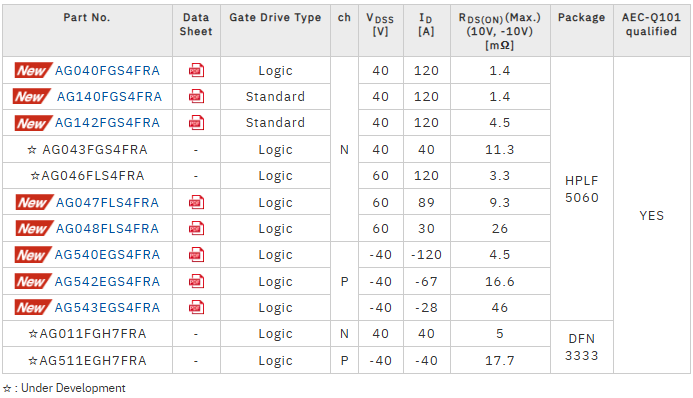

ROHM has expanded its lineup of low-voltage (40V/60V) MOSFETs for automotive applications – such as main inverter control circuits, electric pumps, and LED headlights – by introducing latest products adopting the new HPLF5060 package (4.9mm × 6.0mm).

In recent years, automotive low-voltage MOSFETs have been trending toward smaller packages, such as the 5060-size and even more compact options. However, this miniaturization introduces significant challenges for achieving reliable mounting, primarily due to narrow terminal spacing and leadless designs.

To address these issues, the new HPLF5060 package offers a smaller footprint compared to the widely used TO-252 package (6.6mm × 10.0mm) while enhancing board-mount reliability through the adoption of gull-wing leads. Additionally, the use of copper clip junction technology enables high-current operation, making the HPLF5060 an ideal solution for demanding automotive environments.

Mass production of new products using this package began in November 2025 (sample price: $3.5/unit, excluding tax). Online sales have also started, and the products is also available for online purchase through online distributors such as DigiKey and Farnell.

In addition to expanding the lineup of products using this package, mass production of the smaller DFN3333 (3.3mm × 3.3mm) package, which employs wettable flank technology, is scheduled to begin around February 2026. Furthermore, development has commenced on a TOLG (TO-Leaded with Gull-wing) package (9.9mm × 11.7mm) to further expand the lineup of high-power, high-reliability packages.

Application Examples

Main inverter control circuits, electric pumps, LED headlights, etc.

Terminology

Gull-Wing Leads: A terminal structure that spreads outwards from both sides of the package. It achieves excellent heat dissipation along with increased mounting reliability. It is called “Gull-Wing” because its appearance resembles the wing of a seagull.

Copper Clip Junction Technology: A technology that uses copper clips (flat metal bridges) to connect chips and lead frames directly, replacing the conventional wire bonding method.

Wettable Flank Technology: A technology for plating the sides of the lead frame on bottom electrode packages such as QFN and DFN to improve mounting reliability.

For more information, visit www.rohm.com.