An electronic device comprises of a wide range of components. Can you name the most critical part? Yes, it is none other than a flexible PCB. Compact size and lightweight design allow flexible PCBs to connect various components.

With a wide range of methods available for assembling the components, choosing the right method may be a bit challenging. This blog will delve you into some efficient tips to enable efficient assembling and integration of flexible PCB assembly.

From the selection of materials to testing, following best industry practices will make sure that the final product meets the performance standards. Before moving further, it will be good to have a brief idea about flexible PCB boards.

What Does a Flexible PCB Imply?

A flexible PCB is a special type of circuit board that can be easily bent, rolled up, and folded. Unlike rigid PCB, it is highly flexible. The flexible base materials and conductive circuits included ensure exclusive techniques related to processing.

Because of excellent adaptability and flexibility, flexible PCBs can be easily designed in any shape and size. You can easily integrate them into compact electronic devices and connect various components.

After insights into flexible PCB, it is time to peep into some advantages of flexible PCB that include the following:

- Light-in weight

- Thin in dimension

- Can be wired easily in every direction

- Remarkable electrical performance

Even after having lots of benefits, flex PCBs are inclusive of certain limitations, like:

- Relatively high price

- Complexity results in lots of difficulties while designing

- Flexible PCBs are not suitable for higher scenarios

Now it is high time to peep into some amazing hacks related to assembling and integrating flexible PCBs.

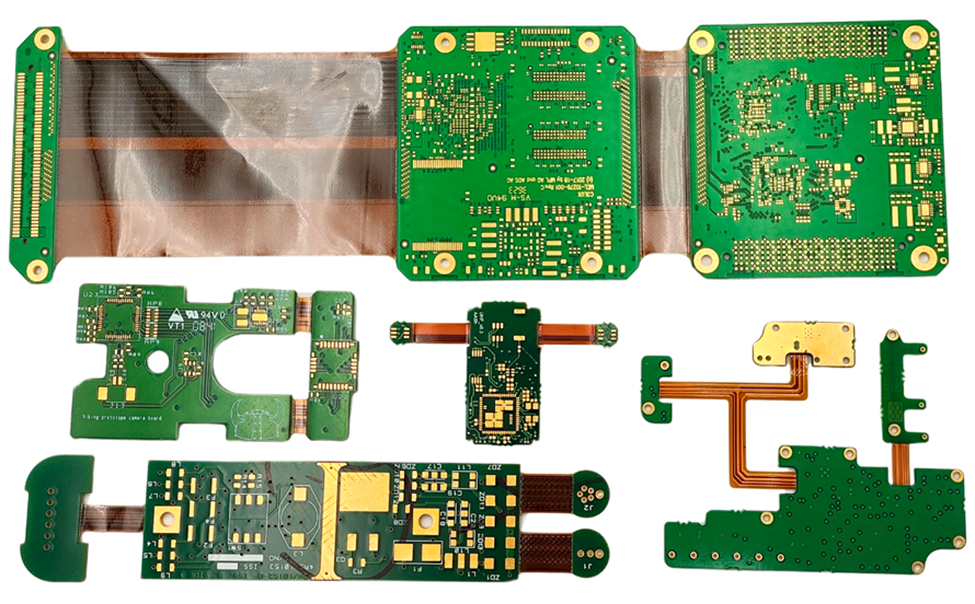

What are the Different Types of Flexible PCBs Available?

If you start browsing the market, then there will be a vast range of choices available. Based on size, structure configuration, and functionality; you can easily select the one that matches your choice.

In the case of flexible PCB, you will come across a limited number of choices. Lots of differences exist among each type based on the overall process of manufacturing. Some of the major types of flex PCBs available in the market are:

- Single-sided flexible PCB

- Double-sided flexible PCB

- Sculptured flex PCB

- Multi-layer flexible PCB

It will be wise to get an idea about the different types of flexible circuits available in the market. They are:

- Flex circuit – A flex circuit is manufactured using exclusively flexible and thin materials. Applications are much simpler and are similar to a single-layer circuit.

- Rigid flex – Rigid flex is constructed by using both rigid and flexible materials. Being a 3D interconnect, it can be easily bent and folded in any shape.

- High-density interconnect PCB – A high-density interconnect PCB characterizes a higher layer count, closer spaces, and dense wiring, and features fast connection.

Do you need to start with the process of carrying out PCB assembly? If yes, then it is high time to peep into the several tips that are as under……

What are Some Efficient Tips to Carry out with Flexible PCB Assembly and Integration?

To carry out the process of flexible PCB assembly process smoothly, there are some exclusive tips to follow. Below are those tips that you must consider from the start to the final stage:

- Identification of the right components – Firstly, to carry out the flexible PCB assembly, it is essential to identify the right type of components to be mounted. Simultaneously, you must look into details like part numbers, quantities, and reference designators.

- Removal of moisture properly – Installation of components containing moisture must be avoided. As flex circuits are inclusive of humidity-sensitive components, a certain level of dryness is required.

With the help of the baking process properly, it is possible to make the board free from moisture. The temperature to be set depends on the level of moisture available on the board.

- Making use of high-quality solder paste – Without the use of solder paste, carrying out the process of flex PCB assembly is difficult. In terms of operation, the components need to be mounted on the printed circuit board.

The application of solder paste can be done either manually or automatically. As the paste helps connect the electrical components on the circuit board, it must be branded.

- Component placement – At the time of mounting components in the PCB, it is essential to be careful. Whether it is done manually or automatically, you must ensure the proper location of every component.

With the flexible PCB assembly process, surface-mount technology and through-hole technology are some common methods. SMT is used in the case of two small components, whereas the THT method is useful if components are large.

- Heating the board properly – Soldering components in the PCB is the next step where each joint is soldered. This involves heating the board. At the time of carrying out this process, you must ensure that the temperature remains moderate.

Melting the solder paste helps in establishing a connection between components and PCBs. Too much heating may result in unnecessary destruction of the board.

- Carrying out the testing phase – The PCB assembly process is inclusive of detailed inspection and testing of every minute detail. Until the board meets performance standards, the testing goes on.

The process of testing helps in detecting defects found on the board. The inspection process can be carried out either with the help of automated system or manual visual inspection.

- Do not forget to box the final circuit – The final step involved in the flex PCB assembly process is sturdy packaging. Once every detail is found to be up to industry standards, the board is ready to be shipped.

During packing, it is advisable to use a sturdy and robust material. Also, proper labeling and boxing will prevent any misuse of the PCB manufactured. Proper packaging will ensure easy reaching of the board to the desired destination safely.

Keeping these vital tips into high consideration will lead to an efficient flexible PCB assembly and integration. Though it is a comprehensive process, if carried out with care, then the overall outcome can be as per industry standards.

Following some best practices will let in streamline assembling, thus reducing cost.