In power system design, safety doesn’t come as a box to tick. Instead, it’s engineered into every wire, enclosure, and insulation layer. Choosing between classes of power supply units (PSUs) is one of the most important things an engineer has to do. This choice greatly affects insulation strategy, grounding, compliance testing, and the system’s overall reliability.

The main distinction between Class I and Class II systems is how they safeguard users and insulate electrical equipment in case of a problem. If you know how to install these and how to install them correctly, you may avoid expensive design mistakes and ensure that systems pass certification on the first try.

Understanding Class I Power Supplies

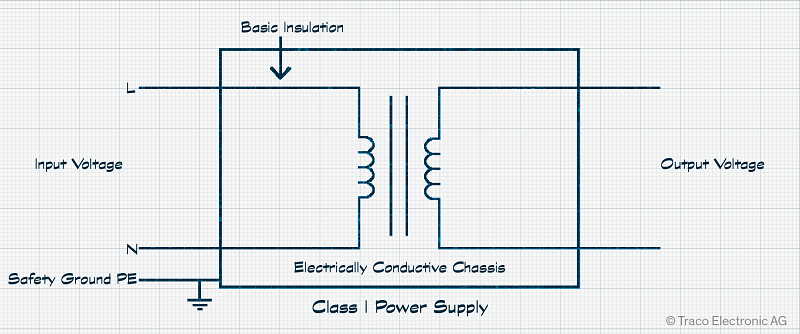

Class I power supplies rely on a two-level safety approach: basic insulation and a protective earth connection. The metal shell could constitute a shock hazard if the primary insulation between the live electronics and the chassis breaks. To prevent this scenario, the chassis is directly connected to the ground, which allows fault current to flow. Leaks can prompt a circuit breaker or GFI, protecting the user.

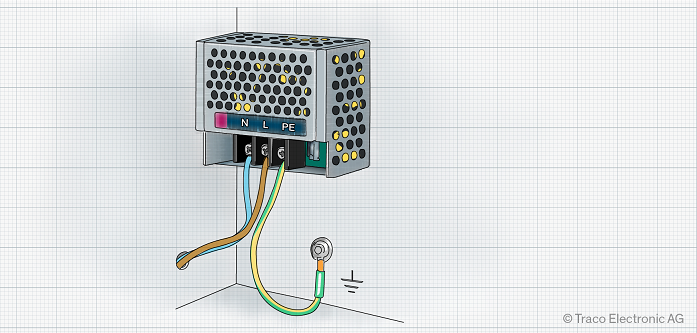

A Class I PSU usually comes in a metal case and gets power using a three-conductor input cable with live, neutral, and earth wires. This setup protects users from live wires that touch the case by using the grounding system.

Applications Where Class I Dominates

Industrial and professional settings employ Class I units. Their application benefits grounded metal enclosure systems, including control panels, server racks, and bench-top equipment. Grounding is incorporated into the system in these instances, not just for safety.

However, using protective earth depends on one crucial thing: the earth connection has to be safe. Many structures, especially those in older residential districts, don’t have adequate grounding. In hospital or domestic settings, where a single failure could have significant effects, the problem becomes a liability.

What Are Class II Power Supplies?

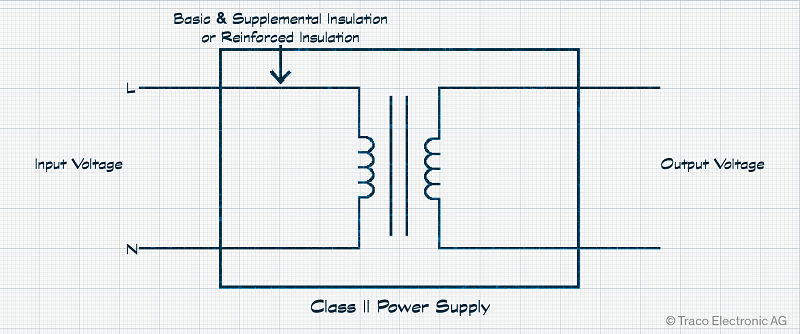

Class II power supplies take a different route to safety. Rather than grounding the enclosure, they eliminate the need for earth by using double or reinforced insulation. This method physically separates live circuitry from the user with multiple insulating barriers, enough that even a single failure won’t result in an electric shock.

