Testing is an integral part of electronic equipment manufacturing process. It ensures that defects in electronic circuits are identified and resolved before a product is assembled and sold to intended customers. Electronic circuits are considered the most vital part of any electronic product. Before assembling electronic equipment, proper testing must be done at various stages on all components.

Whether you’re an electronics manufacturing service (EMS) provider, an electronics enthusiast, or an original equipment manufacturer, testing electronic circuits should be at the heart of everything you do. To successfully carry out electronic circuit tests, there are different methods you should use before final assembly. Below, we explore the main types of tests.

ICT (In-Circuit Test)

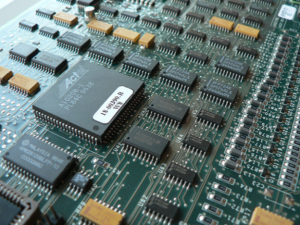

In-circuit test is a type of automated electronic equipment testing method. It’s mainly used for testing individual components like diodes, capacitors, and transistors of a printed circuit board, otherwise known as PCB. You can use this test method for detailed manufacturing defects analysis and to identify faults like short circuits, open circuits, and resistance. It’s also reliable for testing basic supply voltage measurements on circuit board components.

To successfully do an ICT, you’ll need a bill of materials (BOM), a dedicated test program, CAD design data and schematics, and a “bed of nails” test fixture. You’ll need sample PCBs, both populated and unpopulated for testing purposes and to make sure your fixtures are fitted and assembled as they should. ICT is widely considered an accurate form of testing electronic circuits, despite the high initial investment needed.

Flying Probe

This is another standard testing method you can use when testing electronic printed circuit boards (PCBs) before assembly. It allows you to do a limited optical inspection of electronic circuit components that you can’t access electrically. You do this by using four probes that you can program and reprogram for each circuit board design.

The testing method is suited for low-volume testing and in cases where the design of an electronic product is likely to change over time. It’s also ideal for testing electronic circuit boards that don’t come designed with test pads.

Boundary Scan Test

Before assembling electronic products, you need to carry out a boundary scan test to ensure that all digital devices on your printed circuit boards are connected. Most digital integrated circuits will not need any physical test probes or complex debugging. To use this test, you need a custom software program that helps detect and report any missing pins on printed circuit boards.

This test method is intuitive, reliable, and fast when it comes to identifying structural fault locations, diagnosing digital circuits, and delivering ICT levels of test coverage. The test offers similar coverage to in-circuit testing, but is much slower.

Other Tests

Most electronic component manufacturers and manufacturing service providers may also carry out additional tests before assembling electronic products. For instance, you can subject your circuit boards to mechanical shock or vibration tests to identify any component manufacturing defects.

It’s also vital to do a functional test of your electronic equipment or product at the very end just before the final assembly process. During such tests, you may identify floating pins on your integrated circuits, wrong value or missing components, and other undetected errors.

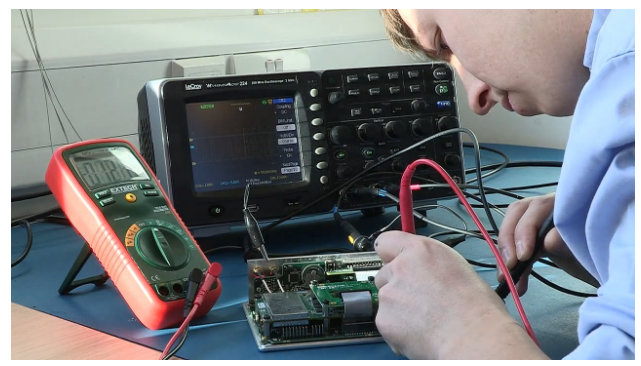

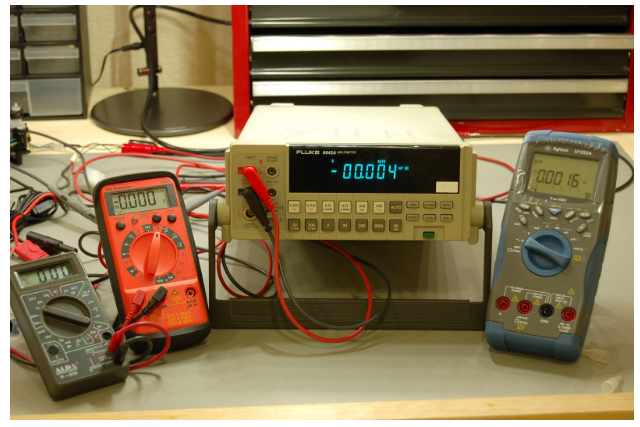

Electronic Circuit Test Equipment

Using the right testing equipment is vital when it comes to testing electronic components and circuit boards. To meet your test and measurement requirement needs, you can search for reputable companies that specialize in selling or leasing new and used testing equipment. Apart from it or being 100% sure, you can contact to test and tag specialist.

Why is Testing Electronic Circuits So Important?

Testing confirms that an electronic equipment or product has been manufactured correctly and therefore, if the design and assembling are okay, it should do what it’s supposed to do. Following proper testing procedures for electronic circuits ensures that you produce high-quality products that meet your customer’s requirements.