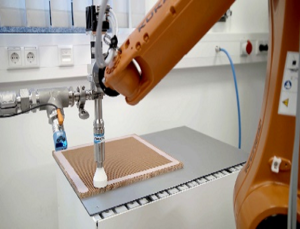

An example of honeycomb potting

Since its foundation in 1997, ViscoTec has stood for automated and precise dispensing technology in a wide range of sectors and industries, and for several now also in the special field of aerospace. Why is this area so special and what are the challenges here?

Further information can be found in the text below and in the video interview with Simon Widderich, Business Development Aerospace at ViscoTec: https://youtu.be/nA-UyP60KHc

Although ViscoTec has been established for 23 years, it was not until a few years ago that the focus turned to aerospace. This is due to the fact that the degree of automation in the production of aircraft is lower than one might expect. Although every aircraft today is a modern engineering feat of technology, many of the manufacturing processes to produce one still take place manually. One of the reasons for this is the number of components needed, which is much smaller than in the automotive industry, for example. Another reason is the complexity of the processes. There are certain material properties that pose many challenges, particularly in the production stages where fluids have to be applied.

Challenging material properties

Here we take a look at potting materials: These are epoxy resins that are used, for example, to fill in sandwich structures. They are intended to provide stability and stiffness with the least possible increase in weight. The constituent chemicals and components that enable the materials to meet performance characteristics also produce a material that is highly viscous (pasty) and favourable for manual process application. It is precisely this property that makes automation difficult nowadays. The more viscous a material is, the more difficult it is to process automatically

Requirements for dispensing materials

One of many requirements for the materials is to have the lowest possible density. This is because every gram of weight in, and on the aircraft leads to higher fuel consumption in the air, and that, in turn, leads to higher costs. To achieve the desired low density, hollow spheres are added to the materials. These consist either of glass or plastic and are extremely light. The hollow spheres have extremely sensitive properties and can be destroyed by excessive stress, which in turn would result in an increase in density.

Dispensing success with the endless piston principle

This is precisely where ViscoTec pump technology excels. With the progressive cavity pump, even very highly viscous materials (with up to 7,000,000 mPas) can be dispensed precisely and reliably. The handling of the material is very gentle. These features make it possible to automatically process even very high-viscosity potting materials from the container by means of an extraction system and to apply the material accurately and volumetrically via a dispensing system.

It is true that material manufacturers are now developing new materials that are easier to process. However, the basic properties, namely a relatively high viscosity and the filling with hollow spheres, remain unchanged. As a result, the ViscoTec endless piston principle can continue to display its decisive advantages. This is confirmed by numerous tests in the company’s own technical center, which demonstrate the ability to dispense these fluids and pastes. And there is more: “Our customers not only want to see the pure dispensability of the material in advance, but also the entire material application process. We have therefore equipped our premises with the appropriate equipment, such as axis systems and robots to meet this demand,” says Simon Widderich, Business Development Aerospace at ViscoTec, describing the increasing demands in dispensing technology. “Especially in aviation – a very safety-conscious industry – it is important to exclude any risks in advance. And we want to provide our customers with the best possible support in this respect”.

Here you will find more information about dispensing applications in the aerospace industry.