The electronics manufacturing boom facilitates reshoring and expansion, enabling specialized services like custom die-cutting and multilayer laminating across the country. The top-rated converting services for electronics manufacturing in the U.S. are particularly specialized, supporting clients from design to packaging.

Why The Electronics Manufacturing Industry Is Booming

The performance of the North American consumer electronics market has long been a reliable indicator of broader demand in adjacent industries. One research report places its compound annual growth rate at 4.67% from 2025 to 2033, during which it is projected to increase from $256.6 billion to $369.62 billion. This estimate shows the surge in demand.

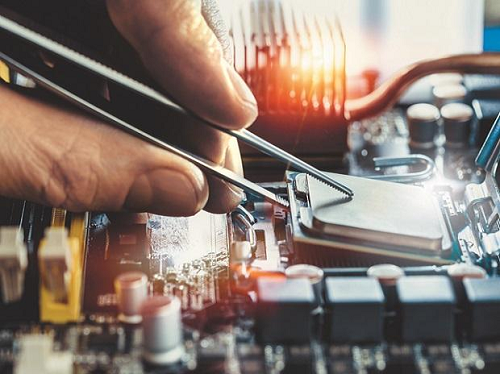

The industry’s growth stems from technical advances and innovative design trends, such as miniaturization. Manufacturers are investing in cutting-edge techniques and tools — and many are receiving government funding — so their capabilities are evolving.

America’s industrial policy push has triggered a manufacturing boom. Historically, manufacturing investments have been elevated. This means commercial manufacturers could receive trillions of dollars in federal grants, loans, guarantees and tax credits. The CHIPS and Science Act alone provides nearly $53 billion in direct government spending and a large, open-ended tax credit.

Aside from funding surges, geopolitical changes, the COVID-19 pandemic and tariff volatility have incentivized reshoring. More manufacturers are expanding their U.S. operations, diversifying their supply chains or producing more American-made products. These changes are accelerating lead times and driving growth in specialized services.

Top-Rated Electronics Manufacturing Converting Services

Electronics industry professionals seeking conversion services no longer have to look outside the U.S. for high-quality products at competitive prices. There are many excellent options for custom, American-made products at fair prices.

1. Advantage Converting

Since Advantage Converting has a 25,000-square-foot facility in the Bay Area with 5,000 square feet of climate-controlled ISO 7 and 8 clean rooms, it is uniquely positioned to provide the highest-quality products at the lowest possible cost. Its capabilities include custom die-cutting, precision slitting, multilayer laminating and rewinding.

While many companies can purchase and convert 3M products, only a select few have earned the distinction of 3M Preferred Converter. This designation demonstrates its ability to help industry professionals improve production quality and reduce production costs.

As a full-service company, its services cover design, packaging and everything in between. It maintains precision and consistency while producing goods at high volumes. Its in-house team handles engineering, material sourcing and custom tooling. It boasts the fastest turnaround times, a strict adherence to quality standards and exceptional customer service.

2. Custom Fabricating & Supplies

Wisconsin-based Custom Fabricating & Supplies is a testament to the industry’s impressive growth. It doubled in size within five years of its founding. Since then, it has moved four times to expand its fabrication and supply space. Most recently, it relocated to a 70,000-square-foot facility near Milwaukee and has established several satellite locations.

As a 3M Preferred Converter, it offers a large stock of adhesives, tapes, foams, rubbers and sponges across three U.S. locations. Customers can request specialty materials like magnets, fire-retardant paper or cardboard because it can work with nonstandard materials.

Its converting services cover die-cutting, adhesive laminating, slitting, zone coating, cutting, rewinding, printing and coating for nonmetallic materials in various diameters and thicknesses. It is so confident in its capabilities that it will modify prototypes at its expense if the original does not perform as promised.

3. Custom Converting Inc.

Custom Converting Inc. is based in California, with all of its products made in America. Its custom services include die-cutting, adhesive coating, laminating and sub-assembly. It also provides close tolerance slitting, in-line printing, punching, sheeting, multilayer laminating and packaging. Like other leading providers, it offers fast lead times and competitive rates.

Custom Converting Inc. is certified by the American System Register and the ANSI National Accreditation Board as a custom contract manufacturing and packaging service provider. Its facilities are ISO 9001:2015 and Food and Drug Administration compliant, demonstrating its adherence to quality control.

As a 3M Select Converter, it offers specialized material access, strong product knowledge and robust in-house conversion capabilities. While 3M Preferred is more prestigious, this designation is also impressive.

4. Precision Converting

Converting product manufacturer Precision Converting is a division of Hisco, an industrial supply and equipment supplier. It has dozens of branch locations across North America and manufacturing facilities located in California, Texas and Illinois. It features ISO 7 clean room manufacturing capabilities, enabling it to meet or exceed industry quality standards.

Since it has a comprehensive supplier network, it can source cork, sponge, papers, foils, films, pressure-sensitive adhesives and rubber. It has material experts on staff to answer any questions about specialty materials. Custom engineering is its specialty, allowing it to work with nonstandard materials.

Its converting capabilities include die-cutting, rewinding, packaging, laminating, sheeting, folding, slitting and unwinding. It can tailor some of these services to meet customers’ needs, accommodating everything from short runs to full-scale production. Whether they require a few products or millions of units, it can address their design, manufacturing and assembly needs.

Comparing Leading Electronics Contract Manufacturers

The top-rated electronics manufacturing converting services in the U.S. use industry-leading techniques, tools and expertise. They consistently meet or beat regulatory standards and many have the 3M Preferred Converter designation. While they have similar services, experience and clean room capabilities. However, even in a direct comparison, some stand out for superior quality.

| Manufacturing Company | Advantage Converting | CFS | CCI | Precision Converting |

| Industry Expertise | Three decades | Two decades | Four decades | Three decades |

| Customization Capabilities | Yes | Yes | Yes | Yes |

| Production Lead Times | Fast lead times | Fast lead times | Fast lead times | Standard lead times |

| ISO Certification | ISO 13485:2016 | ISO 9001:2015 | ISO 9001:2015 | ISO 13485:2016 |

| Cleanroom Manufacturing | ISO 7 and 8 clean rooms | ISO 7 clean room | Multiple clean rooms | ISO 7 clean room |

| 3M Preferred Converter | Yes | Yes | No: 3M Select Converter | No: 3M Select Converter |

Choosing Between Top Electronics Converting Services

There are several top-rated electronics manufacturing converting services in the U.S. Consider factors like budget, business needs, customer support availability and facility compliance to determine the best option.