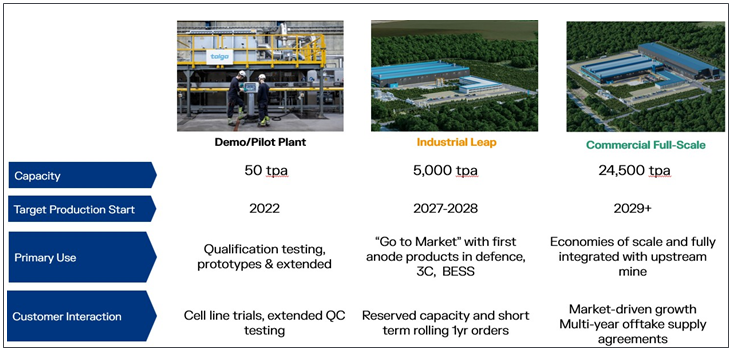

Talga has applied for a 1.1 billion SEK (~A$180 million) grant under the Swedish Energy Agency’s Industrial Leap (“Industriklivet 2”) program, as part of a 3.1 billion SEK (~A$500 million) project to construct a 5,000 tonnes per annum (tpa) anode production facility at the Company’s fully permitted site in Luleå, Sweden.

The project represents Talga’s “Industrial Leap” from its existing Electric Vehicle Anode (EVA) demonstration plant to commercial scale production of Talnode-C and Talnode-R sustainable graphite anode products. The ‘Industriklivet 2’ funding, if granted, is anticipated to be confirmed in the first quarter of CY2026 and follows Talga being awarded the ‘Industriklivet 1’ program grant in October 2025 (ASX:TLG 17/10/2025 and ASX:TLG 20/11/2025).

Integration with Existing Funding Stack

Talga’s aim is that the Industriklivet 2 funding, upon granting, could complement Talga’s established funding sources, including a €150 million (~A$260 million) loan from the European Investment Bank (EIB) (currently undrawn) and a €70 million (~A$120 million) grant from the EU Innovation Fund. This combined funding stack positions Talga with a substantial amount of the capital required for the initial 5,000 tpa commercial-scale anode production line, including associated plant and infrastructure for the larger Luleå anode plant.

Negotiations are underway with funding providers to refine and finalise the packages, with completion targeting the end of the second quarter of CY2026 to align with completion of final engineering and design on the anode plant partly funded under Industriklivet 1.

This non-dilutive funding stack underscores the Company’s focus and progress in de-risking its Vittangi Anode Project and advancing towards commercial production.

Customer RFP process

Talga has reached key milestones in the customer validation and sales pipeline, as outlined in the recent Quarterly Activities Report (ASX: TLG 30/10/2025). Successful qualification and technical validations with five battery manufacturers across sectors for battery energy storage (BESS), defence, high- powered EVs, robotics and consumer electronics have confirmed product fit.

Customer pricing indications support the business case for near-term execution with initial anode quantities supplied from the EVA plant in 2026, before commencement of the 5,000 tpa commercial output. Expressions of interest now cover more than 80% of the initial 5,000 tpa capacity, with ongoing programs and negotiations underway to secure contracts on full production.

Scaled Commercialisation to 24,500 tpa

Talga’s modular design strategy enables a phased ramp-up following the 5,000 tpa line, which has an expected 18-month construction timeline from Final Investment Decision (FID). The Company intends to ramp-up to its 19,500 tpa ‘Stage 1’ Talnode®-C capacity at Luleå, taking total anode production capacity to 24,500 tpa.

The key elements of the 5,000 tpa stage commercialisation includes:

- Site preparation works, buildings, HVAC and utilities to support full Stage 1 production capacity.

- Installation of the first purification and coating line (of four planned), with ancillary equipment capable of treating Talga’s existing Vittangi graphite stockpiles and recycled anode feedstock

Talga expects that the majority of initial construction and site establishment costs being met in Industriklivet 2 will reduce future capital needs for full ramp-up. This staged commercialisation approach delivers potentially significant strategic and material advantages including:

- Minimises upfront equity requirements and overall capital intensity

- Mitigates execution risks on path to full Stage 1 development

- Establishes Talga as Europe’s sole integrated anode supplier, with both natural and recycled (synthetic) anode products

- Enhances efficiencies through increased Stage 1 Refinery capacity to 24,500 tpa (previously 19,500 tpa) from existing 4-line equipment design.

- Initiates platform for further customer demand and industry grant funding

Talga’s CEO, MP, commented: ” We are delighted to be on the cusp of securing funding for the first commercial scale anode production line with this grant application combined with our existing financial commitments from the EU and EIB. The Industriklivet 2 grant, if received, is pivotal in the advancement of our go-to-market strategy to commercialise the anode products that our customers have successfully qualified. This ‘Industrial Leap’ not only scales our operations but also positions Talga as a key player in Europe’s battery supply chain, delivering innovative, low-emission anode solutions.”