In-Mold Electronics Market: We are all surrounded by gadgets and devices that are smarter and sleeker than ever before. Think about the smooth, touch-sensitive controls in your car or the clean, modern design of your home appliances. What if all of this technology could blend right into the products we use every day, without the need for bulky buttons or wires? This shift is making our everyday objects more functional, but also more intuitive and aesthetically pleasing, making life easier and a lot more stylish.

What are In-Mold Electronics?

In-mold electronics, or IME, is an advanced technology that embeds electronic components, including sensors and circuits, within molded plastic components during production. This allows for touch-sensitive, functional, and sleek surfaces without the added wiring and bulky elements. IME shortens assembly time and improves product ruggedness by integrating electronics into the mold, which makes it suitable for use in industries such as home appliances, consumer electronics, and automotive.

In-Mold Electronics Industry Insights

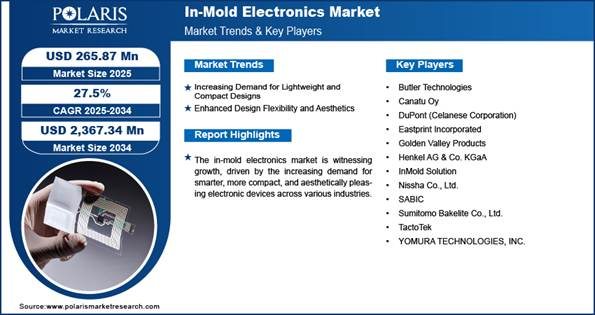

- The global in-mold electronics market is projected to reach a value of USD 208.94 million in 2024.

- From 2025 to 2034, the market is expected to register a CAGR of 27.5%.

- By 2034, the market is forecasted to expand to USD 2,367.34 million.

Applications of In-Mold Electronics

IME isn’t simply transforming how products are designed; it’s transforming entire industries by seamlessly integrating technology into the day-to-day products we utilize.

Intelligent Dashboards and Controls: In the automotive industry, IME is utilized to design sophisticated, touch-enabled dashboards, control panels, and infotainment systems. The embedding of sensors and circuits into molded components enables designs with less complexity and more streamlined forms in automobile interiors.

Home Appliances: In home appliances such as refrigerators, washing machines, and kitchen appliances, IME is designing intuitive touch-sensitive controls and displays. The outcome? Clean, easy-to-use interfaces that are aesthetically pleasing and more durable.

Healthcare Devices: IME is making its way into the healthcare sector, with applications such as smart diagnostic equipment, medical monitors, and even prosthetics. Integrating electronics into medical devices enables more complex functions while keeping the design clean and easy to use.

Industrial Equipment: In industrial applications, IME is employed in machinery and control panels to make interfaces that are more long-lasting and weather-resistant. IME technology is perfect for applications where regular electronics would degrade rapidly or be prone to damage.

Packaging and Consumer Products: IME is also transforming packaging by incorporating sensors or LEDs into packaging materials. This makes interactive, visually stimulating packaging available for numerous applications, ranging from temperature sensors in food packaging to RFID tags for tracking.

Benefits of In-Mold Electronics

IME is quickly gaining popularity in product design because of its many benefits. Some of the major advantages of IME are:

Design Flexibility and Aesthetics

IME enables product manufacturers to create products with smooth, touch-sensitive surfaces, without the use of conventional buttons or parts that are mounted outside of the product. What this creates are slender, more visually appealing products with a minimalist, contemporary appearance. Since electronics can be molded directly into the product, there are fewer design constraints, allowing innovators to have more space to experiment.

Enhanced Durability and Longevity

One of the most notable advantages of IME is increased durability. Placing circuits and sensors inside the molded component, the electronics are less prone to wear and tear, and thus there are fewer possibilities of malfunction over time. It is particularly crucial in products subject to frequent usage or exposed to harsh environments, such as car controls or domestic appliances.

Cost Efficiency and Easy Manufacturing

Integrating electronics into the molding process reduces the need for an additional assembly step, thereby simplifying the manufacturing process. This simplified production process results in cost reductions and quicker turnaround. By eliminating extra parts such as wires, connectors, and circuit boards, manufacturers are able to reduce both material and labor costs.

Increased Functionality and Innovation

IME facilitates incorporating newer features, such as touch input or foldable displays, which will be difficult to do through conventional means. The capability to integrate sensors and circuits within the product itself creates possibilities for innovative functionality that can help improve user experience. This makes it perfect for markets such as automotive, consumer electronics, and healthcare, where next-generation technology and intelligent interfaces are highly sought after.

In Conclusion

IME is revolutionizing product design by effortlessly embedding technology into everyday items to make them smarter, slimmer, and more user-friendly. This new way of manufacturing eases production, increases robustness, and creates new opportunities for functionality, ranging from touch-sensitive vehicle controls to high-tech domestic appliances. Through its increasing usage across sectors such as automotive, healthcare, and consumer electronics, IME is transforming the way we engage with the world around us, laying the foundation for an increasingly connected and streamlined future.