Trends in the automotive market are governed by two major factors in our country – norms set by the Government of India for safety and pollution control and customer preferences. In the recent past, GoImade it mandatory to have AHO (Auto headlamp ON) for two wheelers. OEM’s have implemented it in different ways – some models have headlamp always ON, which continuously drains vehicle battery, however vehicles with full LED headlampdo not consume much power compared to bulb based head lamp; some models have LED based DRL (day time running lamp) which is separate from actual headlamp and consumes very minimal power.

High efficiency, extended life of lighting system, enhanced driver andpedestrian safety, enhancing the driving experience, vehicle styling, aesthetic – are major factors moving the automotive industry towards LED based designs instead of conventional halogen bulb based designs.In the past year and a half, a significant number of four wheelers and two wheelers have been launched in India, where one or more, or even all the light loads are implemented using LEDs. And this number is increasing continuously.

It is worth understanding the difference between LED based system and bulb based system-

- Halogen bulb based systems draw very high current during startup till the time filament in the bulb heats up.

- For the same amount of light output, average power consumed by this type of bulb is more than double as compared to LEDs. This means, LEDs reduce load on battery, which reduces operating cost. Itcan also potentially reduce cabling weight.

- With LEDs, due to higher efficiency and more light output, overall heating is much lower, which improves lifetime of the system and reduces maintenance cost in the long run.

- Yellow halogen light illuminates very short distances or even reflects against dense fog. LEDs produce a much more penetrating, illuminating white light. This results in clearer driving conditions and easier to see in fog and other poor visibility conditions.

- In LED based automotive lighting systems, total light output is produced by multiple LEDs as compared to single light source in conventional designs. This produces more uniform illumination across required area. It also allows formation of sharp beams for adaptive lighting systems.

There are many advantages of using LED based lighting systems in vehicles, but isn’t free! LEDs require constant current source to produce constant intensity. LEDs are sensitive to over voltage and over current conditions; hence an intelligent circuit is required between battery power and LED load to safely operate it in a vehicle. In addition, automotive industry has set several stringent EMI/EMCstandards to limit amount of radiated and conducted noise generated by these systems so that it doesn’t interfere with operation of other systems in vehicle, for example radio. These systems should also be immune to external conducted and radiated noise for reliable operation. In addition, OEMs also have requirements of fault reporting and diagnostics for LED drivers.

Automotive LED driver devices from Texas Instruments (going forward will be referred to as “TI”) help you build innovative, reliable, cost effective automotive lighting systems that exceed the auto industry’s stringent requirements. Based on LED current, input voltage range, efficiency, PCB size and diagnostics requirements, circuit designers can select a suitable driver from a wide range of linear and switching current regulators.

For vehicles with 12V battery, minimum voltage can go below 6V during cranking and it can be as high as 40V (after TVS clamp) during load-dump conditions. OEMs specify input voltage range for which constant light intensity is expected from the LED load. If intensity is allowed to dim below 9V, then linear drivers are most suitablefor low current loads. Linear drivers require very few external components, integrate most of the fault/diagnostic features, are easy to pass EMI/EMC and are lower cost.

TI offers a family of single channel linear LED drivers – TPS9261x-Q1 family of devices supports various degrees of fault detection and reporting features. These devices are highly suitable for small load like DRL, position lamps, turn indicators and rear lamps in two wheelers. TPS92612-Q1 is a simple device without any diagnostics and more useful for interior lighting applications.

For 4 wheeler rear lamps, number of LEDs is generally high as compared to 2 wheelers and hence designers will require devices with more number of channels. TI’s TPS92630-Q1 (3 channel, 150mA/channel) and TPS92638-Q1 (8 channel, 70mA/channel) are most popular in this space.

