Electric motors are everywhere, found in industrial equipment, fans, pumps, compressors, heating and air conditioning systems, and many more. And yet, much of the energy in typical motors is dissipated as heat, friction, and design inefficiency. Energy efficient motors aim to make a difference: they convert more of the electrical energy into useful mechanical power, reducing energy consumption, slashing operating expenses, and shrinking environmental footprints.

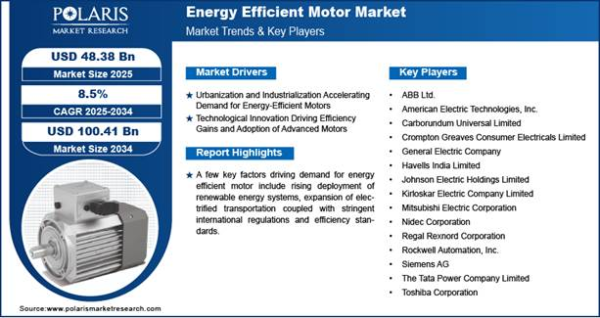

In fact, Polaris Market Research stated that the global energy efficient motor market was worth USD 44.67 billion in 2024 and is expected to increase at a CAGR of 8.5% during 2025-2034.

What is an Energy Efficient Motor?

An energy efficient motor is an electric motor that uses less electricity while providing the same or superior performance compared to traditional motors. Reducing energy wastage through enhanced design and materials, these motors lower operating costs and environmental effects, making them perfect for applications in industries, buildings, and appliances.

Key Benefits of Energy Efficient Motors

Energy efficient motors are increasingly in the limelight as businesses and governments attempt to reduce energy usage, save expenses, and reduce their ecological impact. The salient advantages are elaborated below:

Lower Energy Consumption

Energy-saving motors are crafted to reduce energy loss at work, requiring less electricity to produce the same output. This directly reduces power consumption and helps companies achieve energy-saving goals without affecting productivity.

Reduced Operating Costs

By using less electricity, efficient motors greatly reduce the cost of monthly utility bills. While initially more expensive, the savings from decreased energy consumption over time frequently result in a high rate of return on investment.

Environmental Sustainability

These motors contribute to lower greenhouse gas emissions by using less power, the majority of which continues to be produced from fossil fuels in most areas. Their application facilitates sustainability targets and adherence to environmental policies and carbon-cutting programs.

Improved Performance and Reliability

Constructed with more durable materials and more efficient designs, energy efficient motors usually operate cooler and undergo less wear and tear. This results in more dependable operation, fewer failures, and greater uptime in mission-critical applications.

Longer Lifespan and Lower Maintenance

Since they run more effectively and produce less heat, energy efficient motors tend to last longer than normal ones. They also need less maintenance, decreasing downtime and maintenance expenses over the motor’s lifespan.

Technological Advancements in Energy Efficient Motors

Energy-efficient motors have developed over the years through significant technological advancements that improve performance and minimize energy loss. New levels of efficiency, such as IE3, IE4, and IE5, represent better performance standards. High-efficiency materials such as copper rotors and permanent magnets improve conductivity and reduce heat. Support for Variable Frequency Drives (VFDs) allows motors to run at optimal speeds, saving more energy. Additionally, smart technologies like IoT sensors allow real-time monitoring and predictive maintenance, which is more efficient and reliable.

Energy Efficient Motor Market Factors

- Growing urbanization and industrialization are driving market demand due to increased energy consumption in industry, households, and manufacturing units.

- Technological advances in motor design, control technology, and materials are improving efficiency and performance and driving market growth.

- Growing demand for permanent magnet synchronous motors (PMSMs) will offer new market opportunities.

- Strict upfront costs of energy-efficient motors are deterring small businesses and industries that are price-sensitive.

Future Prospects of Energy Efficient Motors

The market for energy-efficient motors is expected to see tremendous growth as global focus on sustainability and power saving increases. The development of intelligent technologies, including IoT integration and AI monitoring, along with high-efficiency motor utilization such as PMSMs and IE4/IE5 standards, is driving technological advancements and broadening applications. Moreover, advances in motor design and materials, along with the increased application of variable frequency drives, are increasing motor efficiency and performance. Though initial cost is a stumbling block for some, falling prices and favorable regulations will see adoption increase, placing energy-efficient motors at the heart of greener, more efficient industrial and commercial processes.

In Conclusion

Energy-saving motors are revolutionizing industries by drastically cutting energy consumption, decreasing operating expenses, and aiding in global sustainability objectives. With consistent advances in technology, increased demand fueled by urbanization, and more stringent regulations, the market will grow exponentially within the next decade. Though up-front costs are still a deterrent for some, the growing use of intelligent, high-efficiency motors promises not only environmental savings but also long-term economic benefits, positioning energy-efficient motors as a vital element of the industrial and commercial future.

For more information visit energy efficient motor market.