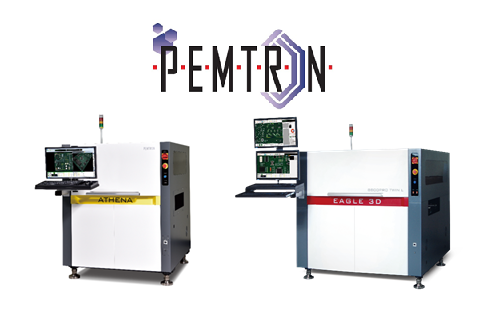

PEMTRON Inspection Solutions at NEPCON Japan:

PEMTRON, an inspection equipment developer and supplier, will exhibit at NEPCON Japan, taking place January 21–23. On display in Booth #E15-8 will be PEMTRON’s comprehensive inspection lineup, including the SATURN 3D SPI, ATHENA 3D AOI, JUPITER AXI, and ZEUS semiconductor packaging inspection system, highlighting inspection speed, accuracy, and production-ready performance.

PEMTRON will showcase the ATHENA 3D AOI System, featuring AI-based inspection capabilities including automatic judgment, auto-teaching, and OCR. ATHENA’s 12-way projection design minimizes shadowing and enables accurate 3D measurement, while simultaneous 2D and 3D inspection supports detailed analysis at resolutions down to 10 microns. Optional enhancements, such as a 12MP camera and three-stage conveyor, further increase inspection speed and throughput.

Also on display is the EAGLE 3D 8800 TWIN, a top-and-bottom, double-sided 3D AOI system designed for efficient inspection of double-sided assemblies. By enabling simultaneous inspection of both sides of the board, the TWIN platform delivers complete coverage in a single pass. An upgraded inspection head improves 3D image stability and accuracy, helping manufacturers streamline AOI processes while improving overall efficiency.

For semiconductor and advanced packaging applications, PEMTRON will present the ZEUS Multi-Functional High-Precision 3D Inspection System. As a versatile all-in-one system for substrate, SiP, and large board processes , ZEUS accurately inspects IC substrate packaging, chip bonding (Die Bonding), and chip alignment precision. A key highlight is its capability for SiP and Large Form Factor (LFF) inspection , equipped with IR penetration technology to reveal hidden defects beneath the surface. This technology detects potential defects in advance , identifying issues such as internal cracks and delamination as well as surface defects like chip/VIA misalignment, edge cracks, and foreign materials.

Rounding out the exhibit is PEMTRON’s JUPITER 3D X-ray Inspection System, which offers both 2D and 3D inspection using advanced PCT reconstruction-based processing. Integrated with PEMTRON’s AOI defect detection algorithms, JUPITER delivers comprehensive in-line inspection and process quality analysis. Seamless data sharing with SPI and AOI systems provides manufacturers with deeper insight into process trends and helps improve overall production efficiency.

For more information, visit PEMTRON at Booth #E15-8 during NEPCON Japan, January 21–23, or visit www.pemtron.com.