Battery materials and technology company Talga Group Ltd (“Talga” or “the Company”) is pleased to introduce Talnode-R, a proprietary graphite anode product made from recycled lithium-ion battery waste – paving the way for new strategically located battery supply chains.

As energy storage demand surges, Talnode-R marks a turning point in battery material technology. It repurposes waste from two recycling streams, namely anode production scrap from gigafactory waste and spent anodes from end-of-life batteries, to convert into graphite anode suitable for re-use in batteries.

The production process starts with graphite concentrate sourced from battery recyclers, extracted from ‘black mass’ waste streams. Talga then purifies this graphite to battery-grade 99.95% purity using its advanced hydrometallurgical technology, followed by proprietary shaping and coating steps to produce anode that matches the performance of new synthetic graphite anode.

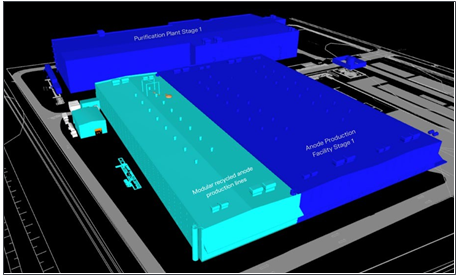

This innovative process not only homogenises recycled graphite into consistent, commercial quality products but also features modular production facilities. This can integrate alongside Talga’s planned natural graphite anode refinery in Sweden (Fig 1) or operate as stand-alone units near battery manufacturing hubs, enabling localised and scalable production.

Multiple global scale battery manufacturers and potential commercial partners are conducting test work and qualification of Talnode-R and discussions are advancing regarding funding and site development in the USA, UK, Middle East and Asia.

Talga Group CEO, Martin Phillips, commented: “Talnode-R perfectly complements Talga’s high-power natural graphite anode production, enabling us to expand globally by deploying modular versions of our European technology. This helps address not only the growing volumes of graphite waste from battery recycling but also closes the loop to create new local supplies of critical graphite anode materials.”

Competitive Position

Talga’s commercial advantage is established through the adaptation of its downstream proven mine- to-anode technology, which supports standalone duplication worldwide. This platform of integrated purification, shaping and coating processes – backed by completed Detailed Feasibility Study (DFS) (ASX:TLG 1/7/21) and Front-end Engineering Design (FEED) studies (ASX:TLG 15/4/24) – has been operational at the Company’s ‘EVA’ anode production plant since 2022.

Utilising its established plant design positions, Talga can capitalise on fast growing graphite waste volumes from battery recyclers across multiple regions, and security and geopolitical impacts driving shifts in demand to non-Chinese anode supply.

Other key competitive advantages include:

- Advanced IP portfolio: The Company’s patented technology platform is being granted in the USA, with patents filed for recycling innovations progressing through IP stages

- Regulatory alignment: Recycling supports EU, U.S, and global supply chain goals, potentially accessing grants and sustainability incentives. It directly advances goals of the EU Critical Raw Materials Act (CRMA), which targets 25% domestic recycling capacity for strategic raw materials by 2030, and fostering of a circular economy.

- Global expansion and feasibility: Internal feasibility studies of UK and Sweden sites, and negotiations are advancing with partners in the USA and Japan for supply, production and offtake. These developments are separate and follow recent joint development agreements (JDA) with Marubeni-SQM backed Altilium Metals (ASX:TLG 27/2/25) and global recycler Aurubis (ASX:TLG 10/9/24).

