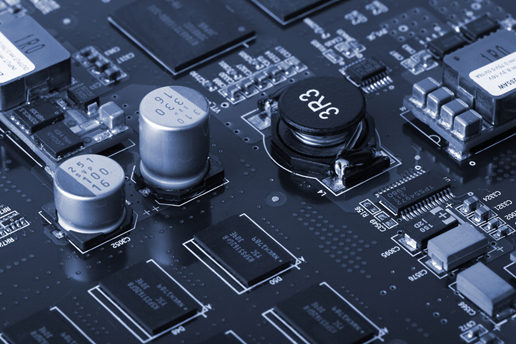

If anything, the PCB manufacturing process can turn out to be another rollercoaster journey of its own. When it comes to choosing among the dozens of PCB manufacturers in place, it can be very tough to know the right one. So, how do you go about selecting the proper PCB manufacturer without losing both your money and mind? First things first, here are some guidelines or essential questions to ask.

1. When exactly am I going to get my board back?

A simple answer to this question comes to that one common principle in life – how much are you willing to pay? While plenty of lower cost fab houses might try to convince you with a quick turnaround, in the real sense, reality can turn out to be somewhat different, often requiring a couple of weeks to build and ship your PCB.

Put in simple terms; you get what you pay for. Do you need your board delivered in a period of 3 -5 days? If so, then definitely, you need to plan your budget and put aside a little extra cash for such to happen.

2. Can you adequately source all the necessary materials for me?

There are high chances that you will want to save yourself plenty of hours that involve spreadsheet madness while attempting to avoid the hassles that accompany the management of Bills of Materials (BOM). Among other tricky things to handle regarding purchasing and supplies, BOM must be in the list.

So, to avoid all the challenges that accompany the above scenario, it is very crucial to check as to whether your potential PCB manufacturer has got in place an in-house purchasing department with the ability to handle the entire BOM for you as you sit down and relax or mind other income-generating businesses.

If you choose to go or instead pursue this route, rest assured of paying a little extra cash for the added luxury. But again, being given a chance to hand off your entire BOM and let a firm or somebody else do all the hard work for you in terms of sourcing and finding some hard-to-find parts are worth it.

3. Can you easily work with on the circuit board specifications?

Amongst all the possible questions that you may ask, this one is arguably super important. When it comes to PCB manufacturing, this question is ideal to ask, especially for low-cost vendors who have the habit of limiting the amount of data that they are willing to accept regarding the specifications of your board.

If you fail to ask such an important question, there are high chances of your chosen PCB manufacturer building your board to their standard set of guidelines and tolerance, which might fail to work in the long run. Be sure that your selected manufacturer can expertly handle your entire supplementary documentation such as:

- Your Layer Stackup– this will include any special copper material needs that are basic for the design of your PCB

- Your Drilling Table – this will outline the size and number of every drill hole that will go into the manufacture of your plastic control board (PCB).

Let your PCB manufacturer know about every drill hole that’s on your board and also be sure that you include any other miscellaneous specs that you may find it necessary to include such as plating requirements and the thickness of the copper material among others.

4. Where do they source board materials?

Is your potential PCB manufacturer just choosing or rather only using materials sourced from the cheapest supplier in the market? Much worse, is the firm just going for those materials that are readily available in the market? If this is the case, then you may have to take a step back.

If your PCB manufacturer purchases their materials in bulk from any vendor, expect some aspects of quality and consistency to vary between each design that you make from them significantly. Additionally, your board may likely need to meet certain specific regulations regarding the use of certain hazardous materials used in PCB manufacturing.

To be on the safe side, you need to make sure that your PCB manufacturer uses materials that meet several requirements such as those stipulated by the Restriction of Hazardous Substances (RoHS), Registration, and Evaluation and Authorization of Chemicals (REACH) among others depending on your location.

5. You are experienced and going to test my board, right?

When you are in the market for a technological manufacturer, it’s vital that you look for an experienced one with lots of years in the industry. Even if you find a skilled manufacturer, going for the one who has been in the industry for long is crucial.

A PCB manufacturer with extensive experience in the industry means that they comprehend the ins and outs of the entire process and can quickly adapt to emerging or advancing technologies without a lot of difficulties from their end. Besides, make sure that you choose a specialist who tests your PCB first before shipment.

Did you receive your PCB board and now it doesn’t function as desired? Sadly, a barebones PCB manufacturer won’t care as such, and you’ll be on the receiving end with a box full of coaster for your water glasses. Ensure that you have a healthy working relationship with a firm ready to offer you dedicated engineering support.

That way, rest assured of being able to detect any mistakes that may be in your layout way long before it eats your entire wallet with a couple of expensive connectivity tests. Quality control is arguably your last line of defense when it comes to preventing a faulty PCB board, and a firm that promises you such is essential.

Why is WellPCB the best choice?

When you finally decide to settle for a manufacturer, OUR PCB is a great option and preferred by many due to our diligence and accuracy in our designs. We take pride in ensuring that we strictly adhere to each detail provided by our customers on their design of the PCB.

While most PCB designers flood China for cheap circuit boards, they mostly overlook the quality that they get. It is something that OUR PCB takes serious and ensures that our clients get affordable PCBs for their electronics while still ensuring that the quality is uncompromised.

Our services

When it comes to PCB services, we cover almost everything related to PCB manufacture. In order to break it, our services will facilitate you from the designing stage until you receive your final product.

OUR PCB deals with manufacturing of basic and complex designs of printed circuit boards. We also assist our customers to come up with designs that will work great for their electronic device that they envision.

We also do PCB prototyping where we can work on a specific model that our customers might have in mind or as well offer great designs on possible PCB layouts that the customers can use. We can then create a prototype and manufacture more models later depending on the wishes of the customer.

Our great sales team will always be available to work with you and ensure that you have a seamless and comfortable experience from us.

Conclusion

The manufacture of your PCB of choice should not come as a very difficult moment for your business or invention. Rather, just some basic facts that you need to clear up with your PCB manufacturer should be the top priorities for you. How they handle their manufacture and how consistent their products are should be among the top queries for you.

If you would like more information or would like to order our services, please contact us to get the help you need. Act now and get exclusive offers.