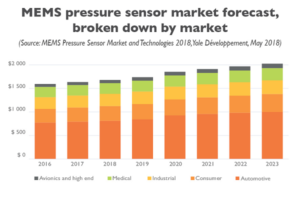

The MEMS pressure sensor market is still driven by automotive applications. Established automotive applications increase MEMS pressure sensors adoption in the integrating systems, and also widespread their geographical adoption especially in China thanks to new automotive regulation.

Consumer is the second pressure sensor business with new consumer applications including wearables, electronic cigarette, drones… which are giving attractive perspectives to the devices’ manufacturers.

MEMS pressure sensor technologies are basically segmented into piezoresistive and capacitive categories. Both two technologies are not hugely different in terms of performance but capacitive is limited to absolute pressure applications. Today piezoresistive is leading the industry in terms of market share, and that will probably continue in the future despite growing adoption of capacitive technology in consumer application.

Analysts compare the devices that use piezoresistive or capacitive technology, manufactured with bulk micromachining or surface micromachining processes, first level packaging or module packaging, monolithic or multi-chip structures. The team looks at their package dimensions and internal structures, MEMS and ASIC dies, die dimensions and package cross-sections, to provide a comprehensive review of MEMS pressure sensors. A detailed description of System Plus Consulting report is available: Here.