The STC3117 is ST’s latest system-side gas gauge integrated circuit (IC) with battery charger control for lithium-ion batteries found in smartphones, media players, digital cameras, and other handheld devices. Very few things are more annoying than having a smartphone claim it has 20 % of battery, only to see it fall to 3 % a few minutes later, just before the screen turns black, and the realization that it was all a lie befalls a user bursting with frustration. In certain sensitive applications, like medical appliances, knowing exactly a battery’s level could be a matter of life and death, and a rough overestimation could place medical personnel in a dire situation.

Regular visitors of the blog will have noticed that ST has a unique leadership in power applications. From extraordinary PFC controllers to apps like Thyristor Finder, which is without competition, to SiC diodes with record efficiency, and new direct converters, ST has a mastery that places it in a league of its own. It was therefore natural for the company to venture into the world of battery management, and the STC3117 is the latest milestone in this odyssey.

From a Basic Coulomb Counter to a Fuel Gauge

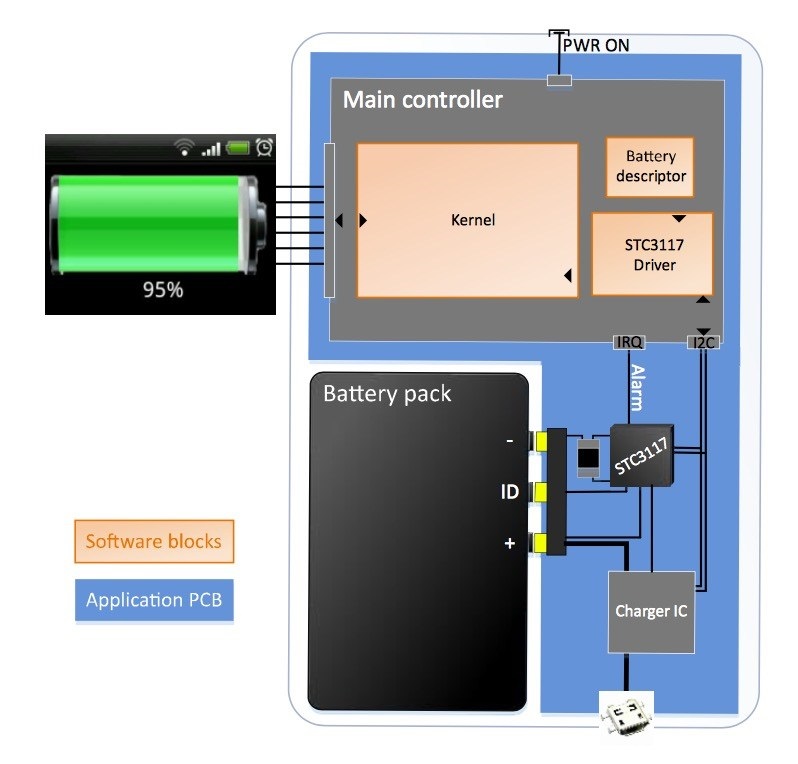

In its most primitive form, a fuel or gas gauge for batteries is a coulomb counter. Since a coulomb is a unit representing an electric charge carried by a constant current of one ampere during one second, it’s easy to guess that a coulomb counter simply measures the current entering and leaving a battery. To get that information, mobile devices will often have a standalone IC that interfaces with the battery, the charger IC, and the main microcontroller (MCU). Hence, the coulomb counter can measure the electric charge carried in and out of the battery to output the State-Of-Charge (SOC), a value in percentage point that will represent the level of charge a battery is holding at a given moment. 0 % means it’s empty and 100 % means it’s full.

Unfortunately, coulomb counting is a fallible method because there is no point of reference. Furthermore, as the battery’s capacity diminishes over time, the counter becomes less reliable. Indeed, counting only works if the system has an accurate view of the total capacity. Hence, a fuel gauge can also determine the SOC according to the battery’s voltage. Since there is a correlation between the voltage and state-of-charge, the gauge can just use a lookup table to determine the charge level after measuring the voltage. This method can even serve to recalibrate the coulomb counter. When the voltage shows the battery is full, the system resets the counter to ensure its accuracy.

OptimGauge: STC3117’s Powerful Advantage

Just like a typical battery gas gauge, the STC3117 continuously measures the current and voltage. However, the component stands above the competition thanks to OptimGauge, an algorithm designed to output a more accurate SOC, thanks to its two modules. The first one is on the chip and keeps track of different parameters such as temperature, current, and voltage, while the second one is on the drivers, and uses information from the former module to dynamically adjust the SOC. The motivation behind OptimGauge’s approach is that it offers new levels of flexibility that can even allow customers to add their own algorithms. Hence, the projects that clients have worked on, sometimes for years, don’t have to go to waste but can be re-used to offer even more precise estimations.

The application processor can even calculate the battery’s State-Of-Health (SOH) from raw information (current, temperature, voltage) to quickly detect if a battery’s capacity decreases at a normal rate, or if the device may require servicing. To top it off, compared to the STC3115, the previous generation, the OptimGauge algorithm used by the STC3117 has been improved to provide continuous SOC corrections for even greater accuracy.

The STC3117 even includes a special alarm output. Basically, a signal sent to the ALM pin can alert the system if the battery is low, meaning that the SOC is below a specific threshold. Such information is absolutely crucial because the alarm can cause the MCU to trigger a shutdown sequence to preserve all the information in memory, and ensure the system’s integrity. ST’s fuel gauge can also detect if a battery is missing, to alert the user, or if there was a swap and the charge/discharge models need adjustments to account for the new cells installed.

Hardware and Software Flexibility

ST’s gas gauge is also highly flexible. Its I2C communication port means engineers don’t have to deal with a specific bus communication, hence the transfer of information between the STC3117 and the MCU couldn’t be simpler. With the new chip, designers can even choose between a mixed mode where coulomb counting and voltage tracking run in parallel and another one that only measures the voltage to save power. Even the level of accuracy is adjustable. Sensitive applications can use a special software layer that takes advantage of dedicated features to increase the SOC’s accuracy, while less critical setups can run without it to save resources.

This flexibility is also manifested in the fact that the Open-Circuit-Voltage (OCV) reference curve is now fully customizable in order to account for the characteristics of the most common lithium-ion batteries. Furthermore, as with the previous generation, the pins for battery detection and charger control are independent, which means it’s possible to use one feature while disabling the other. Finally, the package is smaller (1.5 mm x 1.6 mm, 9 bumps) and the chip’s power consumption is lower, thanks in part to the hardware acceleration of certain computations, like the average current. The generic drivers for the STC3117 are also open source and available on GitHub for added convenience.

To know more about all the other battery fuel gauges from ST, please visit its website.

Author : STMicroelectronics