Haptics technology is bringing to a wide variety of applications the sense of touch, allowing designers to provide users with an immersive and more engaging experience. Consider wearable applications, and how they’re sending us alerts. For example, through different vibrations, your smartphone can let you know that you’ve made a wrong turn on your hike, that you’re falling behind on your targeted pace during a run, or that your boss is calling.

Since wearables are so space- and power-constrained, however, it’s no easy feat to integrate haptics into these designs. One solution to address the challenges is to integrate a power management IC (PMIC) into your design.

Products like wearables, portable devices, and some internet of things (IoT) gadgets tend to spend a lot of their time in standby mode. They may wake from time to time to perform some task. As a result, PMICs for haptic applications need to meet stringent requirements for small form factor and high efficiency. To help extend the end device’s battery life, standby current drawn from the battery should be as low as possible. Based on these parameters, some system designers have determined that the best approach is to minimize their system’s quiescent current by simplifying their power architecture and only incurring the quiescent current of a single converter to supply the whole system. For example, they might designate a single 3V supply for powering the whole system, using load switches to disconnect portions of the circuit to preserve battery life when these portions are inactive. With this approach, however, even though the standby current is minimized, the optimal average current has not been reached because of the higher power consumption in active mode. Average power over the battery charge cycle is not optimized.

Choosing the Right PMIC for Applications with Haptics

Many of today’s wearables utilize eccentric rotating mass (ERM) actuators to create the vibration. Like a regular DC motor, an ERM motor uses the magnetic field of a direct electrical current to move an object in a circle. Linear resonant actuators (LRA) provide an alternative, enabling designers to create more sophisticated vibration signals that convey contextual information to device wearers. LRA uses a voice coil which, based on an AC input, produces a corresponding vibration with a frequency and amplitude that correspond to the provided electrical signal. Compared to ERMs, LRAs are more complex, but LRAs do generally consume less power to produce a vibration. With PMICs, some similar criteria apply; in other words, PMICs that minimize the battery power required to create particular vibrations are optimal.

How can you sufficiently address the power-related design challenges of wearables with haptics functionality? Choose PMICs with:

- Regulators that have ultra-low quiescent current, which reduces standby power for always-on resources, extends battery life, and reduces battery size

- Efficient regulators that reduce active power while also extending battery life and reducing battery size

- Integration to support a sophisticated power architecture in space-constrained designs

- System management, with elements including switching noise mitigation, unified I2C control, integration button/reset control, and a fuel gauge

- A power-efficient haptics driver

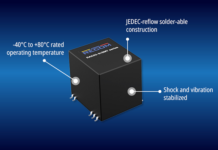

Maxim’s new MAX20303 PMIC is the first on the market with a haptic driver. The MAX20303 PMIC for ultra-low-power wearables features an ERM/LRA haptic driver with automatic resonance tracking. The PMIC’s power management capabilities extend battery charge, and the part is available in a small 3.71mm x 4.21mm wafer-level package (WLP). Other features of the MAX20303 include:

- Micro quiescent current boost and buck regulators

- Integrated linear Li-ion battery charger, micro quiescent current low-dropout (LDO) regulators, and current sinks

- Power on/reset controller, I2C configurability, and optional fuel gauge

The highly integrated MAX20303 is suited for ultra-low-power wearable and IoT applications.

As an example application for the MAX20303, we can consider a GPS sports watch. Here, the MAX20303 can provide all of the power rails for the processor, the sensors, the GPS, and the Bluetooth Low Energy interface. It can also charge the battery, monitor the battery state-of-charge, and provide haptic feedback to the user.

Haptic Technology Growth Opportunities

Researchers at MarketsandMarkets project that the haptic technology market will reach US$19.55 billion in value by 2022, representing a CAGR of 16.20% from 2016 to 2022. Increasing adoption in consumer electronics and also the potential opportunities in medical and automotive application areas are key drivers for this growth, according to the research firm. Underlying technologies such as the MAX20303 PMIC provide designers with one way to overcome the challenges of bringing the sense of touch to small, ultra-low-power electronic applications.