Laser technology is commonly used in a wide range of industrial and medical equipment, but also in devices found in almost every household. Fibre-optic networks, laser printers, laser thermometers, CD-ROM/DVD drives or bar code readers – all these devices are equipped with lasers. Usually, we do not wonder how a laser operates or why it has been mounted inside a device, but this topic is definitely worth consideration, as it is really interesting.

HOW DOES A LASER OPERATE?

The simplest, but also most imprecise answer to this question is to say that a laser shines. However, if the laser does shine, why is it that when you activate a laser pointer in a classroom or conference room, you can only see a single point on the screen, and the laser will not illuminate the entire room? The primary difference between an ordinary light bulb and a laser lies in how the light is focused. In the former, photons are scattered and move in all directions, which is why a light bulb can illuminate a dark room. In the case of a laser, it is quite the opposite, i.e. the light is concentrated at a single point to create a beam in which the photons move almost parallel to one another. This is why, when activating a laser, we can see only a small point illuminated by focused light.

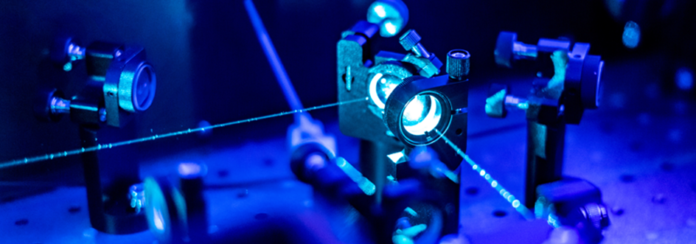

In order to visualise laser operation, imagine a small box covered on the inside with mirrors, in which several photons have been enclosed. These particles continuously travel around the box interior, bouncing off the mirrors. Each such impact releases a portion of energy being an exact copy of the photon. With each reflection, the number of light particles increases until it exceeds a critical point. Then, the photons pierce the wall of the box, creating a beam of light demonstrating very interesting properties.

Today’s lasers rely primarily on laser diodes based on the reflection-related phenomenon described above. Laser diodes are slightly similar to classic LEDs. However, there is an element similar to a resonance chamber for the released photons between the two areas of an N and P type semiconductor. It is a multi-layered “box” that can reflect light particles wholly or partially, so that they are eventually concentrated into a single beam.

LASERS IN ELECTRONIC ENGINEERING

Due to their properties, lasers are commonly employed in electronic applications. Plenty of devices and components operate on the basis of the phenomenon of multiple light wave reflection, the description of which is presented below:

Laser diodes

When we think of a laser, an ordinary laser diode usually comes to mind. Its design has already been described, but it is worth knowing that each such element is defined by a power parameter that determines the laser’s brightness rating. There are diodes with the power rating of 5 mW or reaching even 115,000 mW,. Here, it is very important to note that even low-power lasers can be hazardous to health. Under no circumstances can you emit a light beam directly into your eyes, as this can lead to irreversible damage to your eyesight.

When we think of a laser, an ordinary laser diode usually comes to mind. Its design has already been described, but it is worth knowing that each such element is defined by a power parameter that determines the laser’s brightness rating. There are diodes with the power rating of 5 mW or reaching even 115,000 mW,. Here, it is very important to note that even low-power lasers can be hazardous to health. Under no circumstances can you emit a light beam directly into your eyes, as this can lead to irreversible damage to your eyesight.

Laser diode: ADL-63102TL-3

Laser diodes usually emit red light, but infra-red designs are also available. They are usually enclosed in TO9, TO18 and TO56 housings designed for through-hole assembly (THT).

Laser modules

Laser module: FP-D-650-1-C-F

Apart from ordinary laser diodes, there are ready-made modules emitting laser beams. They are equipped with a diode plus additional electronic circuits to ensure adequate control. Laser modules are usually designed as cylindrical components in various sizes. In addition, attention should be paid to parameters such as power, supply voltage, colour and even the type of beam emitted. Thanks to the optical heads, laser modules emit a classic, straight light beam, but also beams in a form of ellipses, crosses and light lines. Such components are commonly used in industrial automation systems, in particular to create light barriers.

