The complexity of your prototype design will determine whether it will be easy or difficult for you to build a product sample based on it. Complex designs will carry complicated design requirements that will add to the time completion estimate and costs of your prototyping project.

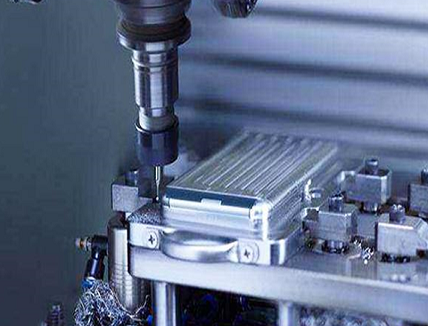

CNC Prototyping

How does design complexity affect CNC prototyping costs and feasibility? Let’s take a look at the most important points about design complexity vs. the costs of prototyping and its manufacturing feasibility.

- Complex Design Will Require the Use of More CNC Machine Types

Completing a CNC prototyping project will often require the manufacturers to use multiple CNC machine types. This is because one CNC machine type will not always be compatible with all design blueprints. With the simpler designs, it’s possible to use only the CNC milling equipment to complete it. However, for more complex designs, more than one CNC machine type will be needed.

Complex design will require you to use multiple CNC machines, because you might need to use various kinds of machining tools to complete one prototype based on that complex design. Using the plasma cutter tools, the EDM machine, grinder, turner, and many other equipment might be necessary. The more CNC machines you need to use, the more expensive the production process will be and the less feasible it will be for you to produce the prototype.

- Complex Design Might be Incompatible with Your CNC Equipment

Another problem with complex design is the incompatibility between the design blueprint and your CNC equipment. Unless you are creating your design by configuring it to be compatible with your specific CNC machine equipment, you might be out of luck when trying to implement your complex design in your CNC prototyping process. This compatibility issue might include the inability for you to add certain features from your design blueprint to the actual prototype or sample product.

When this problem happens, you will either need to change the design to make it compatible with your CNC equipment or use more equipment that can handle the prototype creation that follows your design blueprint. Both options will cost you more money to do and might not be feasible, especially if you are on a tight deadline.

- More Design Complexity Requires More Work to Complete

Creating a complex design for your prototype or product sample is not just something that you can do in a few hours. The design phase itself might take days or weeks to complete. You must think about every nook and cranny of your prototype or product design and the features to add. Also, it will take a highly skillful CAD designer to help you make a complex design for your prototype or product sample.

The design phase will require more time and more money to complete. Also, the manufacturing process will take even more time, money, and resources to complete your prototype or product sample based on your complex design.

- The Complexity in Prototype Design Might Produce Unnecessary Features

The more complex your prototype design, the more features you will add to it. However, did you stop right there to ask whether the additional features are necessary? Sometimes, simplicity in design is better than complexity in design, and more features don’t mean better for your product sample.

In fact, unnecessary features can only create bad user experience and give a “messy” outlook for your prototype or product sample. For instance, if you are creating a medical device prototype, the unnecessary features might only make it difficult for the patients to use the device or utilize it to help treat their health conditions. Not only that, adding these unnecessary features might cost more money in your production and might not be feasible at all for your bottom line.

- Complex Internal Design Will Be More Difficult to Implement

Do you need to add some internal features within the prototype body, which require deep hole drilling and other difficult implementations? This is another problem with design complexity that you need to keep in mind. While implementing these types of internal features might still be possible, it will be more difficult to implement in your production process, especially if you are using the rapid manufacturing method.

To implement these types of in-depth features around your internal prototype components, you will need to spend more time, more skills, more equipment, and more resources to complete them. It will surely add to the final budget for your prototype production, while at the same time, it might not be feasible for you to implement them.

- Simpler Prototype Design is Always Easier to Make and Cheaper to Produce

Sometimes, rather than focusing on creating a more complex prototype, it’s best for you to simplify your prototype design for the best result. Simplifying your design doesn’t mean scrapping your current prototype design and reducing it to the bare minimum. Instead, you are trying to make your complex design even simpler by changing various design layouts that might contribute to its intricacy and complexity.

A simpler prototype design will always be easier to make and cheaper to produce. So, the feasibility is always better for you when you use a simpler design instead of a more complex one.

- Simpler Prototype Design Requires Fewer CNC Machines and Resources to Make

Again, simpler prototype design will also require fewer CNC machines and resources to make, unlike the complex design that might require you to use various CNC machines. With simpler design, you might only need to use the CNC milling equipment along with the grinding machine to get it done.

The manufacturing process will also be much faster to complete, even when you use several CNC machines to complete your prototyping project.

Conclusion – Design Complexity vs. Feasibility and Costs of Production

Design complexity in your prototype will always affect your prototyping costs and feasibility, and it is something that any company needs to consider before sending their design blueprint to the CNC prototype service provider. It’s always ideal to make your design blueprint as simple as possible by eliminating or simplifying any intricate or complex geometry in your design.

TEAM Rapid offers a complete prototyping service for any company or brand that needs to get their prototypes done with the best quality result. Our factory in China can handle both small and big prototyping projects based on your design requirements and within your appointed deadline.