Panasonic Components Power GenAI Data Centers with Reliable 48VDC Infrastructure

Generative Artificial Intelligence (GenAI) is here to stay, and it is pushing data center power consumption ever higher. The cost of running a data center was already heavily driven by its electricity bill, so this surge in consumption has only led to an increased importance in energy efficiency for data center power management.

Continuous system uptime has also never been more essential as data centers attempt to secure revenue streams that exceed their running costs. Power systems are at the heart of this issue.

What hurdles arise when designing data center power systems with such high levels of efficiency and reliability? This blog outlines several key challenges and presents potential solutions as we enter the era of GenAI.

Ensuring Power Supply Reliability

The importance of power systems is hard to overstate. A whopping 52 percent of data system downtime can be attributed to power system outages. A common reason for these faults is that sudden surges in processing demand can cause hardware clusters to draw more power than can be supplied. The unintentional drop in supply voltage as current draw increases then causes processors to shut down. With processing requests coming so frequently for GenAI, systems can become overwhelmed before power supply issues are even detected.

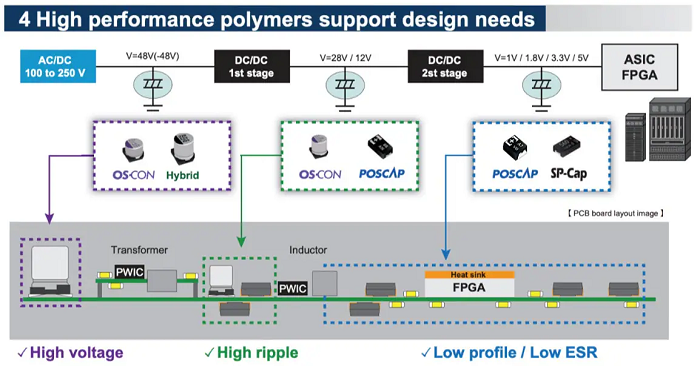

The key to preventing these dropouts is stabilizing the power supply to the processors, which can be done using capacitors suited for each stage of a 48VDC power supply, which is the new standard for AI-ready data centers. As shown in Figure 1, Panasonic offers multiple families of high-reliability, high-temperature polymer capacitors that support this industry-led shift.

Why 48V Is the New Standard

Resistive losses in a conductor scale quadratically with current, but modern data centers require increasingly higher currents to meet processing demands. Moving from a 12V bus to a 48V bus cuts the supply current for the same power by a factor of four. With lower current, resistive losses fall about 16 times lower, making higher-power systems more efficient.

The 48V standard allows systems to eliminate the later stages of down conversion associated with 12V, which reduces conversion losses to improve efficiency. Removing this power circuitry also creates more room for computing infrastructure, enabling designers to increase the density of server racks.

This shift towards a more efficient way of supplying power is highly relevant for applications like AI, edge computing, and hyperscale data centers. One estimate predicts AI will drive electricity demand to approximately 945 terawatt-hours (TWh) by 2030, more than doubling current numbers. These are just a few examples of why data center operators must achieve the greatest processing performance per watt possible to maximize the value of the services they provide.

The Role of Polymer Capacitors in 48V Systems

Reliable power supply is indispensable to maintaining system uptime. Capacitors are needed to maintain steady current supply to processing components in data centers. Sudden spikes in demand, driven by processing tasks, can result in voltage drops as power supplies become overwhelmed. If supply voltage deviates from the acceptable range, processors shut down.

Whether they are used in 48V DC/DC converters or voltage regulator modules (VRMs), polymer capacitors have advantages over traditional electrolytics in data center environments:

- Lower equivalent series resistance (ESR) reduces power loss and heat generation, boosting conversion efficiency while easing thermal management requirements.

- Stable capacitance over temperature and frequency offers predictable performance in unpredictable environments. One example is when a new task, and therefore power demand, is quickly diverted to systems at different temperatures based on surrounding workloads.

- Longer lifespan and reliability under high ripple currents support more robust DC/DC conversion. This prevents damage to VRMs and downstream components during power fluctuations.

Panasonic Polymer Capacitors: Ideal for Data Centers and More

Panasonic SP-Cap polymer aluminum capacitors are primarily used as input and output capacitors for DC/DC converters. The SP-Cap capacitors use a conductive polymer as their electrolyte material in a layered aluminum design. With their ultra-low ESR values and ability to withstand high reflow temperatures, SP-Cap capacitors are highly suited for data center deployments.

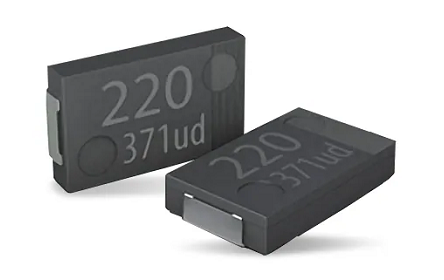

For DC/DC conversion and VRMs close to high-power processors, the SP-Cap capacitors offer high performance and reliability under constantly fluctuating loads. And their low-profile, surface-mount packages, shown in Figure 2, save board space as fewer components are required to meet capacitance needs.

The SP-Cap series can be divided into subfamilies serving specific performance requirements, such as high reliability, ultra-low ESR, and low profile. The series is not only fitting for data centers, but it also supports applications that include industrial equipment, drones, and communications infrastructure.

Across its different models, the SP-Cap series offers:

- Ultra-low ESR down to 3mΩ

- Options for -55°C to +135°C operation, with 5500 hours endurance at +135°C

- Low profile down to 1mm

- High ripple current capability up to 10.2Arms

- Voltage range of 2VDC to 35VDC

- Capacitance between 10μF to 820μF

Using Panasonic SP-Cap in Real-World Settings

SP-Cap devices offer distinct design advantages across several key markets, enabled by their well-engineered specifications. These specifications serve designers well in several notable applications:

- AI Servers: The SP-Cap’s large capacitance and reliability under fluctuating loads supports stable power delivery to CPUs, GPUs, and AI hardware accelerators in applications where on-demand processing requires sudden boosts to performance through additional current.

- Edge Computing: The compact nature of the SP-Cap devices supports reliable power in space- and resource-constrained designs where data is processed close to its source. Robust thermal performance is also useful for building fanless computing systems where thermal efficiency becomes essential.

- 5G Base Stations: With high reliability—a key feature of the SP-Cap series—these capacitors are well-suited to harsh deployments where system uptime is key to providing comprehensive network coverage for dependable communications.

A Reliable Path for Powering Modern Data Centers

As data centers adopt 48V power to support modern applications like generative AI, polymer capacitors ensure that power delivery is reliable and efficient in these thermally challenging environments. With its SP-Cap series, Panasonic offers low-ESR, high-capacitance solutions with small form factors to simultaneously increase efficiency and processing density, enabling greater revenue potential to offset data center running costs. For solutions across the full 48V power pipeline, Panasonic’s OS-CON and POSCAP series provide versatile polymer capacitor options to serve specific requirements at each stage of power conversion.

Source: Mouser blog