Most people come into contact with at least one piezoelectric sensor every day – whether at work, while receiving medical treatment or simply using their phone. Although they have become standard in both production processes and commodities across multiple industries over the past six decades, they are still plagued by the issue of picking up on ‘white noise’ and returning false readings.

This can have serious real-world ramifications for medical professionals relying on these sensors to diagnose patients, or for engineers assessing structural damage after an earthquake.

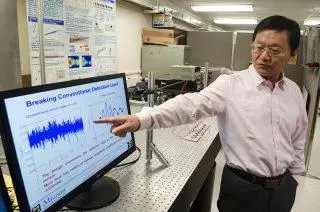

Fortunately, a team led by Guoliang Huang, an associate professor of mechanical and aerospace engineering at the University of Missouri, has developed a new sensing platform using metamaterials that improves the sensitivity of piezoelectric sensors while simultaneously cutting their cost.

Their results were recently published under the title “Enhanced flexural wave sensing by adaptive gradient-index metamaterials” in the journal Scientific Reports.

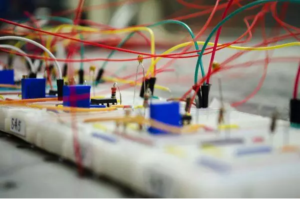

The new sensing platform can be ‘tuned’ using an electric signal, which, when connected to circuit boards with sensors, can pick up weaker signals that previously could not be detected.

“In the past, methods to produce signal intensification only have included electrical amplification,” Huang explained. So his team attempted what Huang described as “a novel combination of mechanical and electrical amplification, overcoming the limitations of using just electrical amplification.”

Their results are the first demonstration of a metamaterial being used in this way.

This development could cut costs for manufacturers, as the amplified signal allows the sensor to capture more data. It also lengthens the range of the sensors so fewer are needed for larger applications across distances.

“Now we can, for any sensing transducers, by attaching our platform, make your signal amplification two orders higher,” said Huang.

This isn’t Huang’s first foray into the use of metamaterials. His previous research developed a method of controlling elastic waves, another discovery with wide-reaching applications for everyday use in military, medical, and aerospace technology.

Huang and his team’s current research is focused on developing an active metamaterial through the use of electronically-controlled elements. They are funded by a grant from the U.S. Air Force Office of Scientific Research with program manager Byung-Lip (Les) Lee.

Source: http://www.engineering.com/