Increased efficiency and quality assurance are just two of many topics relevant to industrial manufacturing. Against this backdrop, preeflow by ViscoTec is now releasing new features for the eco-CONTROL EC200 2.0 that will benefit all users in the future.

In general, preeflow control units simplify every dispensing process. They are perfectly suited for all dispensers in the eco-PEN, eco-DUO, and eco-SPRAY series. They are available as tabletop, monitor, or built-in versions. They combine many advantages in one device, such as intuitive control of the preeflow dispenser series, user-friendly program creation, comprehensive process monitoring including data export, and advanced error analysis and troubleshooting. In addition to the existing advantages, there are now even more useful features:

Feature 1: Preventive maintenance – predictive service for consistently stable dosing quality

The Preventive maintenance feature will now alert users to upcoming maintenance via a visual status indicator in the form of a progress bar. The interval for this is fixed. This feature also includes a display for upcoming stator replacement. The interval for this replacement is based on the individual dosing process. The value is taught by measuring the time from the first stator replacement to the next. Informative text messages also appear before the intervals expire. Preventive Maintenance enables companies to ensure a consistently high standard of quality and precise dosing results.

Feature 2: External stop – greater process reliability thanks to intelligent error detection

External stop allows the dosing control system to be seamlessly integrated into complex plant environments for the first time. This feature monitors external devices and automatically responds to their error messages. If the control system detects a malfunction, it stops the dosing process within milliseconds, thus preventing defective components or unplanned system states. As soon as the external device is working properly again, the error can be conveniently acknowledged – either directly at the control system or via an external signal. Companies thus benefit from greater process reliability, more reliable processes, and clear error communication across all systems involved.

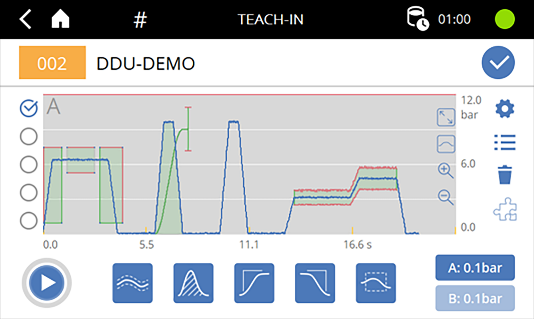

Feature 3: Component signal – ensure complete component quality with just one pressure measurement

The Component signal makes it possible to bundle several short dispensing operations on a component into a single pressure recording. This results in an overall evaluation of the entire component for the first time – instead of individual isolated dispensing points. Especially for applications such as dot or bead dispensing on the same component, this feature ensures that the entire dosing pressure curve is evaluated consistently. Users receive a complete quality report that accurately shows whether all dosages on the component were within the specifications. The result: better traceability, reduced testing effort, and a significant gain in process reliability.

Feature 4: Integral – precise quantity monitoring for short dosing cycles

With Integral, the total dosed quantity is calculated based on the time integral of the dosing pressure. This is a particularly reliable method for short, selective dosing, where it is not the pressure curve, but the actual dosing quantity achieved that is decisive. At the end of the dosing interval, the control system compares the value determined in this way with a previously learned reference within a tolerance range. This allows an immediate assessment of whether the target quantity has been reached. This ensures robust quality control, even with very short process times, reduces scrap, and guarantees consistently precise dosing results.

For more information, visit www.preeflow.com.