WireFlow AB, a provider of advanced off-the-shelf electronics, test equipment and software components for test and measurement applications, announced a project to deliver a system for battery reuse and recycling for EV batteries to KMK Metals Recycling. KMK is an Irish leader in certified resource recovery solutions.

The contract expands WireFlow’s footprint into Ireland, enabling the deployment of its configurable Bifrost system. It also marks the first order for a complete turnkey solution that includes a containerized unit designed to qualify used EV batteries for second-life reuse based on State of Health (SOH) measurements. Batteries that do not meet the qualification criteria will be safely discharged before being sent for recycling.

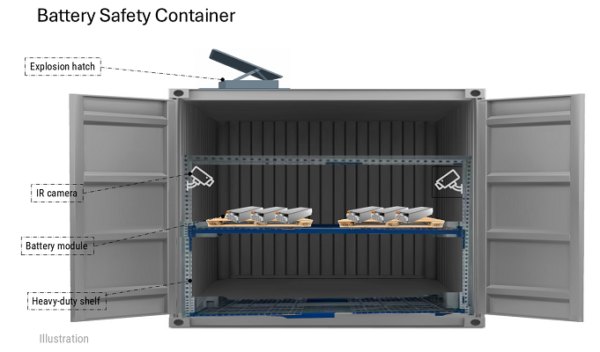

The project’s primary objective is to improve the safety and efficiency of battery discharge and State of Health (SOH) measurement, ensuring controlled discharge to zero voltage (0V) before recycling. Housed in a specially designed 20-foot container, the complete, advanced platform will provide KMK with a secure and accessible environment for battery handling, featuring integrated explosion hatches and infrared thermal camera surveillance to ensure continuous monitoring and risk mitigation during the discharge process- demonstrating WireFlow’s commitment to safety, innovation, and environmental responsibility.

“We are pleased to roll out our first order for WireFlow’s complete Bifrost and storage container system, confirms Mårten Aurelius, Business Unit Manager, WireFlow. Integrating the Bifrost System within a purpose-built 20-foot container offers KMK Metals Recycling a highly specialized turnkey platform that ensures safe battery discharge prior to recycling, precise SOH measurement, and minimized risk of thermal events. The container’s accessible design supports streamlined workflows.”

“WireFlow’s ability to tailor systems to meet bespoke needs demonstrates flexibility and dedication to meeting specific operational needs. WireFlow’s proven track record for reliable solutions, collaborative approach, technical expertise, and strong focus on customer success made us the trusted choice for delivering a comprehensive, safe, solution.”

- The Bifrost solution addresses critical customer needs for safety, reliability, and operational efficiency in battery discharge and evaluation and maintain high standards for safety and performance

- Integrating the Bifrost System within a purpose-built 20-foot container, the project offers a turnkey platform for safe battery discharge, precise measurement, and minimized risk of thermal events.

Kevin Thornton, Battery Department Manager, KMK Metals Recycling, “The integrated container design—with explosion hatches, infrared thermal surveillance, and easy access—allows KMK to carry out high-risk battery discharge in a controlled and mobile environment, improving both safety and flexibility.”

“These capabilities strengthen KMK’s value proposition to clients and partners by demonstrating a clear commitment to safety, sustainability, and operational excellence—key differentiators in a competitive and regulated industry. As a result, KMK is better positioned to scale its recycling operations, attract new business, and lead in a market that increasingly demands responsible and innovative battery lifecycle management.”

Key Benefits

- Ensures safe, efficient, and total discharge of batteries, a critical step before recycling to prevent accidents such as thermal runaway or electrical hazards

- Enhances operational safety and improving traceability through accurate SOH data.

- Provide businesses in battery handling, reuse, or recycling a reliable tool to optimize processes, reduce risk, and uphold safety and sustainability standards, thereby increasing trust and competitiveness in a rapidly evolving market.

“This project provides KMK with a strategic advantage in the growing battery recycling and energy storage market., continues Aurelius. By implementing WireFlow’s solution, KMK gains a reliable and efficient system for complete battery discharge and SOH measurement, ensuring that all batteries are safely neutralized before entering the recycling process. This minimizes safety risks and streamlines operations.”