The Article explores the environmental sensing, space saving sensors which also offer low power consumption, and long life span for Industrial Internet of Things (IIoT) solutions.

People understand the impact of our environment on our surroundings and us more than ever before. For example, we are acutely aware of the air quality in our immediate vicinity due to working from home in sometimes small rooms. In such cases, carbon dioxide (CO2) sensors can provide guidance as to when to open a door or window to avoid headaches, impaired mental function, and lethargy.

Industrial processes, especially the burning of fossil fuels, release damaging gases and particulate matter (PM) into the atmosphere. Studies show that such gases are of particular concern to those with lung conditions or other long-term ailments. To combat this, accurate measurements are necessary to help define a plan of action to combat the issues and assess the results of countermeasures.

In recent years, semiconductor manufacturers have made significant advances in measurement technology, with improving capabilities in sensing volatile organic compounds (VOC), particulate matter, gases, relative humidity, and temperature. Furthermore, such sensors are tiny, have exceptionally low power consumption, and have a long life span. This makes them ideal for embedding into robust Industrial Internet of Things (IIoT) solutions.

Monitoring Nitrogen Dioxide and Ozone

The World Health Organization (WHO) differentiates between gases emitted, such as nitrogen dioxide (NO2), and those generated by chemical reactions, such as ozone (O3). NO2 can cause certain respiratory diseases and is prevalent in higher concentrations where combustion engines are in use. O3 forms naturally in the atmosphere and protects us from harmful UV rays. However, it is being measured in increased quantities closer to the ground, posing a risk to the young, elderly, and those with respiratory problems.

Providing a smooth path to measuring such gases is the Mikroe Air Quality 8 Click featuring a Renesas ZMOD4510 pre-calibrated digital sensor (Figure 1). Designed for indoor and outdoor operation, the Quality 8 Click board interfaces with host microcontrollers (MCU) via its I2C interface at 3.3V. Naturally, the board interfaces with the mikroBUS™ socket available on Mikroe development boards and is fully supported by the mikroSDK library.

Figure 1: The Mikroe Air Quality 8 Click detects both NO2 and ozone while drawing less than 23 mW. The board is naturally fully supported by the mikroSDK. (Source: Mouser Electronics)

The ZMOD4510 utilizes a silicon-based micro-electromechanical system (MEMS) coupled with a heater. Its signal conditioning circuit monitors a chemiresistor, converting the measurements to digital values. Drawing less than 23mW of power in continuous operation, it can detect in the parts-per-billion (ppb) range. Ideal for generating Air Quality Index (AQI) and ozone measurements, it is suited to environments with a relative humidity (RH) between 5 and 90%, and temperatures from -20°C to 50°C.

Keeping a Tab on Air Pressure and Temperature

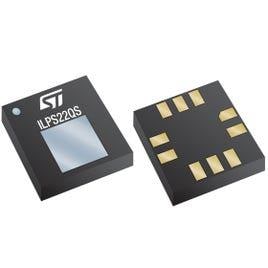

Air pressure sensors can be used to detect when smart air filters have reached the end of their life. They are also integrated into barometers to monitor weather conditions. Because temperature sensing is a relatively simple type of measurement, air pressure sensors often include temperature and other sensing options in a single package. This is the case with the STMicroelectronics ILPS22QS dual full-scale, absolute digital output barometer (Figure 2).

Figure 2: The ILPS22QS supports absolute barometric sensing, but can also measure temperature and operate as a user interface. (Source: Mouser Electronics)

Available in a microscopic, 10-pin HLGA, 2 × 2 × 0.73mm package, it can make absolute measurements from 260 to 1260 or 4060hPA, depending on the operational mode. Complete with temperature compensation, it delivers 24-bit output data between one and 200 times per second, supporting SPI, I2C, and MIPI I3CSM. The operational supply voltage is 1.7 to 3.6V, and its first-in, first-out (FIFO) buffer can store up to 128 measurements.

Its integrated analog hub switches between barometer, temperature, and two additional analog inputs. These inputs can be used as an STMicroelectronics’ Qvar electrostatic sensor. By implementing suitable electrodes, capabilities such as water leak detection or user interfaces, such as tapping, pressing, and swiping, are possible. By focusing solely on pressure measurements, current consumption can be as low as 1.8µA.

Sensor Playground for IIoT Applications

Innovation requires time to evaluate the actual performance and limitations of available technology. Luckily, sensor nodes, such as the STMicroelectronics STWIN SensorTile Wireless Industrial Node, ease the proof-of-concept development phase. It integrates no less than nine sensing technologies, ranging from gyros and motion sensors to magnetometers and vibration, together with a powerful STM32L4R9ZIJ6 ultra-low-power MCU (Figure 3). The kit also comes with a Li-Po battery, STLink-V3Mini debugger/programmer, and a protective plastic case.

Figure 3: The STWIN SensorTile integrates nine sensor technologies, Bluetooth, and RS485 connectivity. Wi-Fi and LTE cellular are supported with expansion boards. (Source: Mouser Electronics)

Connectivity is provided for Bluetooth (Low Energy) and RS485, while wireless interfaces are supported using optional Wi-Fi and LTE cellular expansion boards. Together with its optimized software libraries, it is easy to integrate into cloud-based monitoring solutions to display measurements and event detections in a suitably prepared dashboard.

Regardless of your environmental sensing challenge for industrial systems and IIoT, take a look at the wide array of sensing technology Mouser has to offer, or get in touch if you require support.

Source: Mouser Electronics