As technology becomes increasingly intricate, pellicles assume an indispensable role in safeguarding delicate components. The task at hand is to customize pellicles for compatibility with smaller devices, novel lithography techniques, and emerging technologies. In this dynamic semiconductor landscape, pellicles not only enhance device quality and performance but also embark on an exciting journey of innovation and limitless potential for the future.

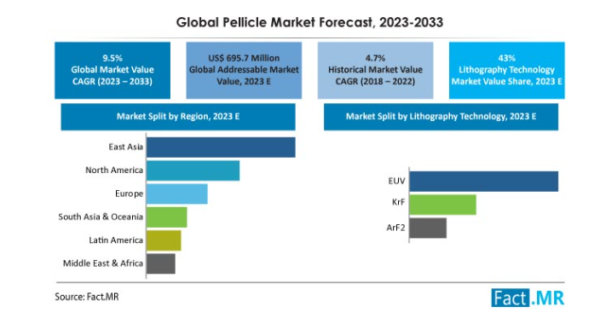

As per Fact.MR, the global pellicle market is expected to witness a CAGR of 9.5% to reach US $ 1,719.8 Mn by the end of 2033. factors such as significant investments in R&D, and technological advancements are expected to contribute to the high growth of the market.

What does the Evolution of the Pellicle Market look like in Europe and Asia Pacific?

Europe Market:

- In Europe, the pellicle market has undergone a transformative journey, closely aligned with the region’s substantial presence in semiconductor research, development, and production. As semiconductor nodes continue to shrink, thus pushing the boundaries of lithography, there has been an increasing demand for top-tier pellicles.

- Europe’s relentless pursuit of innovation and technological advancement has led to the creation of pioneering pellicle materials, groundbreaking designs, and cutting-edge manufacturing processes. Furthermore, Europe’s unwavering commitment to sustainability has prompted the exploration of ecologically responsible pellicle solutions.

- What truly sets the European pellicle market apart is the spirit of collaboration that exists among semiconductor manufacturers, research institutions, and material suppliers. This collaborative ecosystem has nurtured a dynamic environment that plays a pivotal role in shaping the future of pellicles within semiconductor manufacturing.

- Europe’s unwavering focus on technological innovation, combined with its dedication to sustainability, positions it as a formidable force in the development of pellicles. These advancements not only meet the specific semiconductor needs of the region but also resonate with global industry trends, making Europe a key player in the evolution of the pellicle market.

Asia Pacific Market:

- In the Asia Pacific region, the evolution of the pellicle market is closely tied to its dominant position in semiconductor production. Countries like South Korea, Japan, Taiwan, and China have been instrumental in driving advancements in chip manufacturing technologies.

- As semiconductor nodes reach new levels of miniaturization, the need for pellicles to protect photomasks from contaminants has become critical. Asia Pacific’s massive manufacturing infrastructure, investments in research and development, and strong industry partnerships have propelled the growth of the pellicle market. The region’s focus on mass production while maintaining high quality has resulted in the development of efficient and reliable pellicle solutions that cater to the semiconductor industry’s demanding requirements.

- As semiconductor technology progresses and miniaturizes, the demand for effective pellicles to safeguard sensitive photomasks increases. Asia Pacific’s dedication to technological advancement, robust manufacturing capabilities, and strategic investments positions it as a driving force in shaping the pellicle market’s trajectory within the semiconductor industry.

Overall, in both Europe and the Asia Pacific, the evolution of the pellicle market involves a blend of innovation, collaboration, technological progress, and responsiveness to the evolving needs of semiconductor manufacturing. These regions continue to contribute significantly to advancing the role of pellicles in ensuring the quality and precision of semiconductor devices.

Sustainability is an ongoing trend in the pellicle market:

Sustainability is an enduring and transformative force within the pellicle market, mirroring global industries’ commitment to environmentally responsible practices. This far-reaching trend encompasses multiple facets:

Material Innovation: Sustainable materials are gaining momentum, compelling manufacturers to explore alternatives like bio-based polymers and recyclable options. These choices align with the goal of reducing environmental impact and considering product lifecycles. Additionally, sustainability-driven manufacturing practices are becoming increasingly prevalent, with companies optimizing energy consumption, adopting clean technologies, and enhancing resource efficiency to minimize their ecological footprint.

Lifecycle Approach: The adoption of circular economy principles is shaping pellicle design and manufacturing. There’s a growing emphasis on creating products that can be easily disassembled, reused, or recycled, thereby minimizing waste generation.

Regulatory Compliance: Stringent environmental regulations mandate sustainable approaches. Manufacturers must ensure compliance with these rules to maintain market access and uphold ethical standards.

Customer Preferences: Environmentally conscious customers, including semiconductor manufacturers, are placing a premium on suppliers that integrate sustainability into their operations. This demand compels companies to demonstrate eco-friendly practices throughout their supply chains.

Innovation Pathways: Sustainability requirements serve as catalysts for innovation. Manufacturers are exploring novel solutions, such as water-based coatings and energy-efficient processes, to reduce their environmental impact.

Long-Term Value: Sustainable practices offer enduring benefits. These range from reduced operational costs through efficient resource utilization to improved brand reputation and market differentiation. The value of sustainability is multifaceted.

Collaborative Endeavors: Addressing sustainability challenges necessitates collective action. Industry partnerships, knowledge-sharing initiatives, and collaborative research expedite the adoption of environmentally responsible practices.

Reducing the Production Cost of Pellicles in Europe

The pellicle market in Europe faces various challenges stemming from high production costs, which ultimately restrict semiconductor manufacturers’ consumption. To alleviate these cost pressures, several strategic measures can be contemplated:

Material Selection and Sourcing: Thoroughly assess diverse pellicle materials to identify cost-effective options without compromising quality. Collaborate closely with suppliers to negotiate favorable pricing for bulk purchases and explore alternative sourcing channels.

Efficient Manufacturing Processes: Streamline manufacturing workflows to minimize waste, reduce downtime, and enhance overall efficiency. Embrace lean manufacturing principles and continuous improvement methodologies to identify bottlenecks and optimize processes.

Automation and Technology: Invest in automation and advanced manufacturing technologies to bolster productivity and reduce labor costs. Automation aids in precision manufacturing, minimizing errors, and increasing production throughput.

Energy Efficiency: Scrutinize energy consumption during manufacturing, pinpointing opportunities for optimization. This may involve optimizing equipment usage, upgrading to energy-efficient machinery, and implementing energy-conserving practices.

Supply Chain Optimization: Forge close collaborations with suppliers and partners to establish streamlined supply chains, thereby reducing lead times and curbing transportation costs. Implement just-in-time inventory practices to avoid the expenses associated with excess inventory.

Waste Reduction: Implement strategies to reduce material wastage during manufacturing. Consider recycling or repurposing waste materials whenever feasible.

Scale and Volume: Augment production volume to leverage economies of scale. Higher production quantities often lead to reduced unit costs due to optimized resource utilization.

Design for Manufacturability: Collaborate closely with design teams to ensure that pellicles are designed for straightforward and cost-effective manufacturing. Simplifying designs can mitigate production complexities and associated costs.

By implementing these strategies, the European pellicle market can mitigate the challenges posed by high production costs, fostering growth and sustainability in the semiconductor industry.