The rapid growth of electric vehicles has made battery management systems more important than ever. These systems do more than monitor battery voltage and temperature—they protect battery health, optimize energy use, and ensure reliable vehicle performance over time.

Modern EV batteries, particularly those using high-energy-density chemistries such as Nickel-Manganese-Cobalt and Lithium Iron Phosphate, present unique challenges. Increased capacity and faster charging put more stress on individual cells, making accurate monitoring, predictive maintenance, and adaptive management essential for safety and longevity.

Artificial intelligence is revolutionizing battery management systems by turning them into smart, adaptive brains. AI enhances real-time monitoring, predicts battery degradation, optimizes charge and discharge cycles, and makes data-driven decisions that improve performance.

A key trend is edge computing, which processes battery data locally within the vehicle rather than relying on the cloud. This allows instantaneous responses, which are critical for fast-changing driving conditions and maintaining battery safety.

What is a Battery Management System and Why Is It Essential?

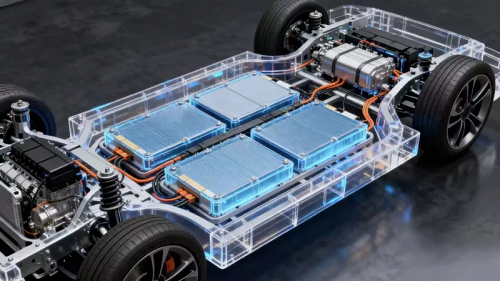

A battery management system is the nervous system of an electric vehicle battery pack. It constantly monitors voltage, current, and temperature across all cells, protecting the battery from overcharging, deep discharge, and thermal issues.

It also estimates key parameters:

- State of Charge (SoC): The amount of energy remaining in the battery

- State of Health (SoH): The overall condition and aging level of the battery

- State of Power (SoP): The available output under current operating conditions

A smart battery management system balances cells, manages charging cycles, and ensures the battery remains in optimal condition under all operating scenarios. Without an effective BMS, battery safety, efficiency, and lifespan would be significantly compromised.

Current Challenges in EV Battery Management

Battery safety remains the most critical challenge for EV manufacturers. Although fires are rare, even minor incidents can have significant regulatory and reputational consequences. AI-enhanced BMS can proactively detect early signs of thermal runaway, cell degradation, or voltage irregularities, allowing interventions before critical failures occur.

Reliability and performance expectations are also increasing as drivers demand longer ranges and faster charging. Traditional systems struggle with rapid charge-discharge cycles and uneven energy distribution in high-capacity batteries. AI-based systems can dynamically balance cells, adjust charging rates, and predict optimal energy usage to maintain consistent performance under varying conditions.

Battery longevity and second-life applications are another challenge. As EV adoption grows, manufacturers need to ensure battery packs retain performance for eight to ten years or more. AI-driven predictive maintenance detects early signs of capacity loss, thermal stress, or imbalanced cells, enabling timely interventions to extend usable life and maintain warranty compliance.

Furthermore, modern EV batteries often interact with smart grids and renewable energy systems. Vehicle-to-grid applications or regenerative braking introduce complexity to battery management. AI supports real-time decision-making to optimize energy distribution while maintaining safety and performance, which is particularly important for fleets and large-scale deployments.

According to Persistence Market Research, the global automotive battery management market is expected to grow rapidly in the coming years, driven by increasing EV adoption, advanced battery chemistries, and the integration of AI-driven management systems.

How AI Improves Accuracy in SoC and SoH Estimations

State of charge and state of health are fundamental metrics for EV battery operation. SoC indicates remaining energy, while SoH measures the battery’s overall health and degradation level. Traditional methods rely on basic algorithms or fixed lookup tables, which often fail to capture the nonlinear behavior of modern high-capacity batteries.

AI and machine learning improve accuracy by analyzing large datasets from real-world usage. These models detect subtle correlations between voltage fluctuations, temperature changes, and current flow, which can indicate early-stage battery stress or inefficiencies. The result is more precise range predictions and greater driver confidence.

Hybrid approaches that combine physics-based simulations with data-driven AI models provide even higher reliability. By continuously learning from real-time operational data, these systems adjust predictions dynamically to compensate for battery aging, temperature variations, and variable driving conditions.

AI-driven SoC and SoH predictions also enable smarter energy management for vehicle fleets. Fleet operators can schedule maintenance more effectively, optimize charging infrastructure usage, and extend battery life, reducing overall costs and supporting sustainability.

Factors Affecting Battery Aging and How AI Helps

Battery aging is influenced by charge-discharge cycles, depth of discharge, operating temperature, and high charge or discharge rates. Repeated exposure to extreme conditions accelerates capacity loss, reduces efficiency, and increases the risk of failure over time.

AI-enhanced BMS optimizes charging cycles and energy distribution to reduce battery stress. Adaptive algorithms can limit charging rates when cells are hot or redistribute loads across cells to prevent localized degradation, extending overall battery life.

Predictive models allow manufacturers and fleet managers to anticipate battery degradation before it impacts performance. By analyzing historical usage and real-time data, AI recommends maintenance schedules, energy-saving driving strategies, and optimized charging practices tailored to each battery pack.

AI is also critical for second-life applications. By monitoring health metrics continuously, the system ensures retired batteries are suitable for energy storage or grid support, maximizing lifecycle value and supporting circular economy initiatives.

Why Edge Computing Matters for AI BMS

Processing AI computations on-board allows real-time decision-making without cloud dependency. This is essential for scenarios where latency could compromise safety, such as sudden acceleration or regenerative braking.

Edge AI also enhances cybersecurity because sensitive battery data remains within the vehicle. Self-learning BMS can continuously refine predictive models based on live driving data, improving performance, reliability, and safety.

Microcontroller Considerations for AI-Driven BMS

To implement AI effectively, microcontrollers must handle high-speed sensor data, perform AI inference, and maintain low energy consumption. Essential features include:

- High-performance digital signal processing

- Integrated AI accelerators or neural processing units

- Low-power operation for embedded efficiency

- Real-time operating system support

- Compliance with functional safety standards

These capabilities ensure real-time monitoring, predictive analysis, and adaptive energy management, making the BMS smarter and more reliable.

Enhancing Fault Detection with AI

Traditional threshold-based fault detection can miss subtle early issues. AI identifies anomalies in voltage, current, and temperature at the cell level, enabling preemptive actions such as load redistribution or thermal adjustments.

This proactive approach reduces the risk of failure, extends battery life, and improves overall safety. AI also supports intelligent cell balancing, ensuring even charge distribution across the battery pack and minimizing stress on individual cells.

Industry Trends and Developments

The AI-driven BMS market is projected to grow rapidly as EV adoption increases. Innovations such as predictive maintenance, adaptive charging, and real-time fault detection are bridging the gap between battery safety and high-performance operation. Digital twin simulations allow manufacturers to virtually monitor battery health in real time, enabling faster responses to potential issues and more efficient energy management.

Smart battery management systems are becoming central to the future of electric vehicles, combining AI intelligence, edge computing, and adaptive control to improve safety, reliability, and longevity.