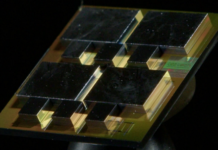

Researchers at CEA-Leti and CEA-IRIG-SyMMES have validated a chip-scale electron paramagnetic resonance (EPR) spectrometer that achieves unprecedented scan speed, spectral span, and sensitivity from a battery-operated integrated circuit. By replacing the bulky electromagnets used in conventional EPR instruments with an ultra-fast frequency-scanned architecture, the system enables high-performance paramagnetic sensing in portable and space-constrained environments where traditional systems cannot operate.

SyMMES, the Molecular Systems and (Nano)Materials for Energy and Health Laboratory, is one of IRIG’s joint research units (UMR 5819). It brings together staff from CEA, the French National Centre for Scientific Research (CNRS), Grenoble-Alpes University, and Grenoble INP Graduate schools of Engineering and Management, Université Grenoble Alpes.

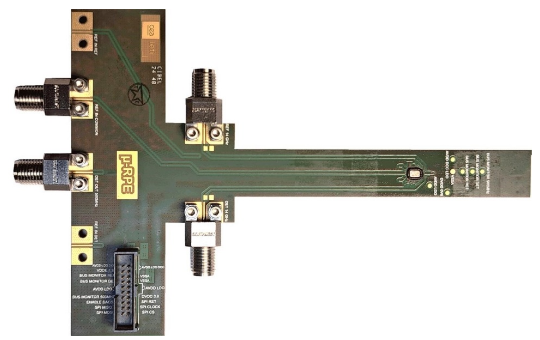

The results were presented today at ISSCC 2026 in the paper “A 1400 THz/s Ultra-Fast-Scan 14 GHz EPR-on-a-Chip Based on Injection-Locked Phase Detection Featuring 120 µM Concentration Sensitivity.”

Miniaturized EPR spectrometers transform a complex laboratory instrument into a portable, low-power microchip capable of detecting reactive chemical species that influence energy storage, materials reliability, environmental safety, and biomedical processes. By eliminating the bulky electromagnet that traditionally limits EPR instruments to centralized facilities, this technology, sometimes dubbed “EPR-on-a-chip”, makes it possible to perform high-precision analysis directly in the field, at industrial sites, or inside research systems where traditional tools don’t fit.

Record Performance at Milliwatt Power Levels

The system delivers:

- 1,400 THz/s scan rate

- 100-Gauss equivalent spectral span

- 120 µM concentration sensitivity

- 96 mW power consumption

- 200 ns scan time across the full span

This performance exceeds that of state-of-the-art miniaturized EPR devices, which typically trade sensitivity and spectral range for speed. The combination of ultra-fast scans and wide spectral coverage enables observation of fast-passage effects and transient phenomena in chemical reactions that are difficult or impossible to capture with existing systems.

New Applications Across Healthcare, Materials, and the Environment

By shrinking EPR to chip scale, CEA-Leti and CEA-IRIG open new application paths in healthcare diagnostics, materials characterization, and environmental monitoring. Portable, low-power EPR sensing could support on-site chemical analysis, embedded monitoring in research systems, and distributed sensing networks.

As development advances toward a full prototype, the technology represents a significant step toward making high-precision spectrometry more accessible and deployable beyond the laboratory.

Injection-Locked Phase Detection Enables High Sensitivity

At the core of the system is an original injection-locked phase-detection architecture that encodes the EPR signal as a phase shift rather than an amplitude or frequency change. By exploiting the intrinsically low phase noise of injection-locked oscillators, the design achieves unprecedented sensitivity for a single-sensor, chip-scale EPR system.

“Our goal is to create a compact, portable EPR spectrometer that operates on just a few watts of power, enabling on-site analysis in environments where conventional instruments simply cannot operate,” said Serge Gambarelli, research director at CEA-IRIG and EPR spectroscopy expert.

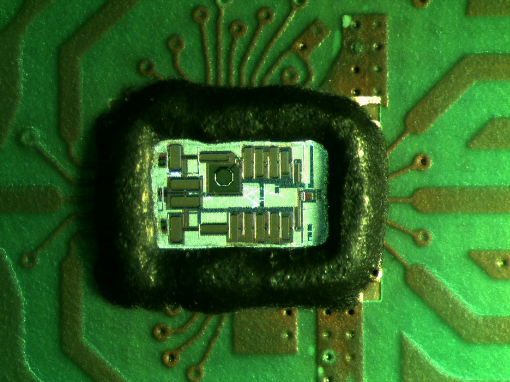

“By adapting RF and frequency-synthesis architectures originally developed for telecommunications, we were able to integrate a complete EPR system on a single 22 nm chip,” said Alexandre Siligaris, senior research engineer at CEA-Leti.

A Milestone for European Scientific Instrumentation

The circuit is the first scientific instrument fabricated using the advanced 22 nm FDSOI technology. While manufactured by GlobalFoundries, an international fab partner of CEA, the system architecture, circuit design, and measurement approach were fully developed and patented by CEA.

The work marks a major milestone in CEA’s Moonshot µ-RPE program, which aims to develop a compact, deployable EPR spectrometer to support key missions of CEA—and highlights Europe’s leadership in advanced microelectronics for scientific instrumentation.

The Moonshot program also includes R&D on planar magnets, which are key to future spectrometers, because they increase the number and field of applications.

“Typically applied in electric mobility and energy transition sectors, this expertise is now being leveraged to design the magnetic system for the µ-EPR spectrometer, demonstrating a valuable transfer of knowledge into the field of instrumentation,” said Celine Delafosse, laboratory manager at CEA-Liten, which is leading that research area.

For more information, visit www.leti-cea.com.