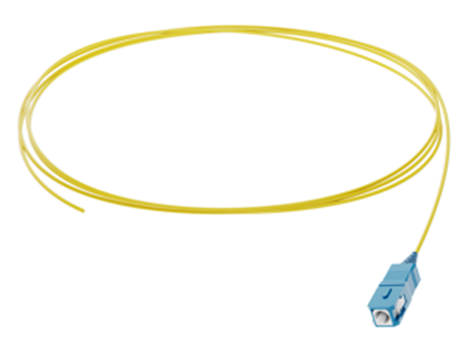

Fibre-optic cables

Fibre-optic cabling is also associated with the laser technology. It is only natural, as both these solutions are based on a similar principles of operation. A fibre-optic cable is a semi-transparent glass fibre structure facilitating the transmission of light acting as an information carrier. The light source carrying such information may consist of a laser diode (see above) or a classic LED (in some cases). While selecting a fibre-optic cable, note that its design is not completely universal, as it must be adapted to a specific transmission type.

Laser sensors

Distance sensor: HG-C1200-P

Laser distance sensors are devices whose operation is also based on a laser beam. These small-sized components are commonly used in the industrial sector as control elements for machine assemblies. Their principle of operation is quite straightforward. They emit a beam of light which, when reflected by a detected object, reaches a photoelectric element, which in turn emits a correct signal to a PLC, etc. Typically, a light transmitter and receiver are placed in a single housing, but there are also designs in which these components are separated. Such a solution makes it possible e.g. to detect an LCD module which, while moving on the production line, interrupts a laser beam emitted by the transmitter.

Laser sensors are characterised by a number of parameters, i.e. range, output set-up, operation modes, type of housing, frequency, tightness class or housing material. Each of these factors must be taken into account while selecting a correct sensor.

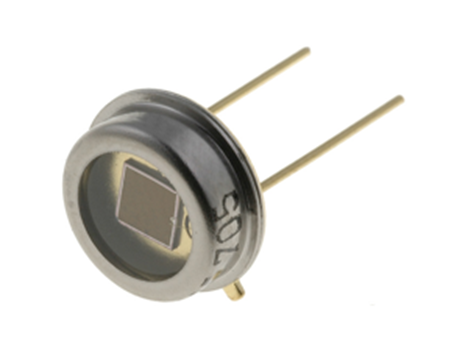

Optical components

Elements capable of detecting a light beam include photodiodes. These are small-sized semiconductor elements placed in housings with one transparent wall, allowing the laser light to fall directly on the silicon core of the element. Similarly to other diodes, a photodiode is based on a P-N junction which absorbs light emitted towards it. As a result, electrons move to the conduction band to increase current flowing through the element.

Photodiodes are designed both in through-hole assembly (THT) and surface-mounted (SMD) housings. A few parameters that are important for this diode type must be mentioned, i.e. sensitivity (wavelength in a point), angle of view, switching on/off speed and power.

Temperature meters

Pyrometer: FLK-62MAX

While discussing laser applications in electronic engineering, apart from electronic modules and components, one must also mention ready-made devices based on laser technology. These are, for example, laser pyrometers, i.e. contactless temperature meters. Their principle of operation is based on measuring the wavelength of infra-red radiation emitted by an object under investigation, the value of which is then converted into units of temperature. In addition, such devices often come with an additional red laser whose beam indicates a given measurement point.

Laser rangefinders

Laser rangefinders are other measuring devices based on the laser technology. They facilitate measuring a distance to an object being investigated, which makes them a popular solution in such fields as construction, land surveying or even maintenance. They emit a beam of light which, when reflected, returns and hits the optical component. Then, a rangefinder determines the distance based on the phase shift between the emitted and received light. Its operation somewhat resembles laser distance sensors.

Laser tachometers

A tachometer facilitates precise RPM measuring. The required value is measured in a contactless manner, and is also based on the laser technology. A tachometer operates similarly to the previously mentioned devices, i.e. a light beam hits a rotating element and partially returns after being reflected off the reflective element. This device counts the number of reflections constituting the basis for RPM value determination.

Bar code readers

A bar code reader is a popular device often used in shops, warehouses and manufacturing plants. Its operation is also based on the laser technology. Operation of each bar code reader is based on two components, i.e. a laser diode or a high-brightness LED and photodetector. A diode emits a beam of light which hits the scattering lens. When a bar code is placed within the scattered light path, the light is reflected, but only by the white parts of the code, as the dark lines absorb all the light. In reality, only the spaces between the bars are actually detected. The beam of light reflected and shredded by the bar code is transmitted to a photodetector which, together with the accompanying electronic circuits, converts the reflected light into electric pulses sent to a cash register computer, etc.

Bar code reader: QOLTEC-50860

Obviously, the above-mentioned devices and components are not all laser technology-related products available in the TME product catalogue. However, even this little segment of our product offering perfectly shows the versatility and a wide range of applications of this technology.