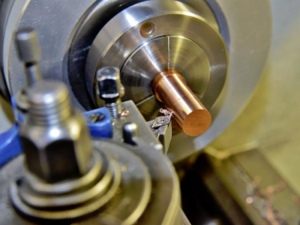

With the assistance of an engineering lathe, your most ambitious ideas and innovative projects can become a reality. The first challenge is choosing the right lathe and getting it at a good price.

With that in mind, here are some tips to follow as you sort through the various engineering lathe options that are on the table at the moment.

The benefits

A lathe is a flexible and effective piece of equipment for various purposes, whether you want to go all-out and complete more complex milling duties to make components for wearable tech from scratch or simply use it to turn materials and add the finishing touches to your latest creation.

Furthermore a modern engineering lathe can be surprisingly powerful and also compact, meaning that it can join your arsenal of workshop equipment without dominating too much space.

The purchasing options

The first dilemma you’ll face is not just where to buy your lathe, but whether you should choose a new model or take the second hand route.

For bleeding-edge features and post-sales support from the original manufacturer, new is the way to go. However, the affordability and quality of used engineering lathes available from the likes of Revelation Machinery make a compelling case for the second hand market being the better of the two, especially for first time buyers.

Whichever way you decide to go, be sure to do your research, compare prices and ensure that the seller is reputable to avoid disappointment and frustration.

The variables

There are a number of factors that should be used to determine the kind of lathe you choose. You need to consider how much space you have available to accommodate it, as well as how the size and capacity of the machine will impact the nature of the tasks that you can set it to achieve.

Another area in which lathes can differ from one another is operating speed. Single-speed lathes are better suited to more experienced users, while variable speed models maximize the overall versatility and will give beginners a chance to develop their skills.

The accessories

Buying a lathe is just the beginning, as you also need to think about the kind of tooling that is available and the other accessories which are compatible with it to work out if it is the best option for your requirements.

This is also where the new vs used debate returns to relevance, as finding accessories and components for older machines may not be as easy, although it should also be comparatively inexpensive and may even give you more choice, depending on the make and model of the lathe in question.

The build quality

Last of all, pay attention to the build quality of the lathe, as you will want a sturdy model that is predominantly constructed from steel or iron. This is not just about durability but also about stability during operation.

Weigh up all of these factors and work out what lathe will make most sense for your needs prior to beginning your buying journey and you should be set for satisfaction.