A Class II PSU typically features a plastic housing or open-frame construction with no exposed conductive parts. The input cable includes only two conductors, live and neutral. Because there’s no earth pin, installation is simpler and safer in environments where a reliable ground can’t be guaranteed.

Why Class II is Preferred for Home and Medical Use

In home healthcare applications, safety standards such as IEC 60601-1-11 mandate using Class II power supplies. The reasoning is clear: a device that doesn’t rely on a building’s potentially unreliable ground system is inherently safer for vulnerable patients.

The same applies to phone chargers, laptop adapters, and many other consumer goods. An insulation-only protection method is simple and strong, making it suitable for these settings.

Installation Requirements: Matching Class to Method

Installing Class I Supplies

The earth connection must be physically secure and electrically continuous when installing a Class I power supply. Use proper torque when tightening screws, ensure that any paint or anodizing is removed from the contact area, and verify earth continuity during system testing. The PSU’s case must be bonded to the system chassis to preserve safety integrity in metal enclosures.

Failing to connect the protective earth or introducing high impedance through poor grounding can render the safety features ineffective.

Installing Class II Supplies

By contrast, Class II power supplies must remain completely isolated. There should be no connection to protective earth, and care must be taken to avoid inadvertent bonding through mounting screws, brackets, or other conductive paths. When mounting inside a metal enclosure, non-conductive spacers may be needed to preserve double insulation.

EMI mitigation may require a functional earth (not protected earth) for filtering. However, this functional ground must be carefully built to isolate from the protective earth to keep the PSU Class II compliant.

Compliance Considerations and Selection Tips

Selecting the Right PSU: What to Look For

Datasheets are dense, and certification wording varies, making choosing a PSU that matches class requirements difficult. However, the protection class must be identified first. The quickest way is to look for a clear label in the safety approvals section of the datasheet. Don’t assume the case material or connector tells you the class; check that the document explicitly states Class I or II and references the correct IEC or EN standards. This avoids confusion later when the design goes to compliance testing.

Confirm that the PSU includes a protective earth terminal for Class I systems and that its datasheet specifies compliance with Class I standards. The chassis must be grounded for wiring instructions in metallic enclosures.

For Class II systems, seek “double insulation” or “reinforced insulation.” Commonly, the global square-inside-a-square symbol is used to show this. Datasheets should confirm compliance with Class II or IEC safety standards, and no provision for connecting an earth wire should exist. Engineers should also review the connector drawings to confirm there is no PE pin, and check the mounting instructions to ensure the unit cannot be bonded to a grounded enclosure by accident. These simple checks keep the isolation strategy intact and ensure the build stays Class II compliant.

Installation conditions can also influence selection. For example, a Class II PSU may be preferred to simplify certification if the power supply is mounted in a plastic enclosure with no exposed metal. On the other hand, in a grounded metal enclosure where leakage current must be managed via earth, a Class I PSU may be more appropriate.

Compliance Checklist for Engineers

Many safety decisions are already locked in when a PSU reaches the integration phase. Engineers can make this process easier by asking:

- Is the PSU clearly labeled as Class I or Class II, and does it match the system’s protection class?

- For Class I, is the Earth ground path correctly connected and verified?

- For Class II, does the mounting method maintain double or reinforced insulation?

- Are the application’s leakage currents within acceptable limits (e.g., <70µA for touch current)?

- Does the PSU meet EMC standards for its target environment, and is a sufficient test margin built in?

Avoiding Common Mistakes

One of the most frequent errors in PSU integration is confusing UL Class 2 with IEC Class II. The former refers to current and voltage-limited outputs for wiring safety, while the latter deals with insulation and protection. They are not interchangeable.

Another pitfall is mixing protection schemes. For example, installing a Class II PSU inside a grounded metal housing without proper isolation can introduce unintended earth paths, defeating the insulation strategy. Conversely, omitting the earth connection in a Class I system compromises its safety entirely.

Summary

Class I and Class II PSUs represent two distinct philosophies in electrical safety. Class I protects users by grounding the system. In contrast, Class II protects users by using better insulation such that grounding isn’t even necessary.

The application, the material of the enclosure, and the environment all play a role in deciding which one to choose. How the PSU is fitted is just as crucial as the choice itself. Mistakes at this stage can make even the safest design useless.

Engineers need to know about these modifications and follow the datasheet instructions to comply. If you’re still not sure, get in touch with the company that makes your power supply. The first step to safety is understanding; the first line of defense is clarity.

Source: Traco Power