What is an OLED?

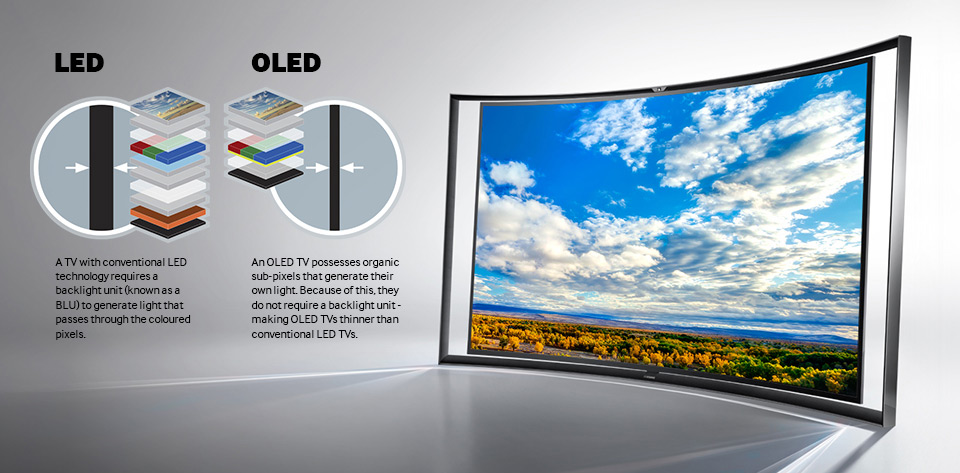

OLED is a flat light emitting technology, made by placing a series of organic thin films between two conductors. When electrical current is applied, a bright light is emitted. OLEDs can be used to make displays and lighting. Because OLEDs emit light they do not require a backlight and so are thinner and more efficient than LCD displays(which do require a white backlight).

How do OLEDs work?

An OLED is made by placing a series of organic thin films between two conductors. When electrical current is applied, a bright light is emitted.

OLED panels are made from organic (carbon based) materials that emit light when electricity is applied through them. Since OLEDs do not require a backlight and filters (unlike LCD displays), they are more efficient, simpler to make, and much thinner – and in fact can be made flexible and even rollable. OLEDs have a great picture quality – brilliant colors, infinite contrast, fast response rate and wide viewing angles. OLEDs can also be used to make OLED lighting – thin, efficient and without any bad metals.

OLED materials have been discovered back in 1960, but only in the past 20 years or so have researchers started to actually work on the technology.

The main component in an OLED display is the OLED emitter – an organic (carbon-based) material that emits light when electricity is applied. The basic structure of an OLED is an emissive layer sandwiched between a cathode (which injects electrons) and an anode (which removes electrons). Modern OLED devices use many more layers in order to make them more efficient and durable, but the basic functionality remains the same.

How an OLED panel is made

An OLED panel itself is made from a substrate, backplane (electronics – the driver), front plane (the organic materials and electrodes as explained above) and an encapsulation layer. OLEDs are very sensitive to oxygen and moisture and so the encapsulation layer is critical.

The substrate and backplane of an OLED display are similar to those of an LCD display, but the front plane deposition is unique to OLEDs. There are several ways to deposit and pattern the organic layers. Currently most OLED displays are made using vacuum evaporation, using a Shadow Mask (FMM, Fine Metal Mask) to pattern. This is a relatively simple method but it is inefficient (a lot of material is wasted) and very difficult to scale up to large substrates.

Some OLED materials are soluble, and these can be deposited using printing methods – mostly ink-jet printing. This technology is not commercialized yet, but OLED makers hope that ink-jet printing may be a scalable, efficient and cheap way to deposit OLEDs.

Difference OLED vs LCD

An OLED (Organic Light Emitting Diodes) panel is made from organic (carbon-based) materials that emit light when electricity is applied. An OLED TV is made from millions of pixels, each made from red, green and blue tiny OLED materials.

A LED TV is a confusing term – as it should actually be called LED-backlit LCD. This is still LCD technology, but instead of the fluorescent (CCFL) lamps, an LED TV uses LED lighting for the white backlighting. While LED LCD TVs look better than CCFL LCDs, they are still no match for OLED panels.

OLED displays have the following advantages over LCD displays:

- Improved image quality – better contrast, higher brightness, fuller viewing angle, a wider color range and much faster refresh rates.

- Lower power consumption

- Simpler design that enables ultra-thin, flexible and transparent displays

- Better durability – OLEDs are very durable and can operate in a broader temperature range

OLED disadvantages

OLEDs aren’t perfect. First of all, today it costs more to produce an OLED than it does to produce an LCD – although this should hopefully change in the future, as OLEDs has a potential to be even cheaper than LCDs because of their simple design.

OLEDs have limited lifetime (like any display, really), that was quite a problem a few years ago. But there has been constant progress, and today this is almost a non-issue. Today OLEDs last long enough to be used in mobile devices and TVs. OLEDs can also be problematic in direct sunlight, because of their emissive nature. But companies are working to make it better, and newer AMOLEDs (such as Samsung’s Super AMOLED and Super AMOLED Plus and Nokia’s CBD displays) are quite good in that respect – some even consider them superior to LCDs.

for more information visit:- https://www.oled-info.com