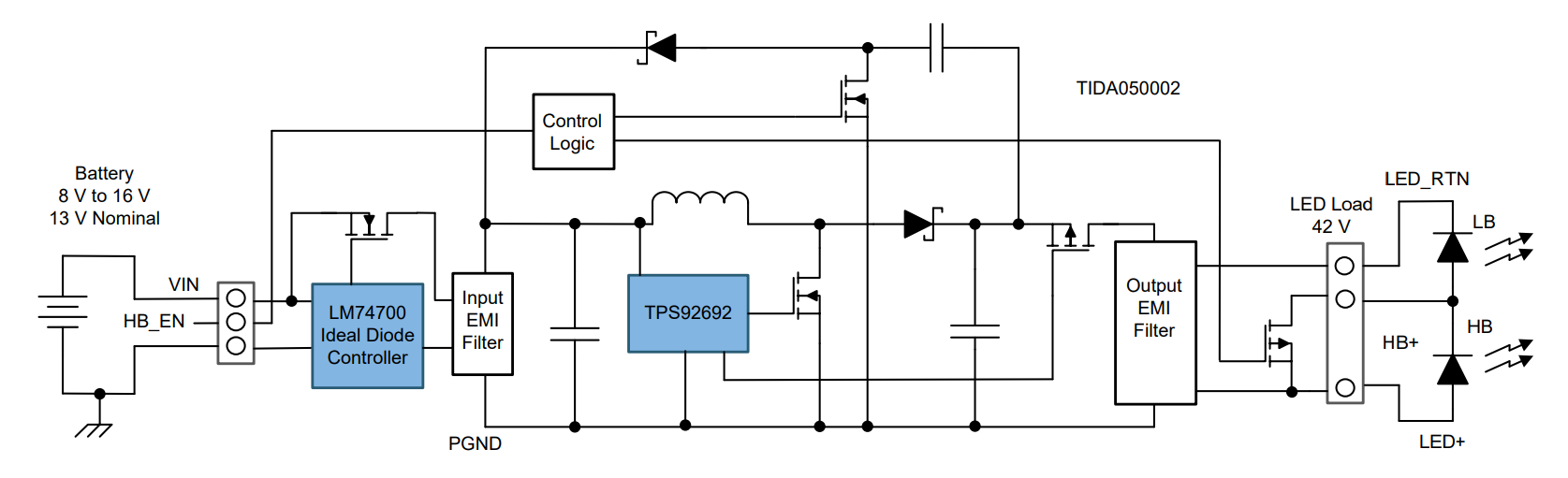

Although linear LED drivers are a designer’s first choice due to overall simplicity of the design, it is limited by total power dissipation handling capacity when input voltage is high and reduced intensity, when input voltage is low. For example, full LED headlamp generally use large number of high power LEDs which require a current source with about 1A output. Implementing a linear solution is almost impossible for such requirements, because it would produce a lot of heat when battery voltage is above nominal level of 12V. Also, during low voltage condition linear driver will not be able to regulate current through large number of LEDs connected in series. To address both these challenges, TI’s TPS92692-Q1 multi-topology LED driver is most suitable and popular amongst circuit designers.

TPS92692-Q1 can be used in boost, boost to battery (also called as buck-boost) and SEPIC topology. This device offers very good current regulation accuracy over temperature, analog/PWM/internal analog-to-PWM dimming options, spread spectrum frequency modulation for improved EMI/EMC and rail to rail current sense amplifier. It also provides fault reporting and auto-recovery options in case of over-current, over voltage, output short to ground. In summary, TPS92692-Q1 can be used in boost mode when output voltage (of a LED string) is higher than maximum input voltage. And it can be used in boost to battery mode, when output voltage (of a LED string) is between minimum and maximum input voltage. Note that, in boost to battery mode, none of the ends of an LED string isgrounded. In some cases, where one end of LED string needs to be grounded, SEPIC mode can be used.

There are some cases, for example two wheelers LED headlamp, where light intensity is allowed to dim at lower input voltage and hence a switching regulator in buck mode can be used for simplicity and reduced cost. For such requirements, TPS92515-Q1buck current regulator can be used which comes with an integrated MOSFET.

For vehicles with 24V battery, maximum input voltage can be as high as 60V during load dump (after TVS clamp). TPS92692-Q1 and TPS92515HV-Q1 are rated for maximum 65V operation; hence it can also be used for commercial vehicles with 24V battery. These devices are equally suitable for 48V electric vehicles. EVs with higher battery voltages generally have a 12V auxiliary battery and hence devices mentioned earlier are suitable.

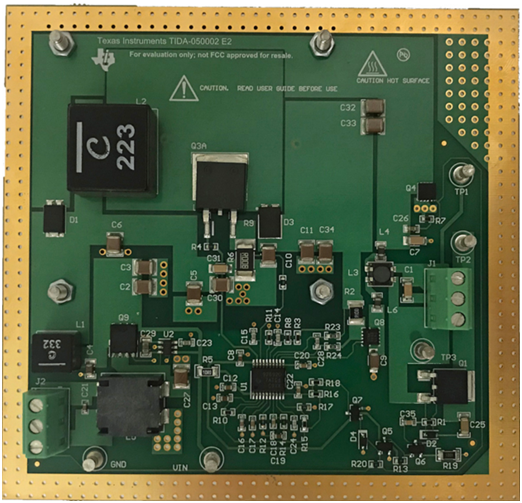

Currently in India, automotive market is slowly moving away from bulb based systems and towards LED based lighting system. Few years down the line, when all lighting loads will be LED based, more sophisticated and cost optimized drivers can be designed. This can be achieved by putting most of the electronic circuitry for multiple drivers on a common PCB for reduced cost. A very basic example of such cost optimized high beam and low beam LED driver for bike or car head lamp is TIDA-050002 reference design.

Figure 1. Cost optimized high beam and low beam LED driver design, TIDA-050002

Figure 2.TIDA-050002 block diagram

Most of the devices currently available in market have hardwired control; hence engineers need to design the hardware for each requirement separately. Also, very limited information is available from these devices about the fault occurring in the system.

However in future, more number of devices with digital control can be expected, which will provide detailed diagnostic information. Digital control will also allow designers to make a common hardware for multiple requirements. Just by changing few register settings in the MCU, same piece of hardware can be reused for multiple requirements. This will not only reduce hardware development cycle, but also simplify inventory management.

In more sophisticated and futuristic designs, even higher level of LED current control and diagnostics is expected at individual LED level. TI is market leader in such technology, which is popularly known as “Matrix manager LED drivers” required for adaptive headlamps. TI’s TPS92662-Q1 LED matrix manager device enables fully dynamic adaptive lighting solutions by providing individual pixel-level LED control. TI is committed to developing and deliveringsuch LED driver products which will meet and exceed current as well as future requirements of automotive industry.

Today, when we walk across the roads in city, they are fully lit with bright & white LED street lights which are either solar powered or grid powered. Few years down the line, all the vehicles on the roads will also be seen with LED based solutions for improved visibility and reduced emissions!!