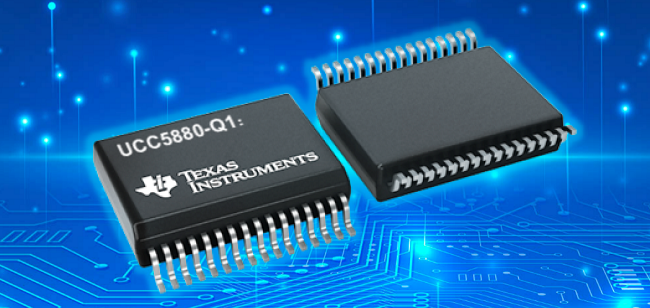

Electronics Media deep dive into TI’s recently launched gate driver that claims to provide up to 7 more miles of EV driving range per battery charge. In a recent Q and A with Wenjia Liu, Product Line Manager for High-Power Drivers from Texas Instruments explains how Safety-compliant and highly integrated UCC5880-Q1 isolated gate driver, offers the key to designing more efficient traction inverters while maximizing your EV’s range.

Electronics Media: The significance of the UCC5880-Q1 isolated gate driver in optimizing the efficiency and reliability of traction inverters in EVs.

Wenjia Liu: The UCC5880-Q1 isolated gate driver is a 20-A SiC gate driver that has advanced protection features for traction inverters in automotive applications. Its gate-drive strength varies from 5 A to 20 A, and is variable through both a 4-MHz bidirectional Serial Peripheral Interface bus or three digital input pins. The digital input pins enable setting the gate driver current strength at power-on without having to use the SPI bus providing ease of use.

Designers can improve system efficiency with the UCC5880-Q1 isolated gate driver as much as 2% by minimizing SiC switching power losses, resulting in up to 7 more miles of EV driving range per battery charge. For an EV user who charges their vehicle three times per week, that could mean more than 1,000 additional miles per year.

Electronics Media: The key features of the UCC5880-Q1 isolated gate driver that enable engineers to increase power density, reduce design complexity, and achieve safety and performance goals.

Wenjia Liu

Dual output split driver with on-the-fly programmable drive strength

- ±15-A and ±5-A drive current outputs

- Digital input pins (GD*) for drive strength adjustment without SPI

- 3 resistor settings R1, R2, or R1||R2

- Integrated 4-A active Miller clamp or optional external drive for Miller clamp transistor

Internal and external supply under-voltage and over-voltage protection

Driver die temperature sensing and over temperature protection

Short-circuit protection:

- 75-ns response time to over-current event

- DESAT protection – selections up to 14 V

- Shunt resistor based over-current protection

- Configurable protection threshold values and blanking times

- Programmable soft turnoff (STO) and two-level soft turnoff (2STO) current

Integrated 10-bit ADC

- Power switch temperature, driver die temperature, DESAT pin voltage, VCC2 voltage, phase current, DC Link voltage

- Programmable digital comparators

Advanced VCE/VDS clamping circuit

Functional Safety-Compliant

- Developed for functional safety applications

- Documentation available to aid ISO 26262 system design up to ASIL D

Integrated diagnostics:

- Built in self-test (BIST) for protection comparators

- Gate threshold voltage measurement for power device health monitoring

- INP to transistor gate path integrity

- Internal clock monitoring

- Fault alarm and warning outputs (nFLT*)

- ISO communication data integrity check

Safety-related certifications:

- 5-kVRMS isolation for 1 minute per UL1577 (planned)

- Reinforced isolation 7070-VPK per DIN VDE 0884-11: 2017-01 (planned)

Electronics Media: The potential impact of the UCC5880-Q1’s real-time variable gate-drive strength on system efficiency and EV driving range.

Wenjia Liu: When using the UCC5880-Q1’s strong gate drive to reduce SiC switching losses, the efficiency gain can be quite significant, depending on the traction inverter’s power level. Designers can improve system efficiency with the UCC5880-Q1 isolated gate driver as much as 2% by minimizing SiC switching power losses, which is quite significant given that traction inverter efficiency is already 90+%. This can result in up to 7 more miles of EV driving range per battery charge, which can add up to over 1,000 miles per year for an EV user. Seven miles could mean the difference between a consumer reaching a charger versus getting stranded.

Electronics Media: The integration of safety features, SPI programmability, and advanced monitoring and protection capabilities in the UCC5880-Q1 isolated gate driver, and how they contribute to reducing design complexity and component costs.

Wenjia Liu: The UCC5880-Q1 device is an isolated, highly configurable adjustable slew-rate gate driver targeted to drive high power SiC MOSFETs and IGBTs in EV/HEV applications. Power transistor protections such as shunt resistor based over-current, overtemperature (PTC, NTC, or diode), and DESAT detection, including selectable soft turn-off or two-level soft turn-off during these faults. To further reduce the application size, the UCC5880-Q1 isolated gate driver integrates an active Miller clamp, and an active gate pull-down while the driver is unpowered. An integrated 10-bit ADC enables monitoring of up to 2 analog inputs, VCC2, DESAT, and the gate driver temperature for enhanced system management. Diagnostics and detection functions are integrated to simplify the design of ASIL compliant systems. The parameters and thresholds for these features are configurable using the SPI, which allows the device to be used with nearly any SiC MOSFET or IGBT.

Electronics Media: The role of the SiC EV Traction Inverter Reference Design in facilitating the development of more efficient traction inverter systems.

Wenjia Liu: Traction inverters are the main consumer of battery power in electric vehicles (EVs), with power levels reaching 150 kW or higher. The efficiency and performance of traction inverters directly impact an EV’s driving range on a single charge. Therefore, to build the next generation of these systems, the industry has widely adopted silicon carbide (SiC) field-effect transistors (FETs) to enable higher reliability, efficiency and power density. The TIDM-02014 reference design enables quick time-to-market as it can be adopted by OEMs and Tier1s alike for faster development of a highly efficient SiC 800V/300kW traction inverter for EVs as well as Industrial applications such as industrial transport, EVTOL, railways, elevators, and any other high power application using SiC FETs. On our TIDM-02014 product folder we have a support section where we provide guidance on how to upgrade Wolfspeed 300kW inverters with TI’s reference design.