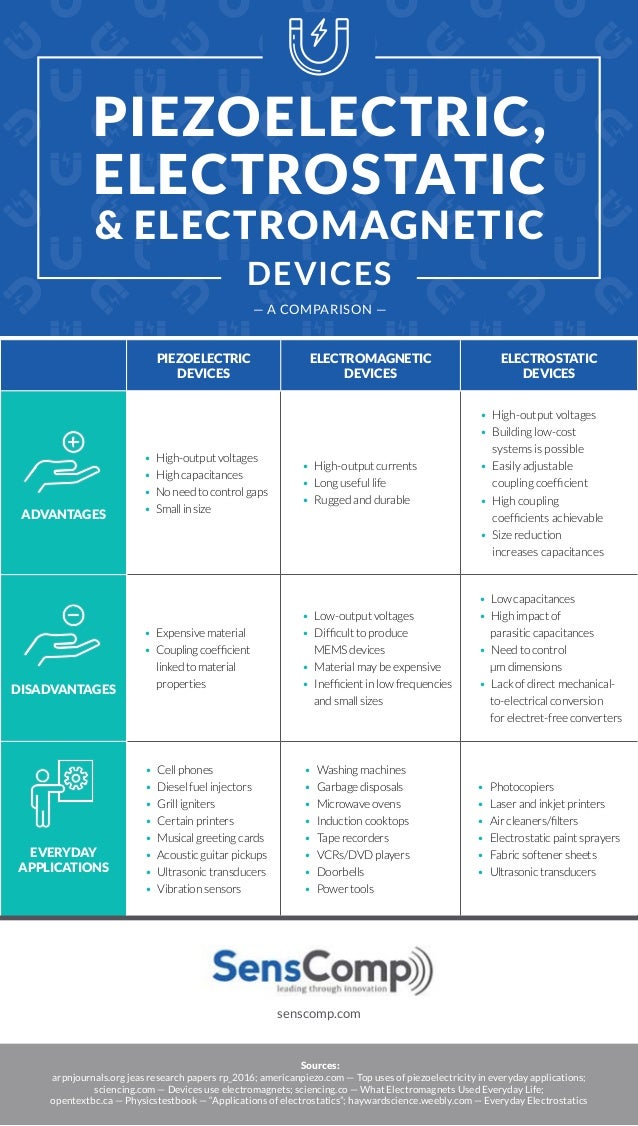

Which electronic device type delivers the biggest benefit for your use case? Are you best served by the rugged durability of electromagnetic options, the small-scale precision of piezoelectric solutions, or the emerging advantages of electrostatic sensors?

Here’s what you need to know about this electronic device trifecta — the potential positives, relevant negatives and ideal use cases.

Electromagnetic Solutions

Passing current through a wire wrapped around magnetic material creates a magnetic field — and vice versa. This makes electromagnets simple to operate, reliable to use and able to withstand significant physical stress. As a result, electromagnetic devices are often found in large appliances to provide reliable on/off operations over time.

Despite their attractiveness in specific applications, there’s a flipside to electromagnets: They’re difficult and costly to build.

This infographic was created by SensComp, a manufacturer of ultrasonic sensors

Piezoelectric Systems

Leveraging the properties of crystalline structures, piezoelectric systems create electricity by applying mechanical stress to deform crystal shapes and cause a charge imbalance. This makes them ideal for small-scale applications such as cellphones or vibration sensors, since they can be extremely small and require no gap control to manage output voltage.

Where piezoelectric promise begins to crack, though, is in cost and coupling efficiency. These devices are expensive to produce. Further, their efficacy is directly determined by material type.

Electrostatic Options

Potential energy forms the foundation of electrostatic devices. By altering the distance between parallel plate capacitors, it’s possible to increase voltage and capture the resulting output. With minimal energy loss under low- and high-mechanical acceleration, electrostatic options are ideal for electronic devices such as printers and photocopiers. They are now seeing significantly increased use as ultrasonic sensors.

There are limits to electrostatic potential — including low capacitances and the need for micrometer manufacturing control to better ensure devices operate efficiently.

Discover more about the electronic device differential with our comprehensive comparison of electromagnetic, piezoelectric and electrostatic devices.

Author bio: Margaret Bezerko is President of SensComp, a world leader in ultrasonic sensors. She has 18 years of experience in the industry and currently focuses on leading the company in second stage growth.