The automotive lighting market is projected to grow significantly. This market is driven by increasing vehicle production, technological advancements in the field of automotive lighting and increasing concerns over safety while driving at night. Light-emitting diodes (LEDs) offer a highly flexible, efficient and compact solution versus an incandescent bulb.

The Comité International Spécial des Perturbations Radioélectriques (CISPR) 25 Class 5 Rated 7.5W Tail-Light Reference Design for Automotive LED Lighting Systems is an automotive taillight, turn-light or front-light reference design that supports a modern power-supply design for an array of LEDs (see Figure 1).

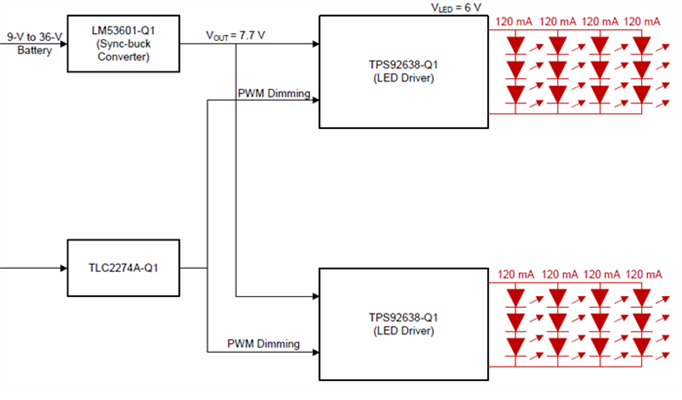

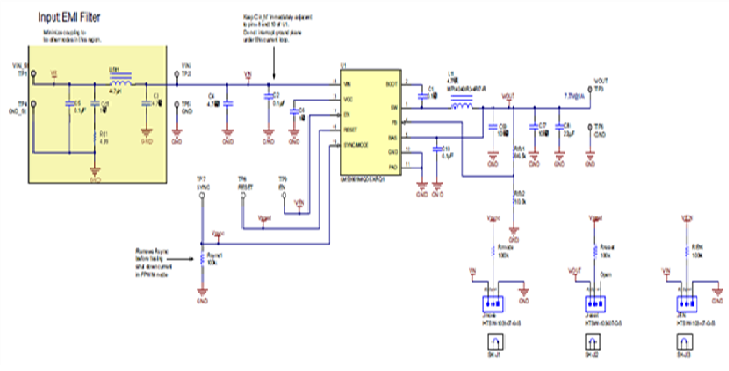

The design uses the LM53601-Q1 as the main regulator connected to the battery after an optimized electromagnetic interference (EMI) filter. The output of the DC/DC converter is then fed to two TPS92638-Q1 LED drivers, which are used to create strings of LED lighting for effects such as turn-light switching or ambient lighting.

Traditional LED designs used low-dropout regulators (LDOs) for the battery regulation to the LED drivers; this can cause power losses, however, particularly during high-voltage conditions from the battery when it is fully charged or transient voltages from a load dump. The LM53601-Q1 is a switch-mode DC/DC converter that offers higher efficiency to help meet tough thermal constraints. LED lighting can suffer from a lot of self-heating issues caused by the LEDs themselves. This is caused by losses inherent in the devices, which can sometimes be quite space-constrained as well. Both of these conditions will cause the internals of the LED lighting design to get hotter than the surrounding ambient temperature. Having a DC/DC converter can assist by making sure that the power supply doesn’t add to this problem. Another benefit is that you need less copper area and board space from a thermal perspective to assist with space-constrained applications.

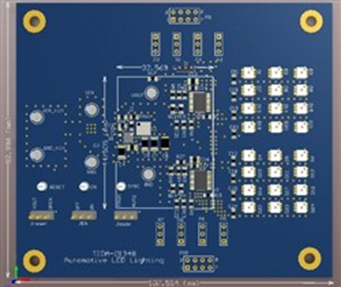

Figure 2 demonstrates the typical area needed for such a solution.

The one challenge of using a DC/DC converter is the electromagnetic interference (EMI) generated by a switching DC/DC converter. The trick to minimizing this problem is to design the switching device to generate as little noise as possible, while also optimizing the printed circuit board (PCB) layout and component selection to minimize the amount of devices to save cost and solution size.

This design is compliant with the CISPR 25 Class 5 rating both from a conducted and radiated testing perspective. This was done to accurately show the size needed for both regulation and EMI filtering, and also to give a fairly accurate bill of materials of the components typically used with the LM53601-Q1. EMI is particularly unattractive in LED lighting because it can cause flickering or distortion to the display. This is undesirable and unattractive and can affect the look and design of a modern automotive lighting system.

Figure 3 shows the full schematic for the EMI filter and LM53601-Q1.

There are many issues when designing automotive lighting designs, the techniques described within this blog covers the implementation of a high efficiency switching regulator to replace more traditional solutions. Using switching regulators can save space, in some case reduce overall cost and can be designed such to limit EMC. Using a device specifically designed for these types of applications can save a significant amount of time, effort and engineering cost. Get more information on TI’s products for automotive lighting applications.