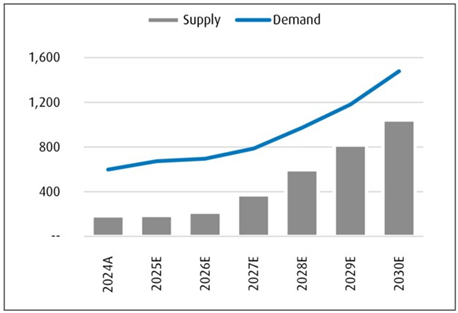

- Boosting resilience and decreasing imports: Recycling graphite anodes offers strategic benefits for supply chain resilience, particularly in Western markets, aiming to cut imports from dominant producers like China. With only a handful of domestic anode operations emerging in Europe and the United States—including Talga’s integrated mine-to-anode Vittangi Anode Project in Sweden—a significant deficit in ex-China supply is already evident and projected to worsen through 2030 (Fig 2).

Development and Results

Graphite constitutes approximately 50% of the active material volume in lithium-ion batteries, being the anode. To date, recycling anode graphite back into a form suitable for re-use in batteries has been hindered by significant challenges, including deep contamination from impurities. Consequently, production scrap and spent anode graphite from black mass is either landfilled and/or burnt off, as it is unsuitable for even low-value industrial uses.

Talga’s scientists developed the Talnode-R product and associated technology over several years. This included completing internal feasibility studies of UK and Swedish sites under the UK-RELOAD Project “Economic feasibility for setting up a recycled graphite anode plant in the UK”. The work formed part of the Automotive Transformation Fund Feasibility Studies: Round 5 competition and was co-funded by Innovate UK, with Class 4 plant and site assessments carried out by Worley Consulting.

In developing the Company’s product, the team collected and processed black mass graphite waste from 5-10 European battery recyclers at the Company’s operations in Germany, Sweden and battery centre of excellence in Cambridge, UK. Talga’s proprietary processing technology, incorporating hydrometallurgical purification and coating stages, successfully regenerated the spent battery graphite feedstock into anode for re-use in Li-ion batteries. This method adapts the Company’s existing alkaline-based process, originally developed for the Vittangi Project natural graphite in Sweden, and has been scaled up from lab to pilot plant (Fig 3).

Material development included characterisation by Inductively Coupled Plasma Spectrometry (ICP), X-ray Diffraction (XRD), Scanning Electron Microscopy (SEM), Particle Size Distribution (PSD) and Brunauer-Emmett-Teller (BET) surface area measurements. Results demonstrated the preservation of graphite crystallinity and interlayer spacing, energy density >350 mAh/g, surface area <2 m2/g, purity in excess of 99.9%C and first cycle efficiency >95% and excellent cyclability, all of which are matching the characteristics of new synthetic anode.

These results are noteworthy as they successfully address the re-use of spent battery waste, which is more contaminated and lower grade than pristine battery manufacturing scrap. Talga is among the first companies globally to demonstrate that spent battery waste graphite can be regenerated for use in EV quality batteries, leading to commercialisation of the Talnode-R series.

Additionally, substantial environmental benefits are gained by avoiding the energy-intensive, fossil- fuel-dependent synthetic graphite production prevalent in China. For instance, Talga partner Altilium has estimated 77% lower emissions for anode production.

Battery Scrap Market

Battery recycling market data from market intelligence firm Rho-Motion shows global Li-ion battery pre-treatment capacity reached 3.5 million tonnes in the first half of 2025. Of this total battery mass, approximately 10-15% by weight consists of graphite anode material. The availability of Li-ion scrap feedstock for recycling surged 40% year-on-year (y-o-y) in H1 2025. Production scrap accounted for 55% of this growth, while end-of-life (EOL) EV batteries contributed 20% to global scrap volumes.

Regionally, Europe experienced a 38% increase in total feedstock scrap volume, driven primarily by production scrap and EOL EV batteries. North America’s total scrap volume rose 49% y-o-y, with production scrap the main contributor, accounting for 56% of total growth (Fig 4).

While production fluctuations in scrap versus end-of-life volumes will occur over time, Talga’s process is robust in its ability to use different feedstocks. It should be noted however that as the global battery market continues expansion for many decades, recycled feedstock will not be able to replace new anode materials entirely and both natural graphite and recycled anode will be complementary in producing the most sustainable long-term graphite anode supply.